Bloody hell time flies. I'd better do an update.

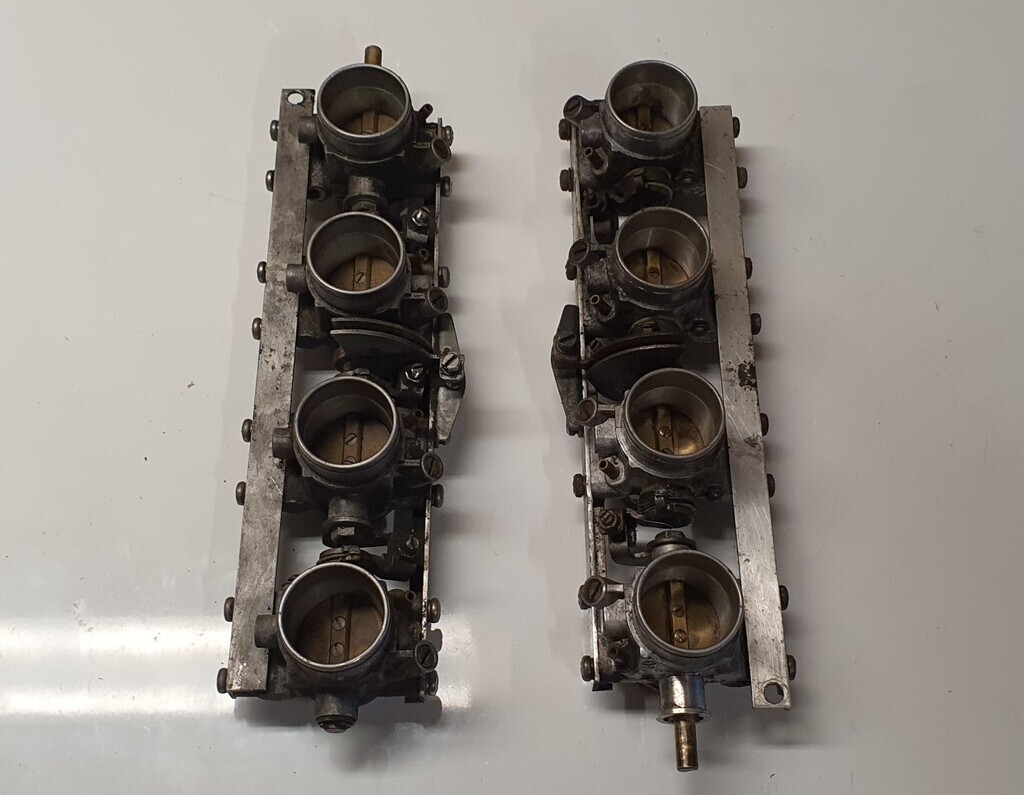

That noise. I took the throttle body off again and taped up the various superfluous holes..

Went for a drive and the sound was almost completely gone. Just a hint at certain load points under very light throttle openings. So it was indeed created by air passing over the holes - much like blowing across the top of a beer bottle.

Took it off again and filled the holes with JB weld epoxy..

I was now left with one remaining outlet that feeds air from the IACV into the throttle body. This one is the cause of the occasional 'hoot' sound at low throttle openings, higher load. Possibly the sharp edges could be transitioned out to curves which might help.

Its not enough to bother me though, especially as I now know what's making the sound. Just happy I don't have a vacuum leak.

Onto more fun jobs. The custom dash instrument cluster I want to make. Ages ago I'd got these instruments from a V6 engined Mitsi Pajero. Electronic speedo head, with analogue odometer. Very similar to the Toyota items of the mid to late 90s that I had used in my Viva V6.

I took them out...

Carefully popped the needles off using the two teaspoon method...

.jpg)

Knocked the internals down in size including removal of trip meter part..

.jpg)

.jpg)

Machined up some barrels from alloy to suit ...

..as well as some rings for spacing the gauge faces away from the acrylic fronts I'd cut out.

The needles were cut shoorter and the gauge faces cut down in diameter. Once tested and calibrated I'll make now faces with a more suitable looking classic font and style. I assembled them and stuck them onto a makeshift shelf on the dash for testing...

I then machined up an adaptor with the required m20 thread to suit the Subaru transmission...

Screws in here...

So a Toyota electronic (hall) speedo sensor can screw on top..

Went for a drive. The Rev counter works fine straight off and matches the rev counter readout on the tuning program.

The speedo reading is much closer than I was expecting considering I don't know what the gearing is on the transmission speedo output. The speedo reads about 10 percent out but does progressively go further awry as it gets closer to 100kph. When we next have a chance on a long smooth road my intentions will be to mark the speedo face using a GPS speedo as a guide for accurate speed (the Imps original strip speedo is terrible, wobbly and not accurate at all)

But none of this will happen for a little while because the clutch slave cylinder I thought I'd repaired decided to give up and make a puddle at the local fruit stall yard. We had been in town shopping and I could feel the bite point getting lower until the gears started getting very hard to select. Luckily where it finally gave up was only a few kms from home. I started the car in gear and managed to get home. This then happened that evening...

So it was time to swap back in the Datsun engine for a short while. I have clocked up 680kms on the flat six so its probably a good time to pop the sump off, check the oil pump chains have settled in nicely etc. There's a couple of spots between seams that weep oil so I'll clean them up and re-seal. It actually barely leaves a drip though and the transmission is completely leak free.

So the Honda is now out and sitting on the engine wheely stand 2000 TM. I made notes of all the various stages of removal, accounting for time spent and detailing anything that could be improved or tidied up. I'll re-write the notes in order so avoiding needless hoist ups and downs just to undo one bolt etc etc.

As it was it took just 2 hours to remove the whole Honda engine/transmission/exhaust/gearstick/cooling bits.

I then had to adapt a few bits for easier swaps such as wiring up the Datsun loom (all 5 wires..) to suit the plug that also serves the Hondas temp/oilsensor and alternator etc. The wiring is now plug and play. The axles also have to be swapped which is easy.

Before I plonked the Datsun back in place I really wanted to weigh it. I popped over to the farm across the road and nabbed our engine hoist back from their shed.

Removed the Imp transmission and then carefully lowered the engine onto the scales...

105kg. You chunky little monkey. Granted that is with everything in place inc clutch and exhaust headers. Google reckons a bare A12 engine is circa 80kgs but I was never sure. Now I know exactly what it weighs. I weighed the Datsun cross member, starter motor, exhaust box and even the stock gear shifter arrangement. Anything that was different to the Honda setup. I also weighed the stock Imp transmission.

I noted all the weights down in my Imp notebook and consulted the weights I'd put down for the Honda engine and scooby box.

The Datsun engine and imp box setup inc its specific driveshafts, exhaust system and gearshift setup comes in at 156kg

The Honda and scooby box with its modified CV driveshafts, exhaust and modified gearshift tips the scales at 170kg

I was quite pleasantly surprised at this and it does tie in well with the weight I'd got when I recently had weighed the car at the local weigh station where it was about 40kg more than when I first got the imp on the road over 5 years ago. Allowing for errors/weighbridge accuracy and the heavier Recaro seats I have added it looks pretty legit.

Happy with that I plonked the Datsun back in place, a process that went smoothly. I ran the low pressure carb fuel pump up front into the efi return line to the carb. My original Datsun coolant hoses still worked perfectly with the stainless pipes exiting the rear bulkhead that I'd modified to suit the Hondas EWP setup.

Swap a couple of wires on the fuse box, remove the efi fuses and turned the key. The Datsun started first turn of the key and settled down to a smooth idle. It actually sounded really neat.

I checked for leaks, refitted the engine cover on the rear parcel shelf and took it for a hoon.

God it feels slow and its so quiet. But its bloody lovely though. The gearshift is so sweet. Lighter than the Scooby box (although I have some ideas on how to improve its action)

So that's that. Back into its little garage for now. I need to get some new tyres and then get a fresh warrant of fitness sticker. I'd forgotten to mention earlier that I had taken it out to show the local retired certifier who is leaving his day job and will be getting back in certifications. He loves it and thinks its a very neat transplant. I've run through a few bits that I know I have to add or change to pass the cert and hopefully some time next year it'll be first on his list. Fingers crossed.

Good little Dastun...

Back into its home..

.jpg)

.jpg)

.jpg)