eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

Just a simple question; how old is the fuel in the tank? If it is RON95 and it is 6 months old (which I assume) than it could be easy beyond its best and could have blocked one injection rail by gumming/getting bad.. So injection cleaner in and a healthy dose of RON 98 might help. Fingers crossed, Thom ps: great job! You are correct in your assumption that the fuel is 6 months old. Adding a bit of fresh stuff I will do. I could also run the engine from a fresh jerry can of fuel. When I stripped the engine however, there was no fuel left in the fuel rail. But given me having had these same issues on my first engine with this engine/box loom, to me points me more in the direction of there being a problem with that bit of loom. I guess I just have one more thing to investigate. |

| |

|

|

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

Well, I will start by congratulations with the monumental re-wire eurogranada  All looks good, and nicely laid out as well, so any fault finding or wire tracing should be relatively stress free. As for the compression tests, as long as there is continuity between testing conditions (the whole engine cold and throttle wide open) I wouldn't get too hung up about them being done on a cold engine 👍 The fact the smoke has remained in the loom, and you say you have driven it is also promising. If it was out of sync on 1 bank with the timing chain, I'd expect there to be more mechanical noise from the engine, and certainly not that easy to drive or manoeuvre about Thanks for that! I have personal experience though, of one of these engines running and being "driveable" to the extent of moving under it's own power with a slipped/broken chain on one bank. My first engine upon disassembly turned out to have a broken chain. Yet it had run, badly (worse than the current one) and been driven in and out of the shop like that. But my current line of thinking is that the "new" single color engine/box loom has a problem as this was on two engines that both shared the same rough running and lack of warming up on the same bank of the engine. At least the suggestions on here mean I can get to work. I have some things I can check from fuel and compression to injector signals. |

| |

|

|

|

|

|

Jan 10, 2023 13:16:36 GMT

|

|

Still watching Alex.

Doing some work on my engine last week & I forgot to refit the oil guage pipe - luckily I had to remove the air filter to fix another problem & I spotted it before I cranked the engine.

We all make these silly mistakes.........

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Jan 10, 2023 15:05:54 GMT

|

I know! And that is still much appreciated. My comment in that other thread was by no means a complaint on interest in my own thread (making the assumption that that is why you mention it). It was just my lesson learned. I have had to learn that other people's interest does not necesarily equal many replies. And I'm (now) fine with that. I have also learned that when people feel they really can add something, they usually do. And when I request help implicitly or explicitly I usually am not disappointed. |

| |

|

|

|

|

|

Jan 10, 2023 15:23:57 GMT

|

|

What you have to remember Alex is that so many of us, (or definitely me !!) learn so much from threads such as this, thank you,

The high standards of your work is easy to follow and I think also that your pain and frustration becomes ours,

I have little doubt that you will be successful in finding the issue,

Nigel

|

| |

BMW E39 525i Sport

BMW E46 320d Sport Touring (now sold on.)

BMW E30 325 Touring (now sold on.)

BMW E30 320 Cabriolet (Project car - currently for sale.)

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Thanks for that kind reply Nigel. I just do what I do I guess...

I've owned the car for 18 years now (has it really been zo long??) and I've never given up on her yet, so I will persevere. I'm generally not a quitter anyway...

The story will continue.

|

| |

|

|

|

|

|

|

|

|

Too bad to hear about the issues. And forgetting the oil pressure line is always one of my fears!

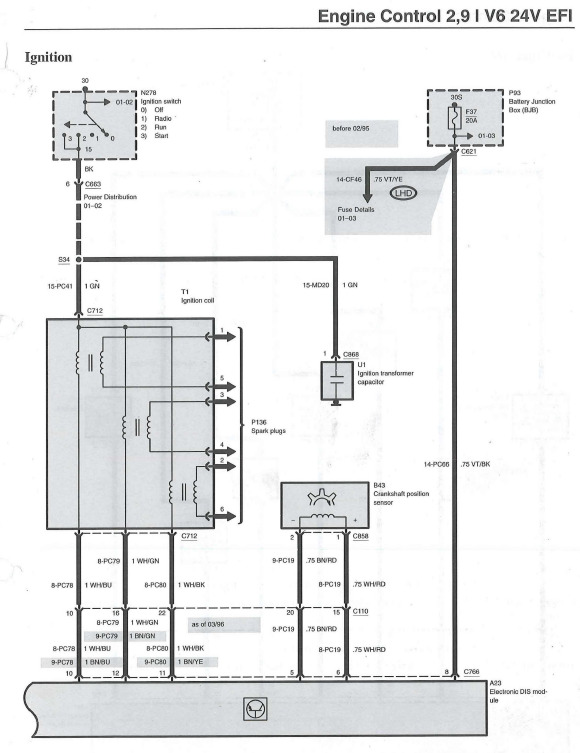

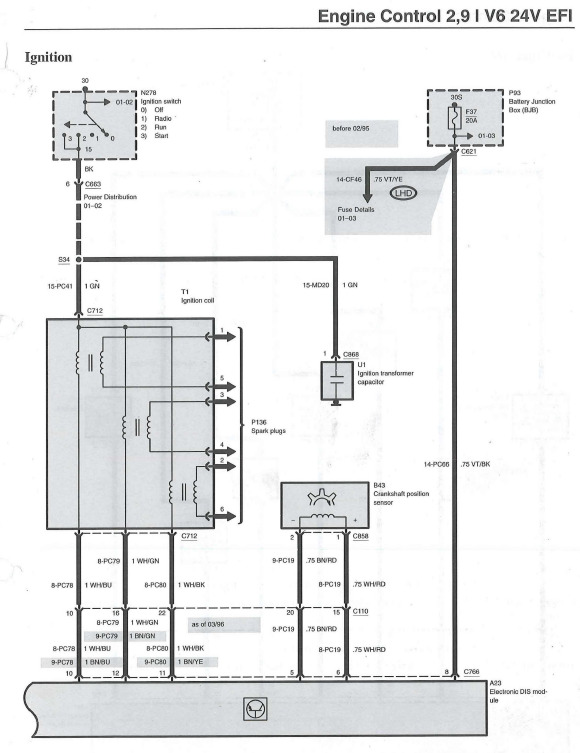

With the EDIS system, you have the cylinders firing in pairs and that means it should be impossible for an ignition fault to make one bank not run (it would fire at least one cylinder).

The coil is (as far as I remember) designed so cylinders 1-5, 2-6 and 4-3 share coils. So the coil should be able to make it run on 2, 4 or 6 cylinders (not 3). Of course, checking spark in all cylinders is of course advisable.

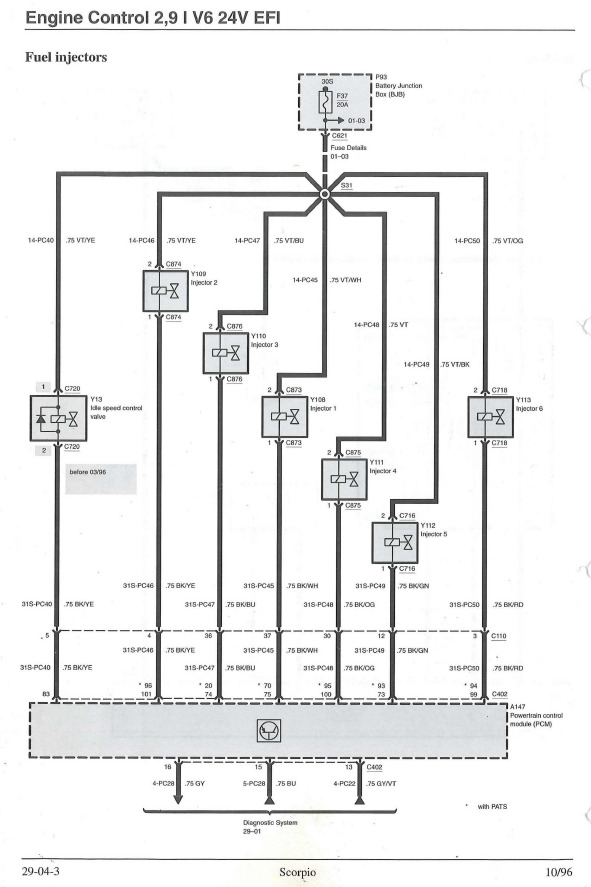

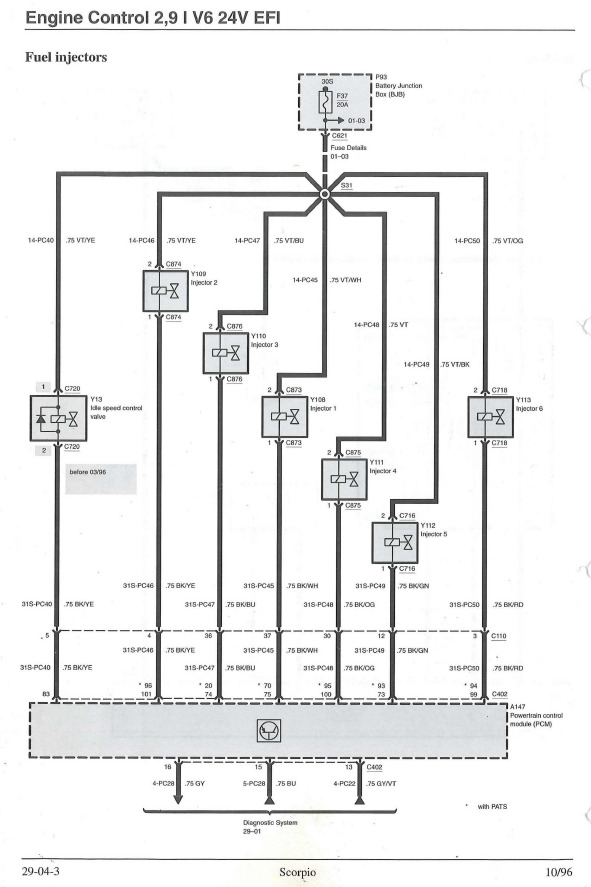

I would suspect injectors first, though. Remind me, does the BOB fire injectors in batches of 3, like the 12V 2.9? In that case a faulty 12V feed to a batch would have 3 cylinders not getting fuel. If they are grouped in banks that would explain one bank not firing.

Gustaf

|

| |

|

|

gess

Part of things

Posts: 220

|

|

Jan 13, 2023 10:51:51 GMT

|

|

Hi Alex.

I have been watching your loom rebuild, what an amazing job you did there. The attention to detail, sourcing all types of connectors and pins, making Excel spreadsheet etc. I am in awe!

I am struggeling to find time to do the most necessary work on my daily, in additiont to family life. How you find the time is beyond me. Not to mention the mojo. I had great plans for this fall, but didn't even get off the starting block.

Sorry to read that you have issues after doing such t thorough job of identifying all of the wires and sensors.

If I understand it correctly, the engine is running on the cylinders, all on one side. Checking if it is fuel or spark related would be my first port of call. If it is fuel related, I would try to assess if it is the injectors, fuelpipe or loom that is causing the problem. Money is on the loom.

If it is spark related, I would check plugs, plug leads and of course the coil. Is it possible to switch over the coil side to see if the other side fires up?

I really don't know these engines and I assume you already have a plan for going forward.

Best of luck. I will be watching in anticipation.

|

| |

|

|

|

|

|

Jan 13, 2023 13:14:00 GMT

|

|

A quick check for injectors is to put an led (with a resistor inline for the led) across the 2 contacts with the engine cranking/running. If it flashes then the injectors are being fired.

If it's on constantly then the injectors are wide open (overfuelling - cylinder will not fire - wet spark plugs).

No light, then you are not getting a signal to injectors.

That will narrow down your search area.

|

| |

|

|

|

|

|

Jan 13, 2023 13:18:40 GMT

|

A quick check for injectors is to put an led (with a resistor inline for the led) across the 2 contacts with the engine cranking/running. If it flashes then the injectors are being fired. Also known (at least on this side of the pond) as a "noid light" to aid searching... |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Hi all,

Thank you for your contributions! I must admit to not having touched the car this whole week, including the weekend. Several reasons for that though. The two most prominent were that one of our dogs had had small surgery earlier in the week and needed constant watch to make sure she stayed away from her wounds (which on sunday we were proven to have failed in after all) and the lousy weather that didn't really provide a dry spell for me to work in. Also, I'd had so much input from all of you that I needed to get my head around that for a bit as well. what do I do first, what is most likely, what is a logical order of testing things given that injector wiring is buried deep under the intake system etc.

I still think testing for spark and compression is a good start. But I'm also more and more convinced of the problem being in the one bit of wiring I didn't build myself given earlier experiences that now can be placed in a different light. I'm also trying to use my photographic evidence to see if I could have made some mistaken in hooking up that engine loom to the injectors. Taking the intake off again is no fun so I'm trying to gather as much info as possible before I decide to do that. So I'm also checking the injector schematics as I know the injector feeds but I do not yet know how the other wire runs in the loom. Are they all connected etc.

So some work to do and then a plan to make...

Besides that I also have to clean the dash panel from the oil spill and start adding in the other circuits that I took out to get the wiring back to its cleanest original state.

So plenty to get on with.

|

| |

|

|

|

|

|

Jan 16, 2023 12:29:39 GMT

|

|

I read my diagrams again, and generally, the V6 is wired such that the black 12V feed to the injectors, is one wire from the loom that splits into the 6 injectors "in the valley" between the cylinders. The brown wires that the ECU grounds to trigger the injectors are grouped 3 and 3.

If 3 injectors are not firing, I would thus first suspect that the brown wires to a set of injectors are not connected. Of course, using a LED to check an injectors is quiet easy but you might also want to check just for 12V with key on to isolate the issue a bit.

Gustaf

|

| |

|

|

|

|

|

Jan 16, 2023 12:39:31 GMT

|

|

Rather than pulling the plenum off you should be able to check there is resistance and therefore continuity across each injector at the ECM connector, if you can get a test wire in the back of the connector you should also be able to check there is a signal being fed to each injector with the engine running.

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Jan 16, 2023 14:53:08 GMT

|

I read my diagrams again, and generally, the V6 is wired such that the black 12V feed to the injectors, is one wire from the loom that splits into the 6 injectors "in the valley" between the cylinders. The brown wires that the ECU grounds to trigger the injectors are grouped 3 and 3. If 3 injectors are not firing, I would thus first suspect that the brown wires to a set of injectors are not connected. Of course, using a LED to check an injectors is quiet easy but you might also want to check just for 12V with key on to isolate the issue a bit. Gustaf This is the 24v ignition circuit.  This seems to confirm what has been said regarding cylinders being paired as far as ignition is concerned. But also, if the ignition is obviously working on one bank, should it than also not be working on the other? This should be relatively easily confirmed. At least this confirms I have everything exactly in order on my bit of new loom. The only thing I have trouble reading is splice S34. This is obvioulsy traced to the ignition switch. But, ALL wiring to the engine and gearbox go through C110 and C113, these are the main connectors. So that wire should be in either C110 or 113, but I cannot determine that from the view. But C110 only has a ground (as far as I know) on pin 27 and a 12v feed on pins 28 and 38. All other wires either go to a sensor, injector or the ecu. C113 has a ground on pin 4 and 12v feeds on pins 5, 16 and 26. This is the injector circuit.  Again this confirms I have the right wires going to the right pins on my bit of loom. And again there's a splice S31 where I get lost. Obviously I have the original engine/box loom still so I will check that to see how and where the injectors get spliced to one wire. But I think this means that they will probably all work. What I suspect is that two injectors have gotten mixed up when this bit of loom was made. Causing an injector to fire when there is no spark in that cylinder. I can check my own work obviously, but I think I'll need to trace the wires from C110 to the injectors as well which will necessitate the removal of the intake again. But first I think I'll do the compression check to be sure of compression, check for spark to be sure there is one for each cylinder (pair), see if I can get anywhere with the led suggestion I have received from different people. And go from there. But I think I won't get away with a better check of the injector [ortion of the installed loom. |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Jan 16, 2023 14:58:24 GMT

|

Rather than pulling the plenum off you should be able to check there is resistance and therefore continuity across each injector at the ECM connector, if you can get a test wire in the back of the connector you should also be able to check there is a signal being fed to each injector with the engine running. Thanks for this addition. SamJ and I also discussed similar methods. But as the loom was tight to fit, I also need to make sure the injectors actually fire, even if signal comes all the way to the main connectors. Perhaps the tightness of some of these connectors has broken a contact. But then again, the resistance should then differ from others I guess. |

| |

|

|

|

|

|

Jan 16, 2023 15:15:01 GMT

|

|

The noise capacitor (the one that is connected to S34) has been just next to the coil in all the EDIS looms I have worked with. But yes, it is "impossible" to have spark on only one bank or only 3 cylinders on an EDIS6.

The injector wiring is different from the BOA and others, suggesting Ford may have left the batch firing system. If the wires are indeed as the diagram, that means anything from 1 to 6 injector wires may fail (unless they are grouped 3 and 3 to 2 injector drivers in the ECU itself). So yeah, checking compression and the actual signals at each injector is necessary I would say.

Gustaf

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Jan 23, 2023 11:00:04 GMT

|

|

Another week has gone and the report is mostly the same asl last week. I didn't do much if anything on the Granada. With the exception of starting it up and coaxing it out of the garage and later in the day back in again. It stil starts without frying things. It still runs like curse word. And I haven't done anything to check out why. It's just too cold and we had a couple of days of snow as well.

I did improve on the lighting in the garage though. For the last month I think the two fluorescent lights in the garage were playing up. At first it was just one failing to light when asked, but doing so after a wack on the housing. Then it failed completely and shortly thereafter the second one failed as well. This has always been an issue as long as we have lived here (despite verifying the wiring is 100%) so I was not ready to invest in new tubes, but I figured I'd better change them over for LED versions. And instead of two I bought four. Three for the main lighting and a fourth to replace the old fluorescent tube above my workbench. It's annoying how long that one takes to light (I'm more then once done in the garage by the time it's well and truly on if I only have to get or stow away something) and at 16 euro's well, it's a no brainer.

Got the three fitted and now have a sea of light again. The one above my workbench requires some more work so I didn't start that job just yet.

So now I can see more when working in the garage.

Also still a little hesitant to get going on the trouble shooting. I'm not sure yet if it's the abundance of tips (some of which are more in my skillset than others) or just the lousy cold weather. If I can't get myself going again when the weather improves, I'll ask for help from Sam as then I can't whimp out, lol.

|

| |

|

|

|

|

|

Jan 23, 2023 13:20:25 GMT

|

|

Alex,

Do the led test on the injectors first - it's quick and easy and will tell you a great deal.

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

Alex, Do the led test on the injectors first - it's quick and easy and will tell you a great deal. Thanks, I'd like to do so yes. I even did some prep work, but the conclusions put me off a bit. It was said I could check the injector wiring for signals/resistance from the ecu and then down the line through connectors to the injectors themselves as a final destination. But I cannot safely get something into the connectors at both ecu and the main junctions. It's all rather tight with the wire thickness, the waterproofing pads and the deep seating of the connectors. And to reach the injectors themselves means taking off the entire intake system again. Which in itself is quite a job, although I'm "trained" in that one. So I can either think of using a pin or needle of some kind to push through the insulation on those wires or perhaps a multimeter like tool that can sense what the wire is doing by isolating it and putting it in its jaws (I've seen a friend use one but not sure exactly what the capabilities are). |

| |

|

|

spot

Part of things

Posts: 105

|

|

|

|

Alex, Happy to read the car still starts and runs - Sorry to read you are still having issues after such attention to detail... I wondered if you had any spare C110 connecters (populated with pins) that you could fashion an 'interuptor' that woud allow you to probe the signals more simply. Without an availbale connector, only pins; could you perhaps fashion 'pigtails jumpers' to breakout the connector block? "Wear two jumpers and get back out in the garage you ***!"  |

| |

|

|