eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

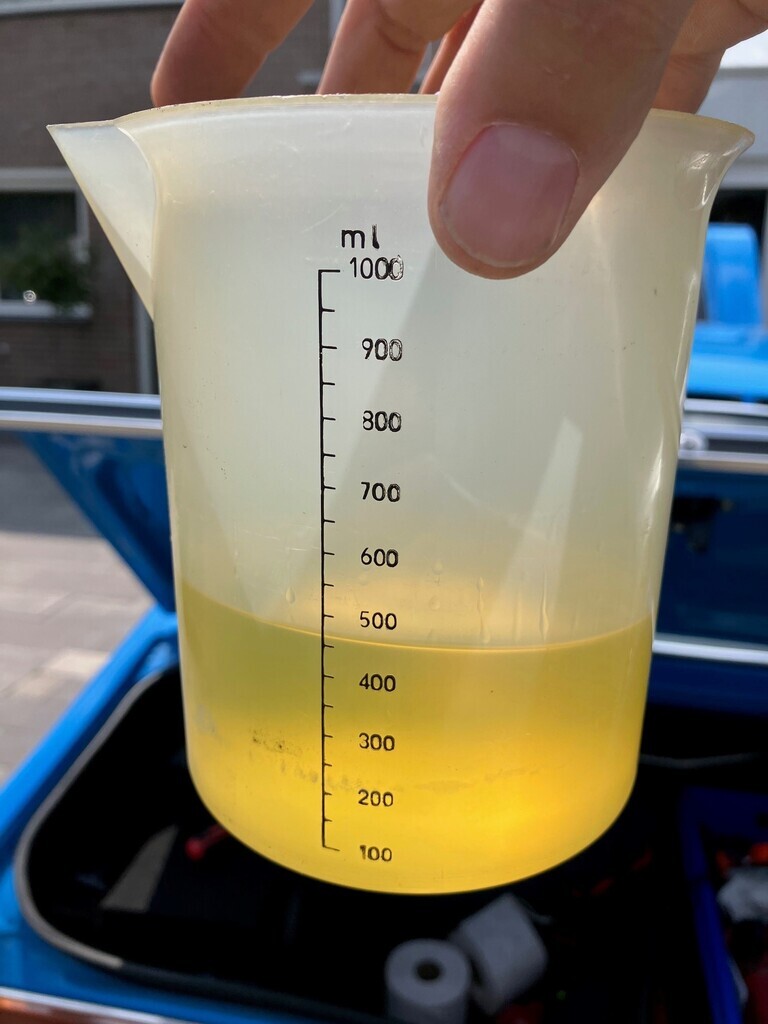

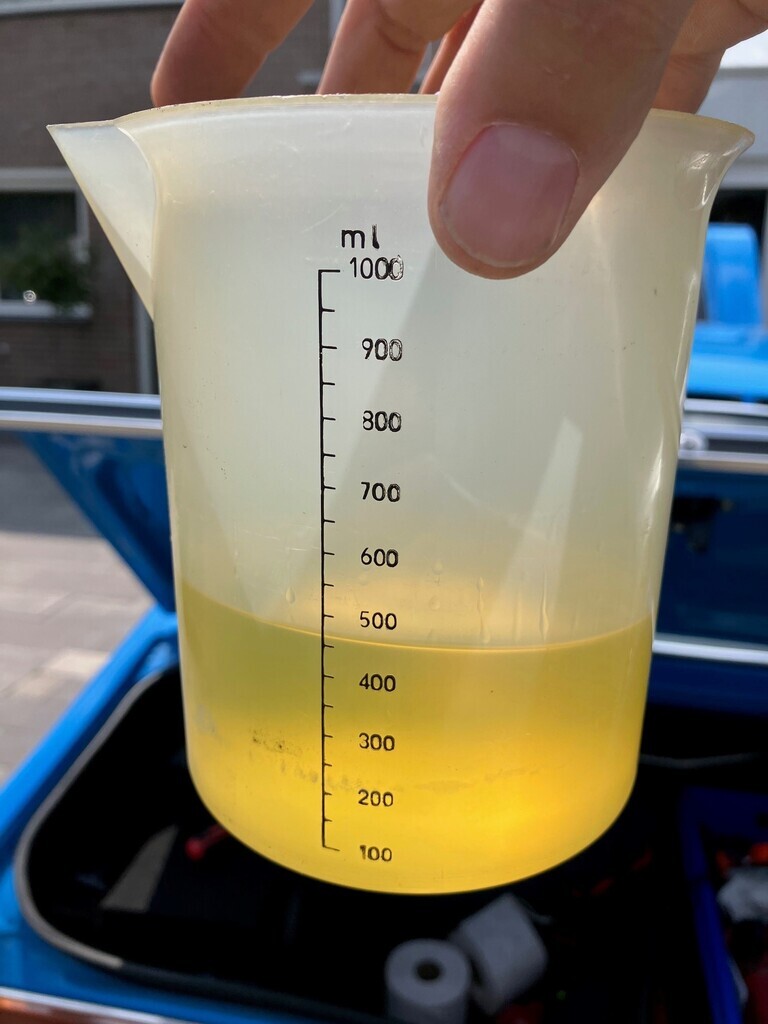

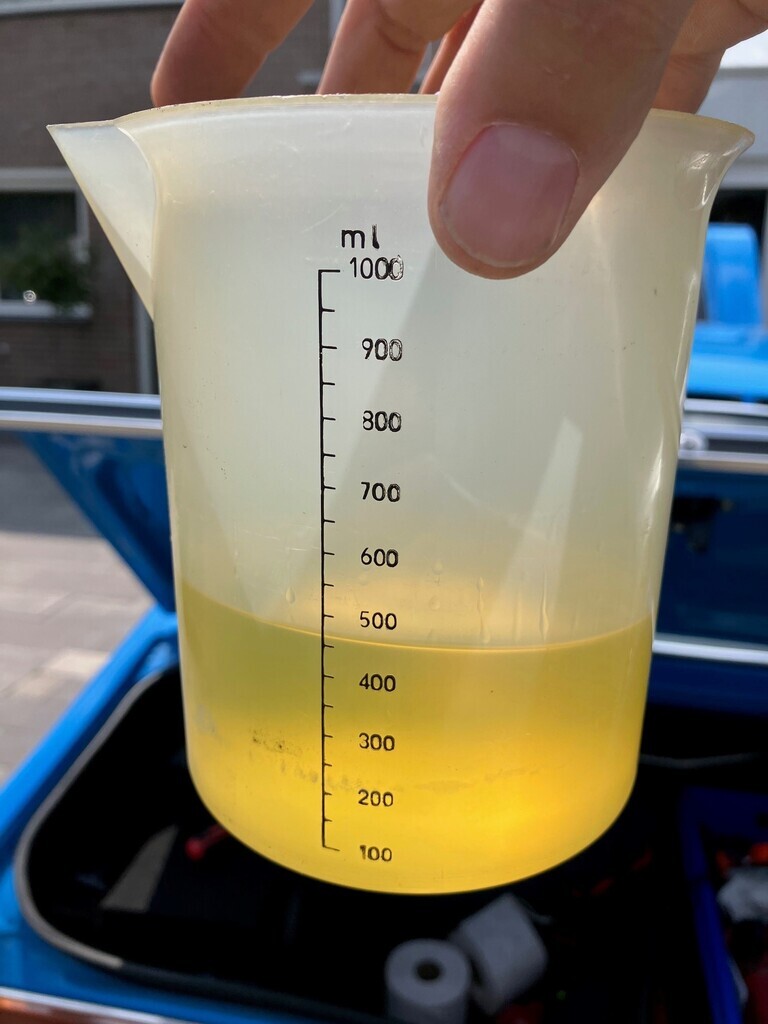

So I did some troubleshooting based on all of the above. Fuel system first as that I think is the main reason the car is cutting out when hot. I started checking for fuel flow. The first check I did was the return at the tank. I started the engine and looked to see if I could see any fuel going back to the tank (due to the way it is plumbed). I couldn't visually verify. So I undid the return line at the tank and extended it to reach a bucket. First I just watched the flow and was disappointed. So I decided to do a measurement. Timing a minute of engine running.... It was too difficult to isolate the two pumps from eachother as they are fed by the same wiring. The Efi pump I could have hooked up to a battery directly, but at the back that would have menat finding a way of getting 12v to a wire that is hard connected to the pump end bit. So keep this in mind. I got a staggering 450 ml. Where something around 2-2,5l were expected.  See this video for the flow: As this was way below expectation I changed out the filter at the tank end... the result was surprising.  I guess the filter was more contaminated than I figured. Very fine dust like grit came out of it.  So now I had at least double the flow, but it still is meagre. I next checked the swirl pot connections. I do indeed fill it bottom to top from the fuel tank, and one of the upper side connections is the return to the tank. So in theory only when the swirlpot is full it will cycle back to the tank. The efi pump picks up on the bottom as well and the return is the other upper side connection. I next checked the efi pump flow including the fuel filter. This pumped a liter in a matter of seconds. I never did a fulle measurement as I was quite satisfied that this flow was more then enough. Next I swapped the pumps again. The wiring and lines were matched better to the old/originally used one. I again measured flow and this, though in my perception just a little slower than the other, was also filling the bucket at speed. So I don't doubt this flow for now. With everything buttoned up I took the car for a drive. It was still quite a hot day and after this trip the fuel pump was a lot less hot, more in line with hand warm as Kevins had said before. Though the swirlpot itself had quite some heat in it. The under bonnet temp with a BOB engine is not/never low. Everyone I know seems to think they could do with running a bit cooler. I'd like to check for air in the coolant system, but not sure how. Weird enough, this fuel pump makes the engine run smoother. With the other it hunted a little bit at times. So I guess doubling the flow has improved the heat situation some. But to me it is proof that I can do better. A side effect is that the fuel pump at the rear is now more audible, like it is doing it's job better... I checked the line thicknesses from the swirl pot and the EFI has a 12mm pickup and an 8mm feed to and from the engine. This 8mm corresponds with the diameter on the feed lines to both the pump and the BOB fuel rail. No issue there I think. The line thickness to the tank and back was 6mm, which means that at the point where the hard plastic line goes to the rubber sections, the inner diameter is even smaller. So I'm thinking of upgrading these bits to 8mm. I did manage to lose my fuel cap as I figured I had it all bottoned up but the cap apparently was not on (and must have been on the rear glass when I went for my test drive). Have to source a new one... |

| |

|

|

|

|

|

|

|

|

|

|

Great, sounds like you are getting somewhere.

I spent some time going back through your thread and noticed you had dirty tank issues before as well, so this all matches up.

For reference, your 450ml in a minute is not enough to fuel the BOB at full chat, so any full power running empties the swirl pot. The 800ml/minute is also still borderline. I'd expect you to need around double that to ensure you are always flowing enough fuel to through the swirl pot in the low pressure circuit.

So knowing this, I'd try to get the fuel flow through the swirl pot up some more; is there a filter sock in the tank that could now also be clogged? If not, try a different pump and indeed up the line size to 8mm. Nylon air line from ebay/amazon works great for this and is actually fuel (and ethanol) resistant. At a push, you can also use your spare injection pump to feed the swirl pot. Just ensure that pump is below the fuel level as they don't pull much of a vacuum. That gets rid of the annoying clickety clack of the red top pump as well.

|

| |

|

|

|

|

|

|

|

|

Nice finds.

I have entirely stopped using those small filters on anything near an EFI engine. I use a regular EFI filter between the lift pump and catch tank, the filter area is many times larger and I think that is vital.

I do think 8 mm lines from the rear of the car to the front might help but I would also think about just replacing the lift pump with a new one. If it has been struggling for some time it may well be worn...

|

| |

|

|

|

|

|

|

|

Had a thought last night which might be helpful to persuade you to re-think the whole setup. Did you realize that where the catch tank is now it is highly likely to be pierced in a minor impact? With possibly devastating results (= fire). Looking at the amount of trouble you're having with the tank & setup, I'd still seriously consider modifying the tank to feed a single pump. It needn't be too difficult. www.summitracing.com/parts/sum-290304edit: or even this: www.amazon.com/SMALLFATW-Integrated-Dual-Port-Cummins-Powerstroke/dp/B085D8DG47/ "no tank drop installation". Sell off the setup you have now and it'd cost next to nothing. |

| |

|

|

|

|

|

Jun 27, 2023 11:21:55 GMT

|

|

It looks like you have got to the bottom of what is causing the running issues, The simplest solution would be to get someone to braze flange on the top of the tank and fit a range rover classic efi in tank pump unit which costs around £50. If there is a is enough flat area in the top of the tank you can even do it with a loose flange fitted to the inside of the tank.

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Jun 27, 2023 14:45:32 GMT

|

|

A quick reply to the last few additions... an appology before hand if I sound like a know it all here...

The filter after the tank was there from before when the tank was still uncoated. I think it now mainly caught debris that was still in the system. The tank still looks good as far as I can peer into it. So I may just remove it now as the other system has its own filter.

I can verify the operation of the lift pump when I increase the line size. In all honesty I consider that the easiest option. It leaves everything as is but should help solve the problem. I could consider using the second efi pump, but I'd have to find a way to go from 8mm fitting at the tank to the 12mm of the pump. So I'd only do that if the pump test warrants that.

Having coated my tank at some expense I'm just not keen on doing any mods to it. Dropping in a pump from above requires a flat surface that I'm not sure there is, also the tank is pressed against the floor of the boot so the space for the outlet is also a problem. At the very least it would lower the tank some. But adding this does nothing to stop fuel from sloshing to one side in a corner starving the pump. There's nothing in the way of baffles in the tank it being a "carb" version. But it's at least easier than adding the other suggested items. One is a weld on, but doesn't seem to be able to hold much fuel in a corner at low tank either, so I don't see the benefit really. The other item I don't quite see how it should work.

My thinking is just increasing volume of flow by increasing line size as a start. The safety aspect of having a swirl pot at this location has never really bothered me too much. Even the MOT man has never said anything about it's location. An accident can always happen obviously, but there's some room around the tank in case of an accident. I agree having it elsewhere could be safer but I can live with this. At least it hasn't been on my mind before while driving. I myself adjust my driving to the vehicle, keeping more distance etc. but you can never fully discount a momentary lapse of yourself or another traffic participant .

|

| |

|

|

|

|

|

|

|

|

I agree that it is nice not having to modify the tank itself.

I think I have mentioned that in my Capri I use a Volvo 740 in-tank pump as the lift pump, it is small enough that it fits through the sender flange opening and it has been working great for many years now. The benefit over a "generic" low pressure pump is that it is OEM quality, has a greater flow and also a tidy installation. Might be worth considering for future upgrades.

As for the safety; a fuel tank in itself is not a big deal, it is fuel vapor and spray that ignites easily and having a swirl pot or catch tank of a litre or so up front wouldn't concern me too much. The reason I moved mine was more that I needed the engine bay space...

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

I agree that it is nice not having to modify the tank itself. I think I have mentioned that in my Capri I use a Volvo 740 in-tank pump as the lift pump, it is small enough that it fits through the sender flange opening and it has been working great for many years now. The benefit over a "generic" low pressure pump is that it is OEM quality, has a greater flow and also a tidy installation. Might be worth considering for future upgrades. As for the safety; a fuel tank in itself is not a big deal, it is fuel vapor and spray that ignites easily and having a swirl pot or catch tank of a litre or so up front wouldn't concern me too much. The reason I moved mine was more that I needed the engine bay space... Did the volvo pump fit without modifications then? I'm not familiar with the 740 pump and ggole shows me several versions, so I need more info to understand. Care to elaborate? In the granada the sender with the fuel pickup/outlet is located in the bottom of the tank so how do you get the volvo pump in and the original sender as well? Did you cut the original pickup pipe short to put the pump on it or something? Do you still need a swirl pot as just this mod wil not prevent the pump from running dry in a corner with low fuel level in the tank. |

| |

|

|

|

|

|

|

|

|

It might have been a Volvo 940 pump too. Anyway, some of them have a "Walbro style" intank pump that I think feeds the external high pressure pump. It is something like 38-40 mm diameter and quite small.

I cut the pickup pipe shorter and the pump rests on the tank bottom. The electric wires pass through the old return fitting (since newer Capris had a return fitting also on carbed cars).

Since I still use the external catch tank/swirl pot, I never bothered to add baffles, and it seems to work fine anyway.

It is one way to do it, but of course adding baffles is a good idea but then you are in tank cutting territory.

|

| |

|

|

|

|

|

|

|

A little more info on the additional sumps and how they work; the idea is that both feed and return go from/to the sump, so the only thing needing to be replaced from the main tank is the engine's fuel consumption. So a little goes a pretty long way. The bolt-on one is pretty simple; drill a large hole, insert the threaded plate through said hole and bolt sump on from the bottom. The rubber gasket seals it. I've got a similar but homemade setup on my car (an EFI converted Alfa 105) after struggling with oem in tank pickups and pumps (sounds familiar right? ;-))  Since adding that wart, all has been fine and I've no problems running the tank near empty. But I fully get your point on not wanting to cut into the coated tank. All might be well with just a better performing lift pump system, so indeed why not try that first. |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

It might have been a Volvo 940 pump too. Anyway, some of them have a "Walbro style" intank pump that I think feeds the external high pressure pump. It is something like 38-40 mm diameter and quite small. I cut the pickup pipe shorter and the pump rests on the tank bottom. The electric wires pass through the old return fitting (since newer Capris had a return fitting also on carbed cars). Since I still use the external catch tank/swirl pot, I never bothered to add baffles, and it seems to work fine anyway. It is one way to do it, but of course adding baffles is a good idea but then you are in tank cutting territory. Thanks. I get it now. But in that case it is just as easy to use the second efi/bosch pump outside of the tank. |

| |

|

|

|

|

|

|

|

|

Just be aware that a Bosch EFI pump does not really like to "suck" from small bore lines into the fuel tank. It is not great to use as a lift pump IMO.

One of the reasons for my choice is that the pump is used more or less as designed.

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

A little more info on the additional sumps and how they work; the idea is that both feed and return go from/to the sump, so the only thing needing to be replaced from the main tank is the engine's fuel consumption. So a little goes a pretty long way. The bolt-on one is pretty simple; drill a large hole, insert the threaded plate through said hole and bolt sump on from the bottom. The rubber gasket seals it. I've got a similar but homemade setup on my car (an EFI converted Alfa 105) after struggling with oem in tank pickups and pumps (sounds familiar right? ;-))  Since adding that wart, all has been fine and I've no problems running the tank near empty. But I fully get your point on not wanting to cut into the coated tank. All might be well with just a better performing lift pump system, so indeed why not try that first. Thanks for your continued feedback! I guess I just didn't fully understand how that bolt on one was to be mounted... Now I do and I quite like the idea of it. It would simplify the system by using only one suitable pump, would lose the swirl pot as well and improve safety a bit as well. I still don't like the idea of cutting a hole in the tank to fit it. I also need to see how mcuh lower it would be and if that could become an issue. But I should consider it. I do feel the one you used looks bigger, the one you linked seems small and I have my concerns of it being able to always feed the engine. On the other hand the return schould mean fuel is always supplied back at the same point. I may be crazy but I wouldn't really consider my current issue a struggle with pumps, pickups and sumps. The system has worked for 7 years without fail, and for all intents and purposes it may be perfecty functional as is now I changed the filter out and the flow has doubled again. It may have been meagre all along, but it never stranded me until recently and I now feel that was due to the reduced flow causing extra heat. I just consider all this trouble shooting and the result an improvement. And this is where it gets a bit difficult. I have the easy option of just upgrading the lines (which in itself poses some qestions) or modifying the system according to your suggestions at the tank. Upgrading the lines raises the following thoughts: I don't like long rubber lines so I'd need to find a 8mm inner diameter plastic hard line. But my experience with hardlines is that it's tougher to put fittings on. You can't use slide in stuff as the plastic won't stretch. So what fittings do I use? I mean I need to go from the 8mm pickup to the pump and from the pump to the hardline and back to a flexible one to the swirl pot. I now use these and they work well so far, but officially these aren't for fuel lines.  Fitting the other solution would also require new lines as they'd have the same diameter issue. Further fitting should be simple enough and the only variable is having or finding the right size hole cutter. |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

Just be aware that a Bosch EFI pump does not really like to "suck" from small bore lines into the fuel tank. It is not great to use as a lift pump IMO. One of the reasons for my choice is that the pump is used more or less as designed. Yeah that was offered up before, so something to consider if I decide to go that route. Edit: On second thought, the bosch efi pump I use is used in the MkI scorpio outside of the fuel tank to supply the 2.8/2.9i engines. So this pump should be ok with drawing fuel from the tank and supplying it to the engine pressurized. |

| |

|

|

|

|

|

|

|

|

For most of my plastic fuel lines I use normal hydraulic fittings, for pressing hydraulic rubber hose on with a "sleeve". The barbs are enough to hold a plastic fuel line just fine (it just taps on, tap the fitting with a hammer, the line can be held between two wood blocks with a suitable groove in a vice). I have also used pneumatic quick connect fittings for years with no issues - just make sure to use good quality fittings.

|

| |

|

|

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

|

|

|

You can also use 8mm Cupro Nickel brake pipes for fuel lines. It's what I have front to back on my Avenger. You can use a brake flaring tool to put a small flare on the ends and then put your rubber hose over with a hoseclip as normal. I haven't had any issues in 4 years using this method, although nylon is no doubt easier to route. You do need a pipe support at regular intervals though, although that would be best with whatever material you choose.

|

| |

|

|

|

|

|

|

|

|

or you could go for AN6 PTFE, pretty expensive but probably the easiest to thread through and should last pretty much indefinitely.

Personally I wouldn't get too hung up on the safety aspect of the swirl pot, the fuel tank is in a similar place to a Pinto after all, it is what 50 year old cars were like and is a personal choice on how much risk you want to take, much the same thing as riding a motorbike or horse.

|

| |

Last Edit: Jun 28, 2023 9:31:23 GMT by kevins

|

|

|

|

|

Jun 28, 2023 10:22:35 GMT

|

You can also use 8mm Cupro Nickel brake pipes for fuel lines. It's what I have front to back on my Avenger. You can use a brake flaring tool to put a small flare on the ends and then put your rubber hose over with a hoseclip as normal. I haven't had any issues in 4 years using this method, although nylon is no doubt easier to route. You do need a pipe support at regular intervals though, although that would be best with whatever material you choose. Nylon tubing is only easier to route if you don't need tight radius bends like around chassis rails or out of equipment. Having plumbed a number of fuel systems with it, I haven't yet found a DIY method of forming it like factory parts. You can fit factory fittings into it using a heat gun, and it's now possible to buy replacements easily and cheaply. If you can manage without tight bends, nylon is quick, cheap and easy to use which is probably why it's been used for about sixty years. I don't like the possibility of fuel leaks, let alone high pressure ones, so prefer having the fuel lines with as few joins as possible. Which is why I would always go with a submerged fuel pump instead of lift pumps to an external swirlpot. Again they've been OE for ages, so you'd need a seriously powerful engine to have to resort to some of the fancy aftermarket solutions. Here's an Avenger tank modified to take an OE pump/swirlpot/gauge sender/return  The clamping parts I made to weld onto the tank  And the pump itself; a brand new Range Rover part that was £50 including the sealing ring. I did have to shorten the posts and internal feed pipe:  |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

Jun 28, 2023 13:29:22 GMT

|

You can also use 8mm Cupro Nickel brake pipes for fuel lines. It's what I have front to back on my Avenger. You can use a brake flaring tool to put a small flare on the ends and then put your rubber hose over with a hoseclip as normal. I haven't had any issues in 4 years using this method, although nylon is no doubt easier to route. You do need a pipe support at regular intervals though, although that would be best with whatever material you choose. Nylon tubing is only easier to route if you don't need tight radius bends like around chassis rails or out of equipment. Having plumbed a number of fuel systems with it, I haven't yet found a DIY method of forming it like factory parts. You can fit factory fittings into it using a heat gun, and it's now possible to buy replacements easily and cheaply. If you can manage without tight bends, nylon is quick, cheap and easy to use which is probably why it's been used for about sixty years. I don't like the possibility of fuel leaks, let alone high pressure ones, so prefer having the fuel lines with as few joins as possible. Which is why I would always go with a submerged fuel pump instead of lift pumps to an external swirlpot. Again they've been OE for ages, so you'd need a seriously powerful engine to have to resort to some of the fancy aftermarket solutions. Here's an Avenger tank modified to take an OE pump/swirlpot/gauge sender/return  The clamping parts I made to weld onto the tank  And the pump itself; a brand new Range Rover part that was £50 including the sealing ring. I did have to shorten the posts and internal feed pipe:  I can get away with nice easy curves for the routing of the fuel line. I routed them to suit the ability of the lines to bend. I get all the possibilities and relatively low cost of modifying a fuel tank. I wasn't comfortable with it back then and would probably still not be completely. But like I said. I have invested in coating my tank and wouldn't want to risk that by doing welding to it now. Also, the top of the tank is ribbed and that means more work/trouble than just adding a simple flange on a flat surface. |

| |

|

|