|

|

|

|

|

One corner piece useable as it is. Other one has issues  But main thing is, they haven't been repaired so I can see what shape they should have. I have an idea for these. Something I hope to try out in the next month or two.... |

| |

|

|

|

|

|

|

|

May 25, 2015 15:50:02 GMT

|

So,we are now all update. Went in this morning and did a bit of turning Found some off cuts from a job that I did about a year ago ,lying under my bench  Faced on side and drilled a hole  Finished the other side.  Two needed a bit of a profile to clear  That done I painted the rear spit mount  Problem solved.  Can now turn the car upside down with my pinkie finger..  I realised my mistake with the spit and the position of the pivots. I had used a measuring stick graduated in millimetres when I marked out the pivot points. I was 25000g out of centre. Tell the kids of today that distance is measured in grams , and they would never believe you... |

| |

|

|

|

|

|

May 25, 2015 16:26:31 GMT

|

So. Spit finished. Result. Packed the car back in the garage and turned my attention to the shrinker stretcher stands. I had originally designed the outriggers where they bolt onto to support the shrinker only. It was going to be hand operated. Having tried it,I didn't like the idea. It felt arkward. So, redesigned them for foot operated use. Had been on the back burner for awhile , so decided to crack on for a couple of hours today. Had made the bearing seat inserts awhile back but needed to drill a 44mmhole through the leg.  Welded the inserts in  Assembled again so I could work out the dimensions of some of the bits I need to make. Will make them up later this week.   |

| |

Last Edit: May 25, 2015 16:29:24 GMT by Deleted: Double post of picture. iPad adamant its staying like that. Johnny nil, iPad one....

|

|

actionslaxx

Part of things

a message to you rudy

a message to you rudy

Posts: 74

|

|

May 25, 2015 17:06:54 GMT

|

|

This is something else, you could always build a terminator to drive the Rx2 and you probably could.

|

| |

|

|

craig1010cc

Club Retro Rides Member

Posts: 2,998

Club RR Member Number: 35

|

|

May 25, 2015 17:29:51 GMT

|

Amazing story so far, will be something special by the time you're finished, along with an impressive collection of tools  |

| |

|

|

|

|

|

May 30, 2015 13:15:02 GMT

|

|

|

| |

|

|

|

|

|

May 30, 2015 13:27:58 GMT

|

|

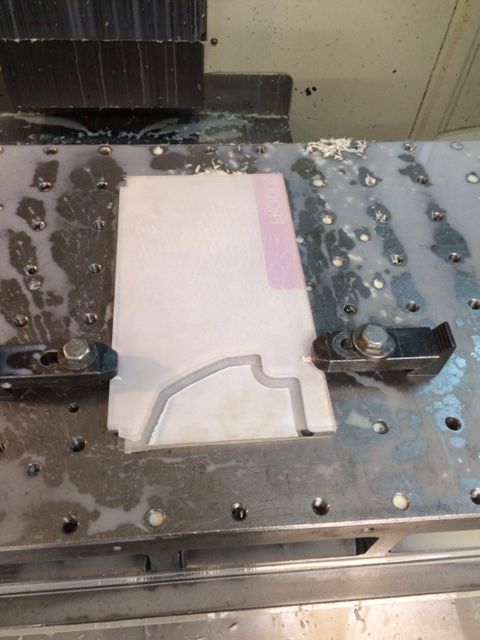

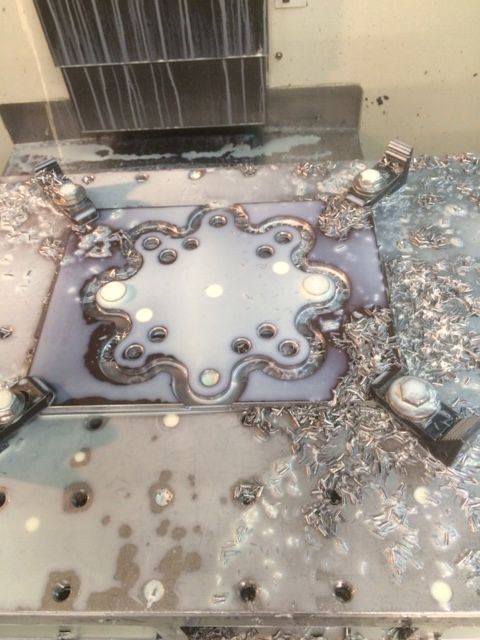

So technical! It's like panel beating without a hammer in sight!

|

| |

|

|

|

|

|

May 31, 2015 15:31:46 GMT

|

|

|

| |

|

|

|

|

|

May 31, 2015 18:10:13 GMT

|

|

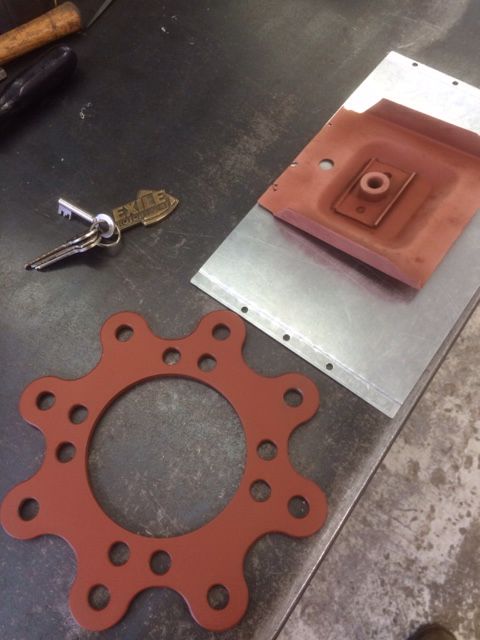

i suppose if you end up making tooling for lots of complicated areas to fix yours, you could end up in fortuitous situation to produce small batches to sell ?

|

| |

|

|

|

|

|

|

|

i suppose if you end up making tooling for lots of complicated areas to fix yours, you could end up in fortuitous situation to produce small batches to sell ? With only a handful of these cars around! There isn't any market for parts. Still quite a lot in Aus and NZ, but they don't seem to replace sills,etc. haven't got the rust problems like we do. So all press tooling etc will be scrapped when I am finished. |

| |

|

|

|

|

|

|

|

|

Bookmarked and participated so it appears in both my lists.

Amazing work, you've made tools I've never even heard of.

Great story telling too which is a vital part of build threads IMHO.

PS I could post a million threads with different smilies on each from every device available but I'd swap it in a second for your fabricating skills.

You're not just fabricating, you're fabricating tools to allow you to fabricate!

|

| |

|

|

|

|

|

|

|

nice to see hows it's done when you have all the toys  i like your spot weld drill with the stop |

| |

|

|

cap78

Part of things

Posts: 96

|

|

|

|

|

Holy curse word, one of the best and entertaining threads I've ever seen!

Fantastic work, keep going :-)

|

| |

|

|

|

|

|

|

|

|

Thanks for the kind words guys !

|

| |

|

|

|

|

|

|

|

|

Great work there mate, as a fellow ex-pat natalian, I very much enjoyed your story about the zulu junkyard king.

I can totally relate to that.

And I must say that shopping trollies are the best for moving things around, they make great engine movers and the casters are strong as a strong thing.

Good to see another 70's mazdarati being saved, I must say that I'd love to have the cnc machines that you have at your disposal

I can only dream of the things that i would bodge together with those babies.

Keep it up

|

| |

|

|

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

|

|

|

|

Square plate with holes would have done for me but I do love how you make everything look perfect, means to me that the car will be finished to teaboy oil tank or sweetpea bumper iron std |

| |

|

|

|

|

|

|

|

Eventually got this done today.  Some clever little Sugar Honey Iced Tea decided that the guillotine was the only tool we have capable of cutting square bar. £1500 later the blades have now been replaced and I could carry on with the inner sills. Drilled and deburred the holes ready for the chassis punch.  Holes polished after punching.  Into a very terminally ill press.  After much huffing and puffing but not much blowing your house down....   Press is basically worn out from a production job before my time coupled to no maintainence and dirty oil. Can now hardly pull the skin off custard. Cannot really justify spending £1000 on a new hydraulic power pack and replacing the ram. It doesn't get used that much any more, so have started looking into plan B....... |

| |

|

|

|

|

|

|

|

|

Please tell us it involves building your own new power press and dies to make up complete repro panels! The Aussies and Kiwis do use rust repair panels but it often makes sense for them to start with the best shell you kind find when it is an option.

|

| |

|

|

|

|

|

|

|

Slap a big bottle jack in it, pump the handle vigorously, and call it done? Seems like youre finding excuses not to wade in.  |

| |

|

|