An update of sorts to tie all the loose ends up and well, create some more of course. Probably going to get pretty rambling so just take a look at the pictures if you can't be bothered reading.

The car is finally on the road but not without last minute hicups that we are all so familiar with.

I arrived at the workshop the evening before the MOT to do some last minute checks as you do, got to make sure the indicators flash and that the brakes aren't binding and such, only to discover a flat tyre, gah.

The valves on the new rims are of the bolt in type and seems like I didn't install this one as tightly as I should have. A trip to the tyre fitter was a no go as they only open 9am to 3pm, (it's worth noting here that summer in Norway means shorter opening hours or indeed closed all together in some cases, more of this later) So I pumped it up and hoped it would be able to hold enough air to get me to the test station and back again the next day.

With air seemilgly staying where it should be for the time being it was out for a, say it quietly, illegal test drive. No registration plates means no insurance here.

Aaaaand just over 12 Volts showing on the voltmeter, %&*!*#, not charging enough, so get the multimeter out just to verify and yep 12.4 volts. Thankfully I had already planned to swap the alternator to a higher capacity. I plan on installing an electric fan at some stage and have already changed to an electric fuel pump from the mechanical one, so a bigger alternator seemed like a good idea. Sooo a few months ago I investigated the possibilites and yep I could get something that fitted in, but at an eye wateringly high price when shipped or bought in Norway, and of unknown quality. So the hunt was on for something from another car that would do and that would fit without too much frigging about. After lots of internet checking I found that one from a Mazda B200 diesel pick could fit the bill and that amazingly there was one for sale on Norway's Gumtree equivalent - Finn.no - Brand new 70A alternator for NOK600. So this was purchased earlier in the spring and was sitting on the bench waiting for when I had spare time to try fitting it, turns out that time was on the evening before the MOT.

So whip out the defect one which according to the label was from 1992 and get cracking trying to cobble together some bracketry and wiring for the new. Wasn't too bad getting it to fit in the original bracket and getting the pulley to line up using some spacers and washers etc, this is actually the time where the stash of might just come in handy one day actually comes in handy. The trouble was that the adjuster arm wasn't long enough so I bodged together two (again spares actually come in handy) just to get it on so I could measure for a new fan belt. So with a rough measurement I had to jump in the daily to drive 35 minutes to the nearest Halfords type place to get a selection of belts and a new battery cable. I didn't want to risk the original wiring between alternator and battery so opted for a direct connection, I will need to get some kind of fuse sorted for this in the very near future. So an hour and a half later back at the workshop, purchases in hand. Belt fitted and tightened, now for the wiring as obviously the original plug wasn't going to fit. Directly connected the battery to the B+ termial on the alternator, took a feed from the + side of the coil for the 'sense' connection and bodged an extension from the original plug for the ignition light. I was pretty confident it was going to work and that the belt wouldn't screech but you know how the trepidation of turning the key kind of gets overwhelming just before the moment of truth. Still you all know how this ends as an MOT was secured the very next morning, so yeah it worked, a healthy 14.2 volts showing on the multimeter, woop. Not sure of how nice it looks in the engine bay but i'm not too concerned about that, I'm looking for reliability.

So the day of the test saw me at the local DVLA equivalent - trafikkstasjon - 8am sharp to get my 'day plates' these cost about 35 quid and are valid for one day and include insurance, the grey area is that the car must be road worthy in order for this to be valid, hard to know until I've taken the MOT but details eh. I was planning on having the MOT the week before but bizzarely the trafikkstasjon was closed for holidays the previous week! Call me old fashioned but closing a public office for a week for holidays when the next nearest one is an hour drive in either direction, crazy. Add to this that our local office is only normally open 3 days a week from 8 to 2 anyway then you can see the limits to the time I have to get this done, I had to take time off work, day plates cannot be ordered online either.

Still, paper work sorted I got the car to the test centre and settled in for a long wait, to my utter delight not more than 15 minutes later with the car still standing in the car park the tester came out and handed me the keys. Pass. I stood there smiling, I didn't want to ask too many questions in case he realised he'd made a mistake and changed his mind, but yes he could confirm a pass.

This is another oddity of the Norwegian rules that since I had had the car in for a test the previous year (last August I think) when it failed on rusty front discs, it was sufficient with a re-test where they just checked the failure points visually, so he saw the new discs and gave it a pass. No test drive, no brake pedal push, nada nothing, bonkers seeing as I've had the whole front suspension and steering off since the last time they saw it last year.

For those of you super interested in the Norwegian MOT rules I can explian them too you if you'd like.

So I tootled off back to the workshop and arrived back to find that front tyre almost flat again, so bang goes the hope of a drive to work. So now it was almost 11:30 and I had only booked the morning off work, I still had to get the wheel off, get the insurance company to change my insurance from layup to road legal, get back to the trafikkstajon to re-register my car, get the wheel to a tyre fitter and get to work before 1. Bumhats. Work is going to have to wait.

Called the insurance bods so they could update the computer system, took the wheel off, chucked it in the back of the daily, drive to the tyre fitter and drop it off explaining the suspected problem, he sucked his teeth and asked me what car it was from, I said Triumph, he sucked his teeth again and looked at me like I was a lunatic. This isn't off a motorbike was his retort. Lucky I'm not a violent man otherwise I might have been tempted to push his teeth down his throat. Not his fault he's too young to remember Triumph cars and I guess they were pretty few and far between over here even when new. I left it with him.

So back at the trafikkstasjon and present my fresh MOT, not that I needed to as it's all on the interlinked snazzy computer system thingy, she checked my valid insurance and pronounced me re-registered owner. I kind of bent the rules as I already had plates ready to put on, it's a long story I can tell if anybody is interested.

Back to the tyre fitter who had a facial expression that gave nothing away, he was contented to take 15 quid off me though with the assurance that my motorbike wheel was now air tight again. Super.

The next day I got my father in law to give me a lift to the workshop so I could lob the wheel on and drive it home. All my recent test runs and trips to the test centre had been on B roads but to get home I would have to venture out on the A road with a lofty speed limit of 80km/h, I was undewhelmed and slightly disappointed with the driving experience, it should have been a happy day, but the car was just so sluggish. Other commitments got in the way but a couple of days later I had time to tinker, first though I thought i just nip up the wheel nuts, always the sensible thing to do after a few kms, right? Kind of glad I did and at the same time utterly pizzled off that I did.

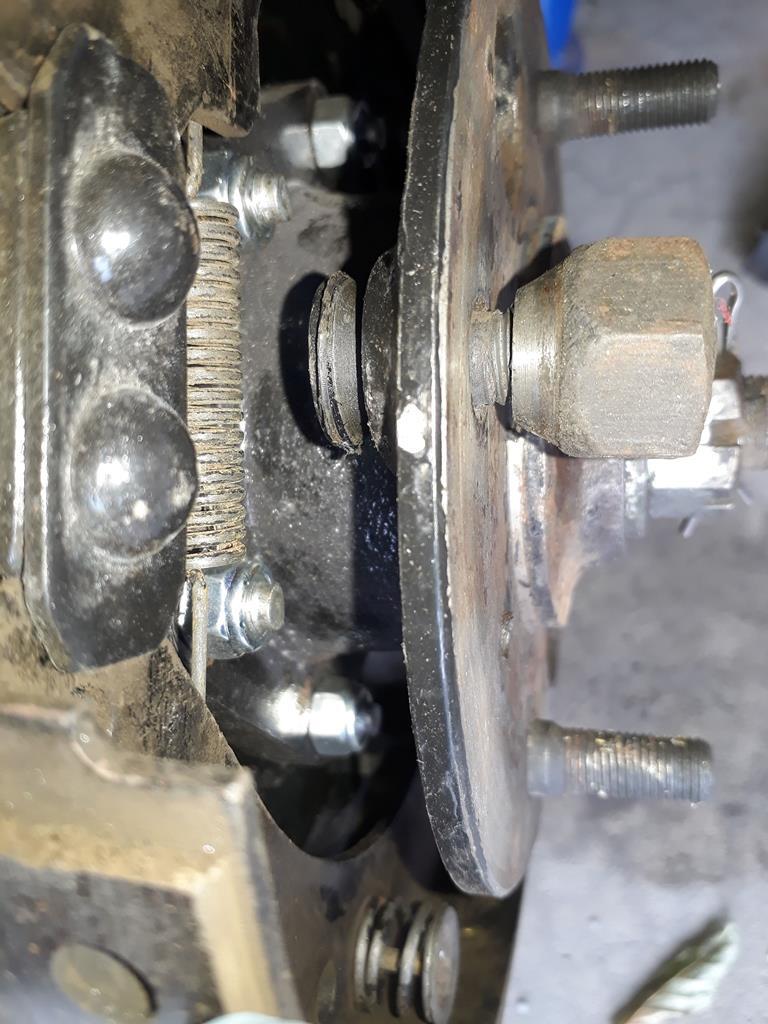

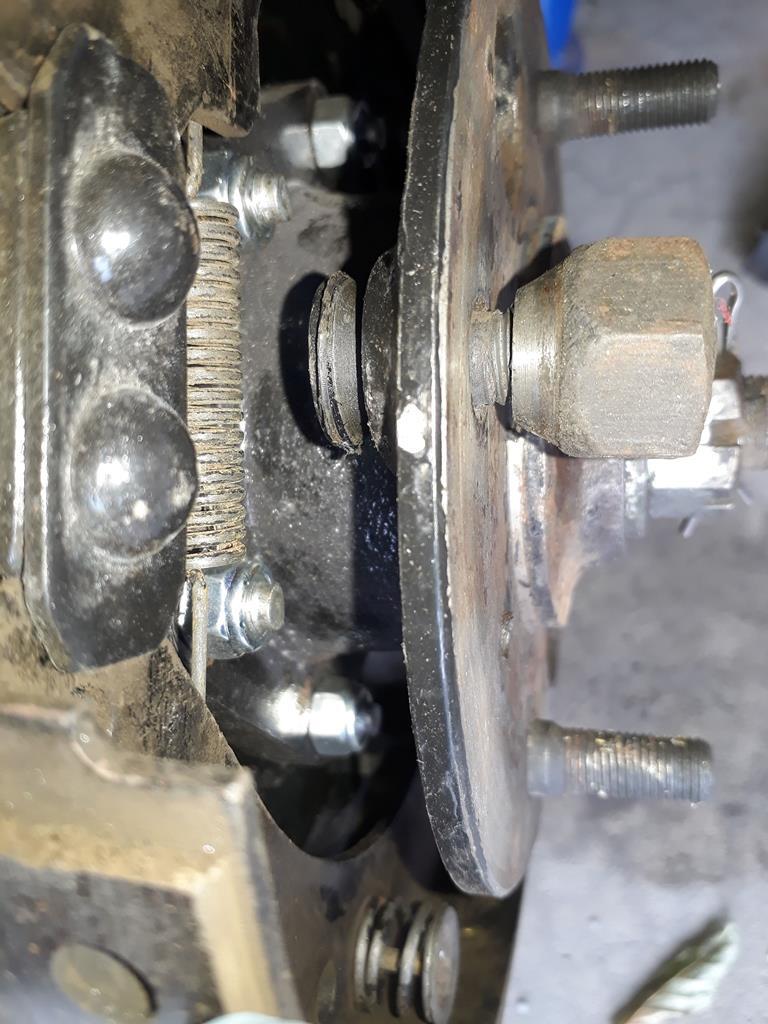

Hmm not much resistance with one of the nuts, at this point I do what all normal people do back away slowly, hoping in my heart that if I come back after tightening the remaining ones that somehow things would somehow magically be resolved, but knowing in my head that my heart has no idea about reality. I nip up the rest and venture back to the slack one, gingerly place the socket over a give it a turn. The nut falls off with the remains of the snapped wheel stud inside. %*!%¤# arses.

So it's Thursday evening and the weekend of getting the car fettled just disappeared down the tubes. Gutted. The snapped bit of the wheel stud was a bstard to get out of th nut too.

So I have a snapped wheel stud and I don't really fancy bashing it out with a hammer so fall upon the idea of using a ball joint splitter, it worked like a dream. That cheered me up no end.

Now usually I avoid ordering from Rimmers but they have a LOT of stock and their international postage is second to none, they are efficient like no small supplier can get close to and the chance of me finding a UNF wheel stud in Norway is pretty non existent. So I placed an order adding a couple of heater hoses as the ones on the car were looking a bit dubious. I squeaked in under the VAT limit too, bonus.

The website confirmed that the order was despatched on Friday 20th July, I was hoping for the parcel to arrive Tuesday or Wednesday the following week, I hadn't considered how utterly useless the Norwegian postal system can be at times, the days went by and 10, yes 10 days later, the parcel dropped into my post box.

Happy days, wheel stud pulled in to place heater, hoses swapped and we are back in business leaving just a couple of days fettling.

I have already fitted new points and condensor ordered from the Distributor Doctor in the UK so now I set the points dwell angle as specified in the manual and had a bit of a play with the timing, advancing it a fair bit more and gradually retarding until pinking was gone under load and the car now feels soooo much nicer to drive, not actually had a strobe on to see what the timing is at now but it is fairly academic these days anyway due to the different petrol specifications being used in modern fuels, I find it's better to set the timing by feel and ear than anything else.

So up to date and very happy to have it back on the road, still plenty on the wish list for future improvements, the first priority probably to be the fitment of Alfa Romeo 159 seats. As much as I like the retroness of the front squishy seats, unfortunately they, together with no PAS and a much heavier clutch than modern cars are not a good mix for my ageing back, I find it pretty uncomfortable after an hour or so in the drivers seat.

So, wish list reads, in no particular order:

. new seats

. tidy the alternator installation

. rear seatbelts

. change the exhaust manifold to a TR6 one (alreday bought)

. Chris Witor semi sport exhaust

. move the battery to the boot.

. rebuild my spare 2.5 engine

. overdrive gearbox

. general consmetics refit of chrome trim etc.

. radio, maybe.