v8

Part of things

Posts: 312

|

|

Aug 13, 2015 19:40:08 GMT

|

|

Thanks for the reply.

It's such a steep learning curve - I would hate to start off with an overly difficult program if easier ones are available...

|

| |

|

|

|

|

|

|

|

|

|

|

I have heard good things about Mach 3 for hobby use. No personal experience with it, but a lot of the guys that build the hobby type cnc machines use it. And it's fairly cheap. Think you can get a free trail download as well, so might be worth looking into? Delcam is fairly similar to Mastercam. There is another one, I think locally developed, incam maybe? Might be worth looking into as well. Just depends on your budget and what you want to use it for. I like Mastercam as I can use it for all my drawing, and then write programs straight from there for either the mill or the lathe. Also have the wire cutting version as well. Pity I no longer have access to that. Previous company had one, cut my teeth on wire edm there.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

|

I must be getting old, state of the art when I did my apprenticeship it was paper Ticka? tape and IBM punch cards, even now, I was running a mill the other day which can only be manually programmed, then the Manager mentioned he did his apprenticeship on this machine 40 years ago, It has its own system that fails to follow any logic, I would love a home program that I could play with, one that makes sense!!

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

Aug 14, 2015 17:29:39 GMT

|

I must be getting old, state of the art when I did my apprenticeship it was paper Ticka? tape and IBM punch cards, even now, I was running a mill the other day which can only be manually programmed, then the Manager mentioned he did his apprenticeship on this machine 40 years ago, It has its own system that fails to follow any logic, I would love a home program that I could play with, one that makes sense!! Ticker tape was just being phased out when I started. We had an Agie wire edm machine that still had that option. Was a brilliant machine, accurate like hell. Had an interface made for it so it could be run off Mastercam. Boss bought two new edm machines in the 12 years I was with him, but that Agie never got sold. He just didn't have the heart ! As an aside, if you ever find yourself in Vienna, there is a museum of technology just around the corner from Schonnbrunn castle. Incredible place. Cars on the fourth floor. Helicopters and planes on the fifth floor. Heavily sponsored by Siemens, ABB and Otto Bock. They have the latest robots etc all working, but they have an incredible section on machine tools. The whole history of cnc, including ticker tape! Well worth a day there. Incredible what they have. |

| |

|

|

|

|

|

Aug 16, 2015 14:35:10 GMT

|

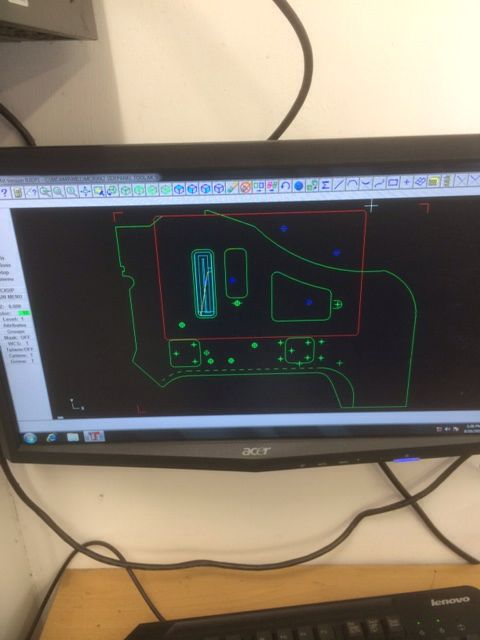

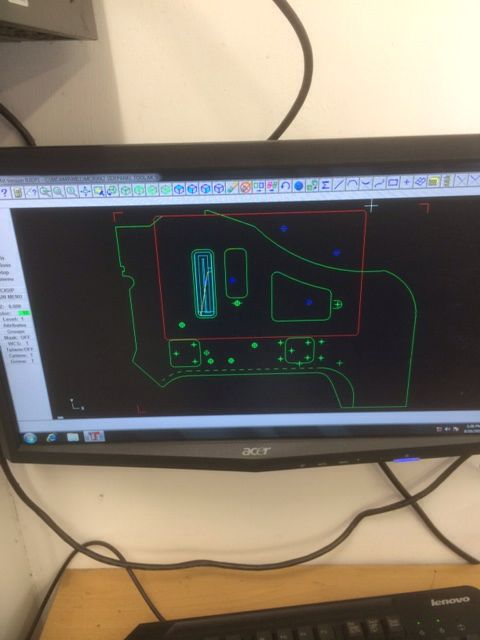

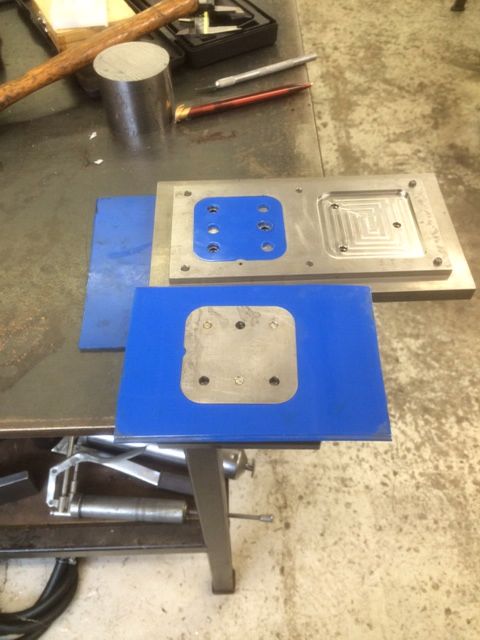

So,the weekend was upon us. Time to get going. Having spent the last week and a half converting big lumps of acetal into useful things and filling more than plenty dustbins full of plastic maggots, I was looking at addressing my tinworm problem again. Plan was to start making the tools for the side panels. So, it was up with the drawings...  Plan was to see if I could cheat abit with the press tool for this. Actually, a lot. I didn't want to make a conventional tool to press the shapes into the blank. Spurred on by my messing about with the urethane for the last tool , I decided on the same sort of approach. However, I would need two tools as the panels are handed. Or would I ? A fiendish plan was hatched. Needed to clean all the plastic maggots out the cnc mill before I started. So, off I went. Took the doors off, filled two dustbins up. Moved the bed of the machine right forward. Grabbed my specially made long ally handled broom and was about to start moving maggots forward. Stuck my hand in, aiming the broom at the back left hand corner. Had forgotten to unload the carbide milling tool out the spindle. Maggots started to turn maroon. I had sprung a serious hydraulic fluid leak, having opened up my knuckle on my index finger down to the bone. |

| |

|

|

|

|

|

Aug 16, 2015 14:47:37 GMT

|

Things not going to plan. Washed wound out. This needs stitches. curse word. Locked up and off to A and E. Now the fun starts. Finger throbbing like curse word. Traffic going nowhere slowly. At this rate my finger will fall off before I get near the hospital. Remembered the Vulcan was flying over the Headcorn air show, hence the traffic. Time for plan b. Made it to the hardware shop. Bought some gardening gloves and a bottle of superglue. Got back and glued my knuckle back together. Cut the middle finger off the glove. Put plasters over the superglue and the cut off glove finger over the whole lot. Job done. Back to work then, hahaha. Disposed of the rest of the plastic maggots that now resembled the remains of a chicken tikka masala. Had liberated a bit of 12mm plate from the skip last week.  Started milling the shapes into it. Actually, right through it.  Called it a day. Went home and anesthetised my finger by drinking copious amounts of beer, all for purely medicinal reasons .... |

| |

|

|

|

|

|

Aug 16, 2015 14:54:50 GMT

|

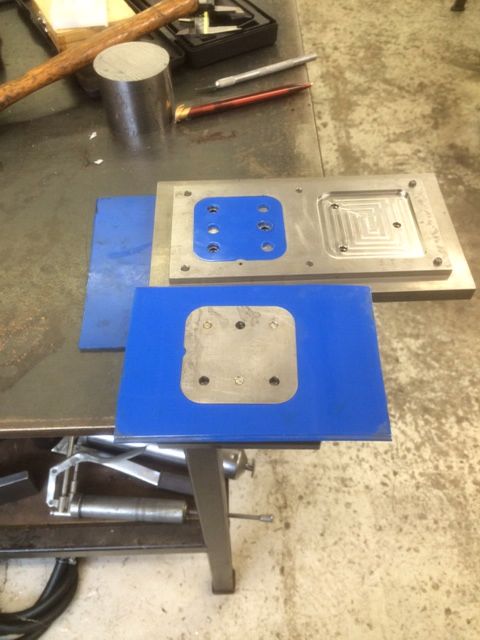

Sunday morning. No blood in the bed and finger still attached. Good start. Took plasters off. Think I need an honorary doctorate in stitch less wound closure...not infected either. Things looking up. Back to work. Finished milling the die plate out. Drilled a couple of holes in it. Chucked the whole lot in the press.  Very positive start  Need to make a spacer plate to go into the cavity as the plate is thicker than what I need to draw down to. But, the best bit is when I do the opposite side, I just flip the plate over. Result! |

| |

|

|

|

|

|

Aug 16, 2015 14:55:56 GMT

|

|

As a matter of interest, are the photos from today the right way up?

|

| |

|

|

|

|

|

Aug 16, 2015 16:54:58 GMT

|

|

If Carlsberg did car restoration !!

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,976

Club RR Member Number: 71

Member is Online

|

|

Aug 16, 2015 19:35:05 GMT

|

If Carlsberg did car restoration !! ^ This Mind you if carlsburg did restos I think there would be less claret |

| |

|

|

v8

Part of things

Posts: 312

|

|

Aug 16, 2015 19:49:27 GMT

|

I have heard good things about Mach 3 for hobby use. No personal experience with it, but a lot of the guys that build the hobby type cnc machines use it. And it's fairly cheap. Think you can get a free trail download as well, so might be worth looking into? Delcam is fairly similar to Mastercam. There is another one, I think locally developed, incam maybe? Might be worth looking into as well. Just depends on your budget and what you want to use it for. I like Mastercam as I can use it for all my drawing, and then write programs straight from there for either the mill or the lathe. Also have the wire cutting version as well. Pity I no longer have access to that. Previous company had one, cut my teeth on wire edm there. I need it for work, plastic injection mould tools. When I did my apprenticeship the college had a 'Moog NC' we had to program the punched tape, back in around 1985! |

| |

|

|

|

|

|

|

|

I worked for a tool and die making company in South Africa for twelve years. That's where I learnt Mastercam. It pretty much was the industry standard. Don't get me wrong, it's a brilliant program. Very versatile. It can be daunting in the beginning because it seems as if there are way too many options to ,for example, create an arc. You can be up and running fairly quickly, learning as you go. There seems to be a whole drive with people believing everything needs to be modelled in solids. Total waste of time in my opinion. Why would I want a 3d model of a washer? Lol. Mastercam gives you the option with solids, surfaces, wireframe or 2d. Once you get your head around the way it thinks, there is nothing you cannot do. We used to do a lot of plastic injection tools, mainly multi cavities for the medical field. Normally used to make a pilot tool, single cavity. Once customer was happy we would make multi cavity tools. Had a milling machine that was reputed to have been the second largest in the Southern Hemisphere , ex BMW in Rossyln. Company did bit press tools as well. I ran the big mill. Mastercam was brilliant in all aspects. Before I left we did all the aluminium diecasting tools used for the stadium lights for the football World Cup in 2010. Also did a big Canadian runner plastic injection mould for a grid used in the cooling towers of a power station. Wireframe was a very quick way of drawing the runners. Landed up making a hot runner tool using all the goodies from Mastip. Injecting in 16 different zones, the manifold was over 1500mm long! Most challenging job was a repair to a tool that weighed 13 tonnes. What was it you ask? A tool for making plastic garden chairs! I now work for a multifaceted engineering company. Do a lot of production and batch work. Still make press tools, but mainly for our own use. Make a fair amount of stuff for a collection that restores WW2 tanks. A lot of my stuff is in a series on Quest,on a Thursday night, think it's called Military dealers? Anyway, Mastercam does it all for me. I will stick to what I know!  Did that for a customer from a old photo! It's the grease cap on the wheel ! |

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

|

Ahhh, thats interesting, Combat dealers??? When I live in Maidstone, I knew the "Twins", they lived in Bearstead, I supplied them with bits n Pieces for their rods they were building, Small world.

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

|

|

|

That's it. Nick and Phil both work for Bruce. There is a new guy there also , Freddie ,and his son is doing an apprenticeship there.

|

| |

|

|

|

|

|

Aug 23, 2015 13:06:27 GMT

|

Good weekend with a bit of Oldskool milling thrown in for good measure.    Can. You see what it is yet? Nope, neither can I , hahaha |

| |

|

|

|

|

|

Aug 23, 2015 13:12:03 GMT

|

Back onto the cnc for some profiles  Bit of urethane between the halves and into the press  Result  Another piece of the puzzle done  So, all in all a good day. The side panels are slowly taking shape.....  And in the next highly unthrilling instalment of one man and his rust.... What to do with a 20mm thick lump of steel......  |

| |

|

|

|

|

|

|

|

|

This is fun! Keep it up. As you were.

|

| |

|

|

dikkehemaworst

Club Retro Rides Member

Posts: 1,638

Club RR Member Number: 16

|

|

Aug 27, 2015 10:22:41 GMT

|

|

What to do with a 20mm sheet of steel?

You probably mill it into a holidaycabin or a shopping mall.. :-)

epic work btw

|

| |

|

|

|

|

|

Aug 28, 2015 18:31:59 GMT

|

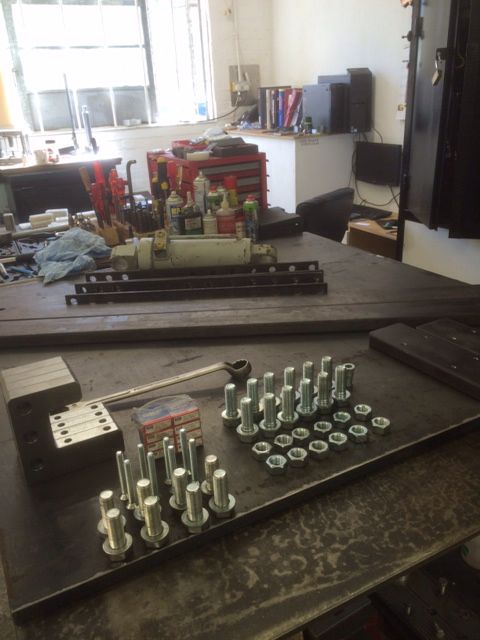

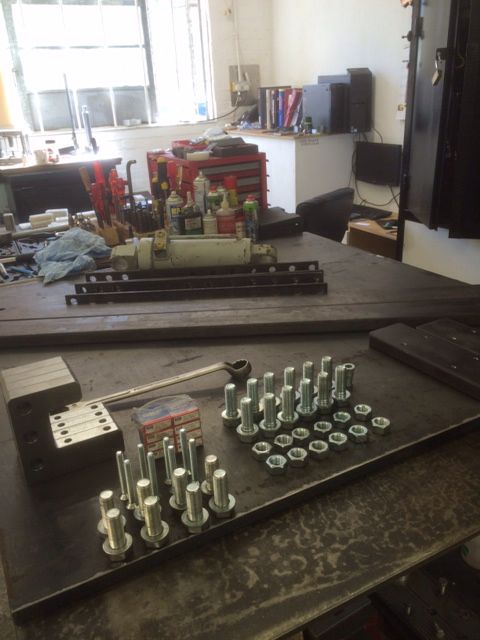

So, this is what I did with the 20mm plate....  Totally inspiring, hahaha In other news I dug out my newly fabricated man sized meccano set  |

| |

|

|

|

|

|

Aug 28, 2015 19:25:02 GMT

|

Totally uninspired, I started bolting it to get her   Think you can all figure it out by now.....  |

| |

|

|