|

|

|

Oct 26, 2015 16:09:52 GMT

|

Got the welding done on the Miata sill re-enforcement and slid the Vovlo over the top to see how they lined up. Good result! The Miata re-enforcement structure slips right up against the inside of the Volvo sills. This is looking inside the PS door. It was important that the Miata sill not be so high that it eliminated the Volvo picnchweld since the door seal needs to go there.  Perfect fit. Now problems running a bead down this fitment.  As much as I want to weld the two cars together permanently, I now have to move to the rear and sort out this lot. Wheel-tubs need to be merged. The gap where I ran out of Miata before reaching the back of the Volvo needs to be dealt with, and the fuel tank needs to move back and under what will be a flat deck. Might sound like a lot, but compared to the work done up front, its all pretty basic metalwork; something to keep me busy over the winter. Have also just received all the parts to build the 302 V8.  |

| |

|

|

|

|

v8

Part of things

Posts: 312

|

|

Oct 26, 2015 19:09:19 GMT

|

Keep the updates coming  What spec is the 302 going to be ? |

| |

|

|

|

|

|

Oct 26, 2015 20:15:05 GMT

|

Keep the updates coming  What spec is the 302 going to be ? Nothing too wild. The car is meant to be a lazy high torque highway cruiser, not a drag car. Going for the torque under 5000 rpm and reliability. The basic engine is a 0.030" over 302 with a set of alloy heads and an E spec hydraulic roller cam. This will be attached to an AOD gearbox. The rear end is a 8.8 out of a T-bird with a 3.73 ration and posi. Figure at about 2500 rpm I should be humming down the HWY at 75 mph and listening to the tunes with a bit of power in reserve if need be! If I get bored with this engine, I can always build a bigger warhead in the future. |

| |

|

|

|

|

|

|

|

Love it - inspired madness!  |

| |

|

|

|

|

|

|

|

Never did post a pic of the finished sill structure.  Added a couple of braces at the A and B post structure just for a bit more torsional rigidity; cause who does not like torsional rigidity in their chassis!   Course that could all use a lick of paint, and I will do so as soon as I go buy a new supply of foam brushes; I ran out. Moving to the rear, the days goal was to figure how to merge the Miata and Volvo wheel-tubs. The two nest together with about 1" of separation.  |

| |

Last Edit: Nov 2, 2015 13:55:12 GMT by bjornagn

|

|

|

|

|

|

|

The Volvo wheel-tub fails to reach the Miata deck by between 1 to 1.5" depending on where you measure the cut at the bottom  As shown already, the Miata wheel-tub is nested inside the Volvo wheel-tub with about 1" of separation. So we need to find a common denominator (or create one) where the two can join in a strength adding manner. So, what I decided to do was use a 1" by 2" rectangular tube to bridge the gap at the bottom of the wheel-tub. This will fix both issues and add the strength that I am always looking for. The Volvo was raised once again. With the Volvo wheel-well out of the way the rectangular tube was fitted and placed against the Miata wheel-tub and a cut was made along the top.  So now the rectangular tube can get welded to the Miata chassis, and what is left of the Miata wheel-tub can get welded to the rectangular tube. (note that the tube still has to be formed around the front of the Miata wheel-well stub).  When the Volvo is next lowered, the Volvo wheel-tub should nestle right up to the inboard side of the rectangular tube. Since the tube is sitting right on top of the Miata chassis, it will also bridge the gap between the bottom cut on the Volvo wheel-tub to the Miata deck. The resulting box structure should be plenty strong and actually add strength to this area. |

| |

Last Edit: Nov 2, 2015 15:42:20 GMT by bjornagn

|

|

|

|

|

|

|

|

I almost passed on this because I'm not a huge fan of the Volvo shape... I'm pleased I found it though, amazing skills and lateral thinking make this a thread to watch, keep the update coming please.

|

| |

|

|

|

|

|

|

|

I'm not one for commenting much, but I love this, and I'm another one who will steal the torch through the tube idea  |

| |

|

|

|

|

|

|

|

Feeling kind of lazy. Picked up the bits to assemble the engine and painted the new sill structure. Had a beer and called it a night.   |

| |

|

|

|

|

|

|

|

|

Hi, great work. Up to now I made several restoration but I want to try a swap next. The MX5 swap could be a good option vor a MGB GT, Opel GT or Alfa Giulia GT (Bertone), without V8 and base of the MKIII MX5 a Bertone could be a fast and reliable everyday car.

Other options for my could be a Jaguar MKII on a Mercedes C202/203 or a Jaguar XJC on a shortende X308 XJR chassis?

Thank you for share! Is this your work or are you a enthusiast like me ?

Best PAgodino

|

| |

|

|

|

|

|

|

|

Hi, great work. Up to now I made several restoration but I want to try a swap next. The MX5 swap could be a good option vor a MGB GT, Opel GT or Alfa Giulia GT (Bertone), without V8 and base of the MKIII MX5 a Bertone could be a fast and reliable everyday car. Other options for my could be a Jaguar MKII on a Mercedes C202/203 or a Jaguar XJC on a shortende X308 XJR chassis? Thank you for share! Is this your work or are you a enthusiast like me ? Best PAgodino I am flattered that you would think I could do this as a job! Thank you for the ego boost. I am just somebody who is figuring this out as he goes along and having fun doing so. Since starting, I have looked at other cars that might be good candidates. The key is to match the wheelbases and track width. I had to do a lot of work because of the 7" longer wheelbase on the Volvo. An MGB would be a much easier project with the 7" wider track on the Miata being the challenge at some point. The thin with the MGB is that you would be making a less capable Miata, so why not just buy and drive a Miata (they are great little cars). |

| |

|

|

|

|

|

|

|

|

Neat and very strong work on the sills and wheel arches! Great progress.

|

| |

|

|

|

|

|

Nov 10, 2015 14:46:20 GMT

|

The rectangular filler piece is all welded in. Works a charm. When the shell goes on permanent (soon I thingk) it will get a seam weld along the bottom of the Volvo wheel-well and a re-enforcing plate in the circular depression.  Welded to the remainder of the Miata wheel-well and spot welded from underneath. Leaves the small bit at the front to deal with.  Not very inspiring photos I admit, but they are a milestone in the project towards making this a one piece car rather than two separate cars. If all goes according to plan, this should become a one piece car and on its wheel by the new-year. It will then officially become the Molvo! |

| |

Last Edit: Nov 10, 2015 14:50:40 GMT by bjornagn

|

|

fer4l

Posted a lot

Testing

Testing

Posts: 1,497

Club RR Member Number: 73

|

|

Nov 10, 2015 22:52:59 GMT

|

Marvellous metal milestones mean much Molvo Mojo!  |

| |

|

|

|

|

|

|

|

Marvellous metal milestones mean much Molvo Mojo!  Brought to you by the letter...   |

| |

|

|

|

|

|

Nov 11, 2015 18:16:40 GMT

|

Love the name "mulvo"....sounds like something from that famous Seinfeld episode......"Mulva?"  JP |

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

Nov 20, 2015 11:39:58 GMT

|

Was not going to post this cause its not very inspiring or difficult mtal work, but it is progress. Task for the day was to close off the gap behind the Volvo rear wheel tub and the Miata chassis. This also pics up the remains of the Volvo frame. Here is the bit we speak of as seen on the PS.In order to raise and lower the Volvo tub, the flange on the edge of the Miata frame has been hammered up 90 degrees. Once I flatten that to install these pieces, things will be permanent.  As seen from the side so you can see the gap that needs filling.  And the panel in place on the DS of the car.   And from below. You can see that I am overlaping to the bottom of the Volvo frame-stubb just for a bit of added strength.  Like I said, not very inspiring, but progress none the less. On track to have this Frankenstein body welded solid by the the new year. |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,361

Club RR Member Number: 64

Member is Online

|

|

Nov 20, 2015 20:03:31 GMT

|

|

All progress is good progress.

Thanks for keeping us in the loop. :-)

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Nov 22, 2015 23:21:17 GMT

|

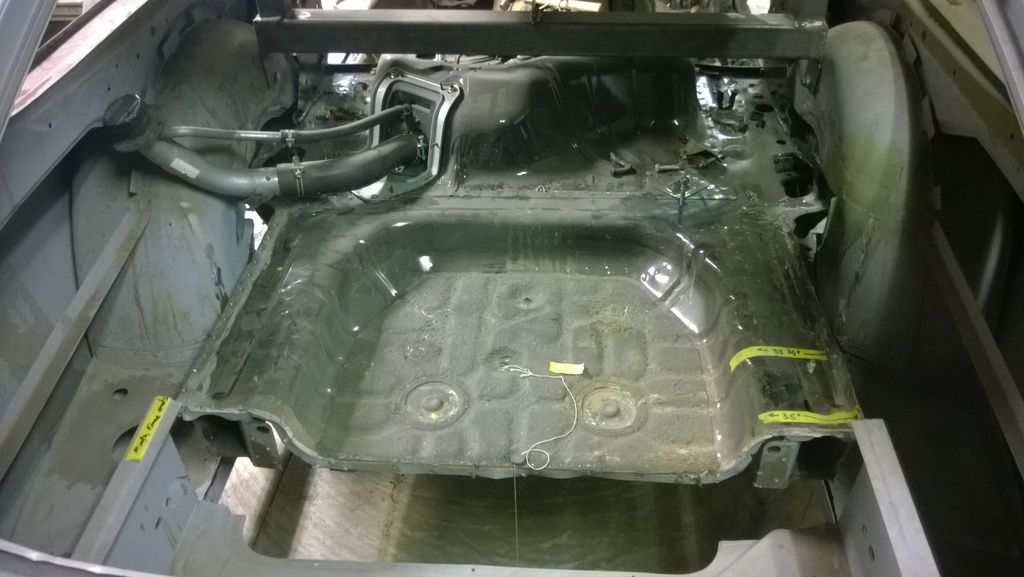

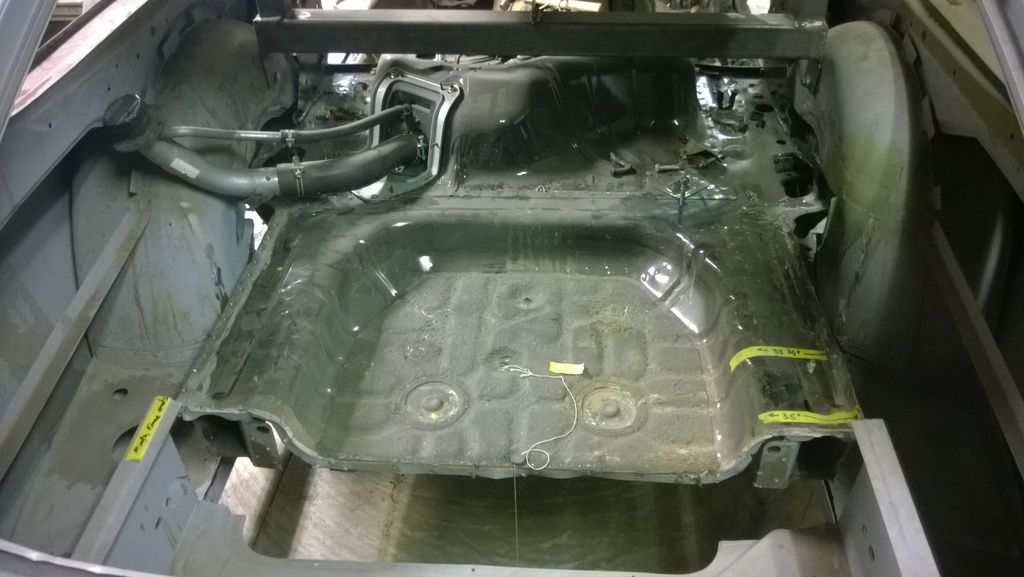

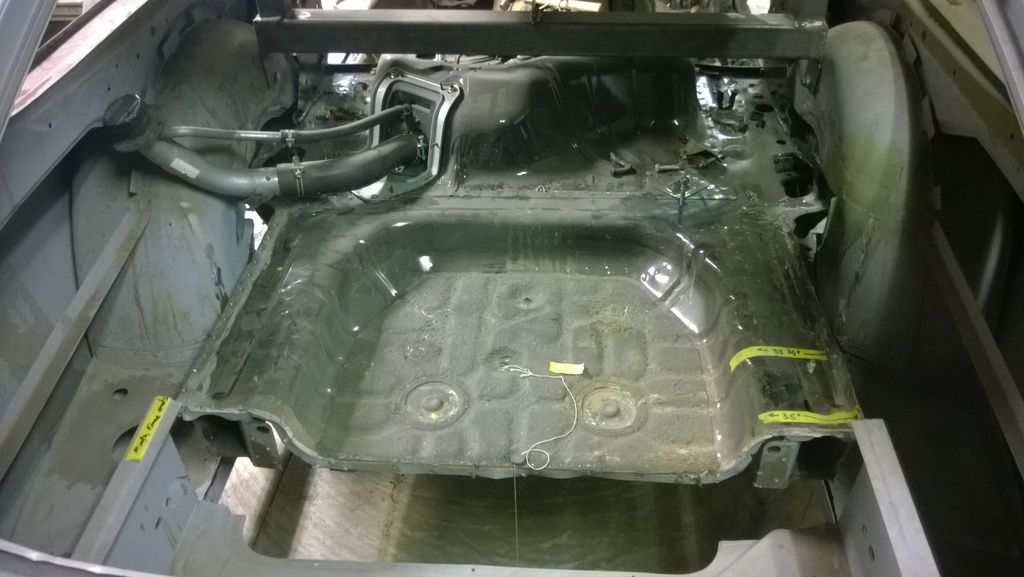

Had a great day in the shop. Not much worth taking pictures of, but a ton of detail stuff. Literally sparks were flying.  Once I cut out the trunk pan and trial fitted a Miata fuel tank in the space, I realized that was not going going to be any kind of an elegant solution. I now have two Miata fuel tanks to sell!  The rest of the session was productive but not very "photogenic" (That is another way of saying I was more into working than taking pictures) Started to clean all the metal that will be involved in the 30' for long seam that will join the two cars. Cut the motor mount pedestals off the tubular cross-member that I bought since it does not apply to my application Tidied-up and painted the cowl area where the two cars join. there was a lot of ugly rough cut tin. Did some rear frame rail repairs where I got carried away cutting the Volvo out of the Volvo. Picked up the pistons for the engine Got the engine block masked off and painted. All in all, a great day in the shop. |

| |

|

|

|

|

|

|

|

And then they became one! The sex swing is no longer required and the vice-grip in the picture is not what is holding the two together. Welded Bliss took place today!  |

| |

|

|