|

|

|

Apr 30, 2021 22:16:27 GMT

|

|

I love back yard garage builder project like this.

I hope I didn't offend you by saying this. it is a compliment!

Is this car going to be road legal?

I think taking this car to MOT will be fun!

I love the way you say a small nimble car. This is why I love classic Minis.

They are small and fitting a modern engine in will make old car usable in modern day.

I would love to come and see how you make some of your body panels.

Do you think you can show us more in detail? may be you can do Youtube video for us to see?

|

| |

Building roof chopped, screen raked '68 Mini with G13B 1.3 16v Gti engine with LSD, Yamaha R1 carbs. As well as mk1 Suzuki Swift Gti AWD with a turbo.

Drives PHEV Outlander but wishing my mk1 Swift Gti or mk2 CRX Vt were still with me!

|

|

|

|

|

|

|

|

|

I love back yard garage builder project like this. I hope I didn't offend you by saying this. it is a compliment! Is this car going to be road legal? I think taking this car to MOT will be fun! I love the way you say a small nimble car. This is why I love classic Minis. They are small and fitting a modern engine in will make old car usable in modern day. I would love to come and see how you make some of your body panels. Do you think you can show us more in detail? may be you can do Youtube video for us to see? No not at all. That's what I'm doing, working in my shed along I suspect with countless others doing what they enjoy. And I'll be pleased to see anyone who fancies popping in to see what I'm up to. It is my intention for the car to be road legal by following the DVLA Radically altered vehicle route which allows rebodying providing it qualifies for the minimum 8 points to retain the identity of the donor. If that fails I'll have it SVAd as a new car with a current registration. I can buy a brand new crate engine and have a new rear axle which will not be one from a Kitten and everything else on the build is new. As far as making panels is concerned, I am just an amateur being self-taught and not having done anything until I turned 60 so I may not be able impart too much information. I don't think I could do any videos but I can post photos of the panels as they develop from the blank sheet to blocking to being wheeled. |

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

|

Bookmarked.

Another thread where I'm torn between wanting to see the finished car and not wanting the build to end.

Dan

|

| |

|

|

|

|

|

|

|

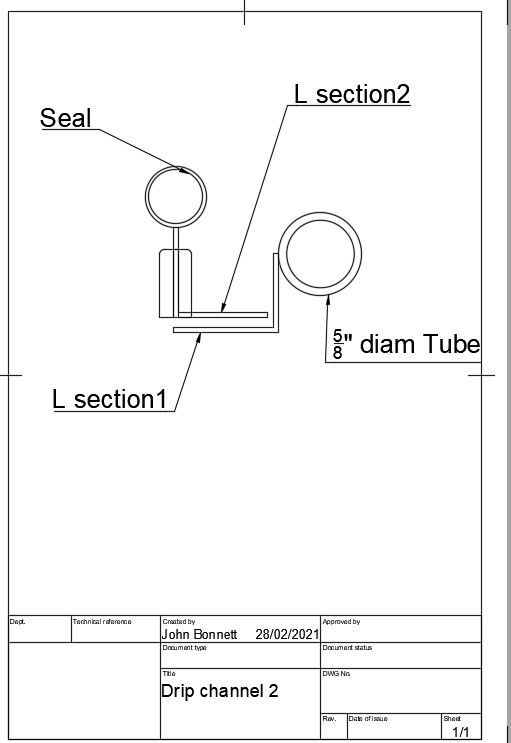

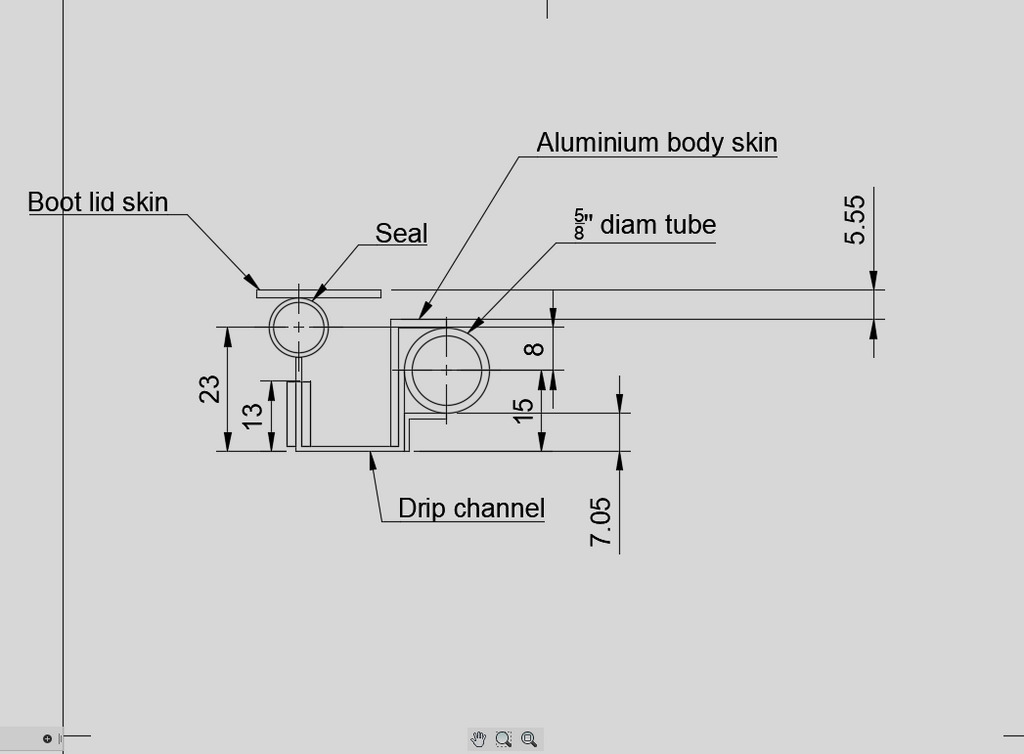

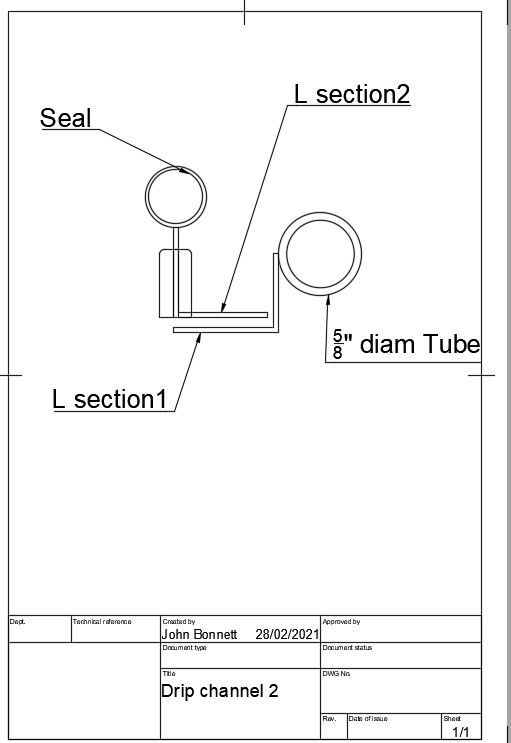

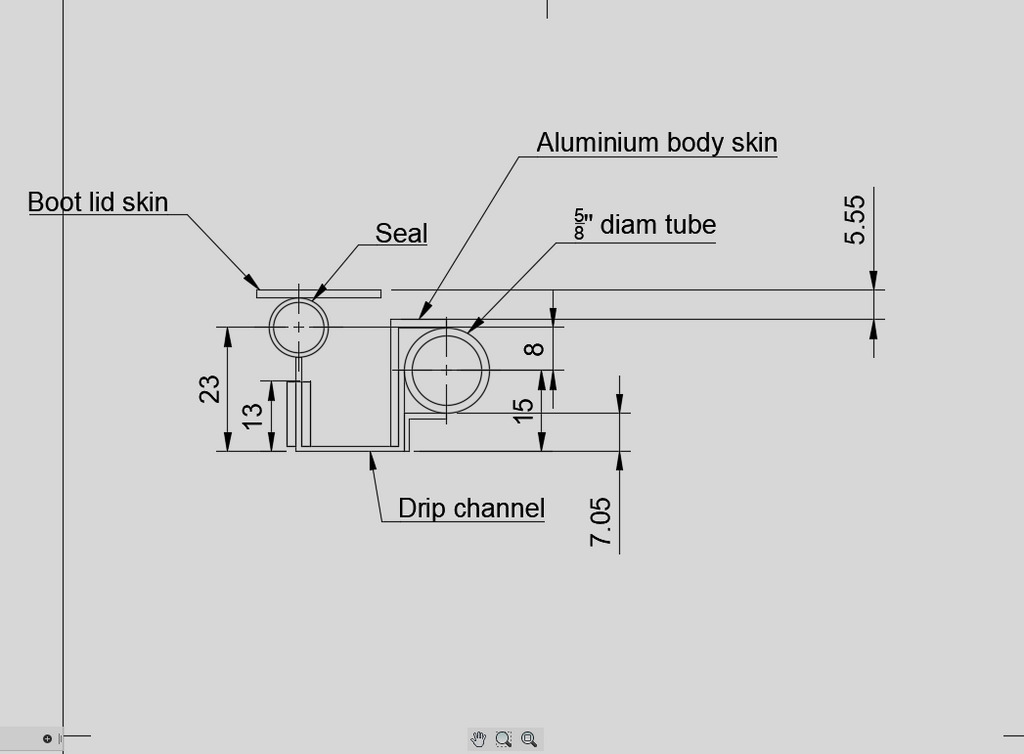

Bookmarked. Another thread where I'm torn between wanting to see the finished car and not wanting the build to end. Dan No fear of that with so much more to do. I still think of the project still being in its very early stages and many problems that will jump out along the way. The next job which i have been putting off is making the drip channel in the boot. The edge of the boot is 5/8" diameter round tube and I intend to dress the aluminium in a sharp fold around it and into the drip channel. The drip channel itself will be made from two major parts, both folded right angle section. It needs to be in two parts so that the aluminium can be attached using countersunk rivets on the vertical side. The second piece will be added after that and riveted together to make the channel. The height of the second piece is critical because that's where the seal fits and that needs to be compressed sufficiently when the boot is to make a watertight seal and also the boot lid to sit flush with the wing. I drew it up on cad and made a section and it does appear to work. So no more excuses to prevaricate so it looks like I going to have to make a start. The arrangement will be similar to the DB5.   |

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

|

Have you considered bonding the lip instead of riveting, less chance of water ingress.

Dan

|

| |

|

|

|

|

|

|

|

|

|

Well, I've made a start on the drip channel having remembered how I was going to do it. It helped finding another drawing that I did at the same time as the other one. Using the stretcher I was able to reproduce the curve in the transverse tube onto the L section strip. This will be located onto the round tube by the 7mm high L section welded to it and which is also welded onto the underside of the round tube. I hope the drawing illustrates what I'm trying to explain.   |

| |

|

|

|

|

|

|

|

|

Hi john

I'm in this to see your progress, as i don't want to miss anything

and as our other site will fall over any time now !!

steve m

|

| |

|

|

|

|

|

|

|

Hi john I'm in this to see your progress, as i don't want to miss anything and as our other site will fall over any time now !! steve m Thank you Steve for your continued interest and support which I really appreciate. That was my fear too that the site might not last for too much longer which is a huge shame given the quality of the folk that make up the community. But nothing is forever and we have to adapt. |

| |

|

|

dieselmax

Part of things

Posts: 192  Member is Online

Member is Online

|

|

|

|

I love back yard garage builder project like this. I hope I didn't offend you by saying this. it is a compliment! Is this car going to be road legal? I think taking this car to MOT will be fun! I love the way you say a small nimble car. This is why I love classic Minis. They are small and fitting a modern engine in will make old car usable in modern day. I would love to come and see how you make some of your body panels. Do you think you can show us more in detail? may be you can do Youtube video for us to see? No not at all. That's what I'm doing, working in my shed along I suspect with countless others doing what they enjoy. And I'll be pleased to see anyone who fancies popping in to see what I'm up to. It is my intention for the car to be road legal by following the DVLA Radically altered vehicle route which allows rebodying providing it qualifies for the minimum 8 points to retain the identity of the donor. If that fails I'll have it SVAd as a new car with a current registration. I can buy a brand new crate engine and have a new rear axle which will not be one from a Kitten and everything else on the build is new. As far as making panels is concerned, I am just an amateur being self-taught and not having done anything until I turned 60 so I may not be able impart too much information. I don't think I could do any videos but I can post photos of the panels as they develop from the blank sheet to blocking to being wheeled. The Radically altered points count will not change since you have a car with a separate chassis; in this case you can swap the body without loss of any points. You will loose 3 points for the engine and box swap. The suspension you might loose points, but you will keep the axles won't you? I don't know if the DVLA want a different name of the car, but essentially, there is enough reliant parts there to keep the registration I reckon. |

| |

|

|

|

|

|

|

|

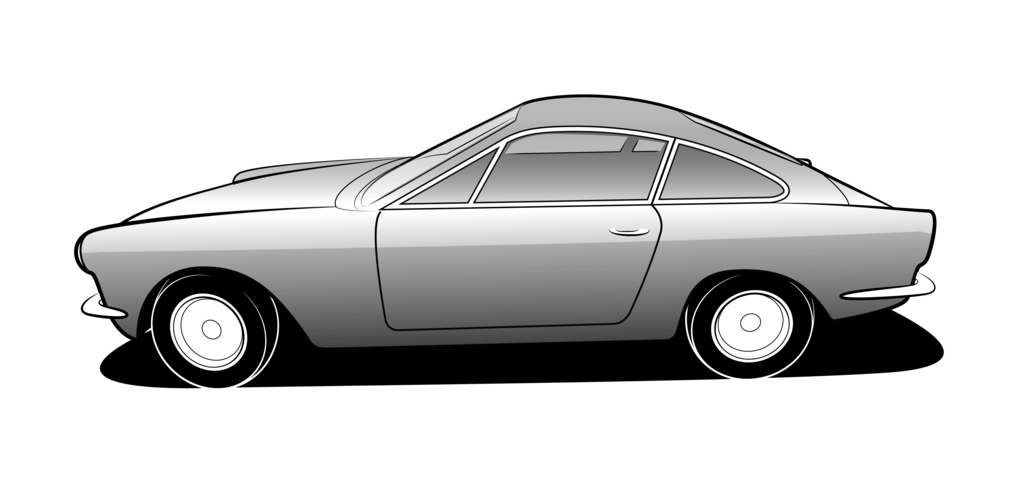

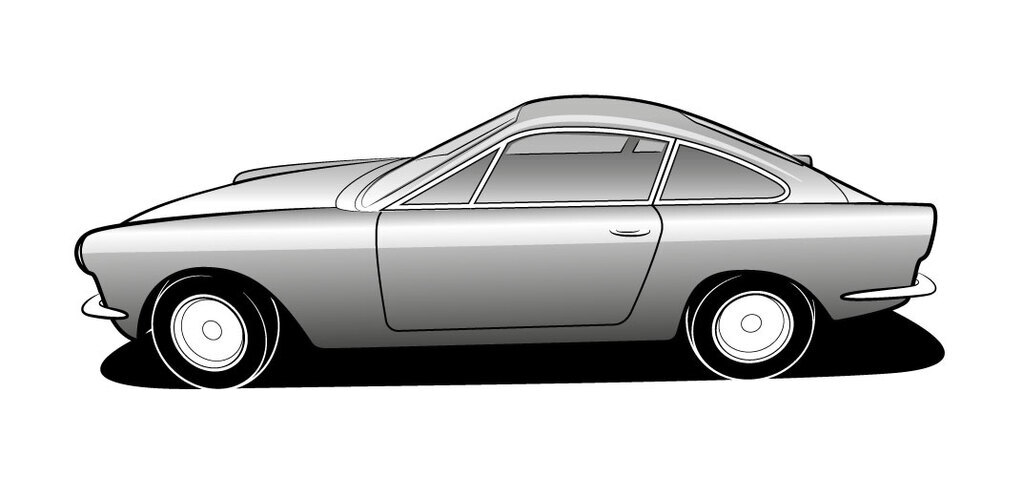

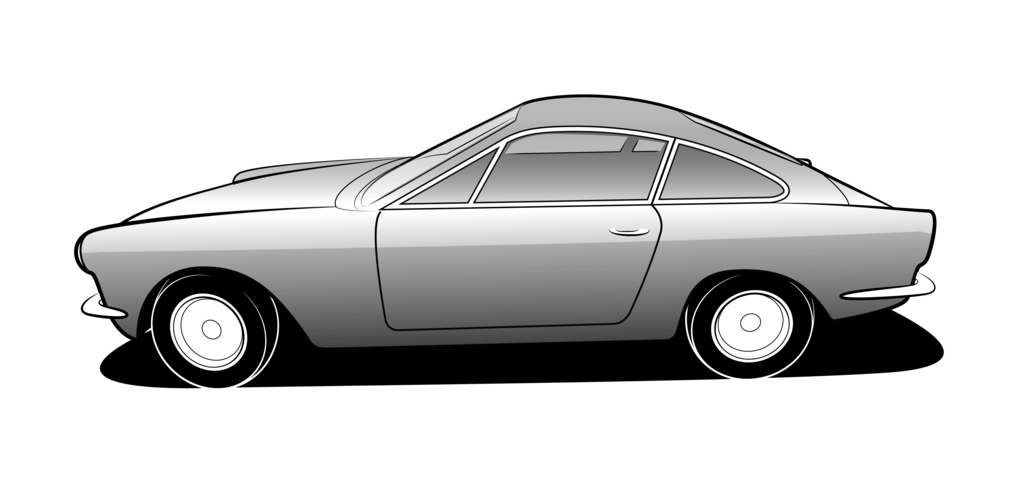

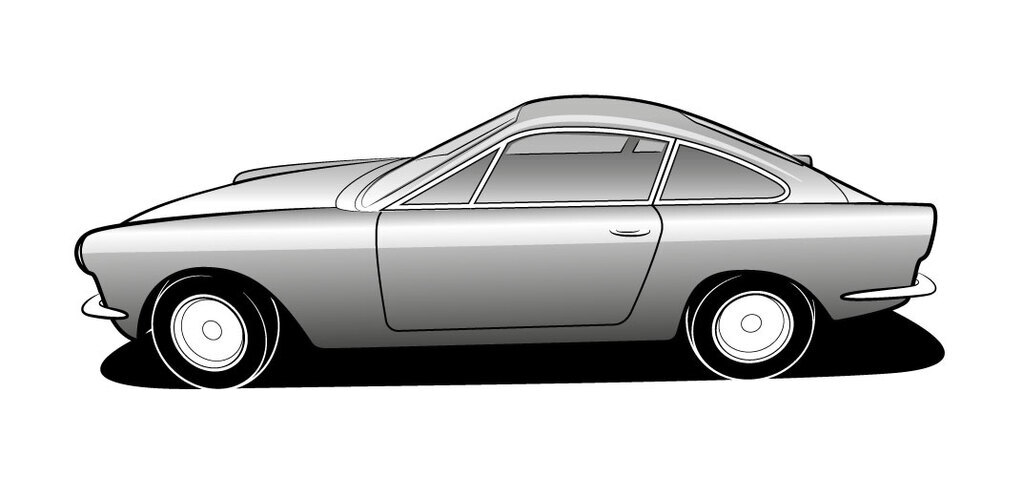

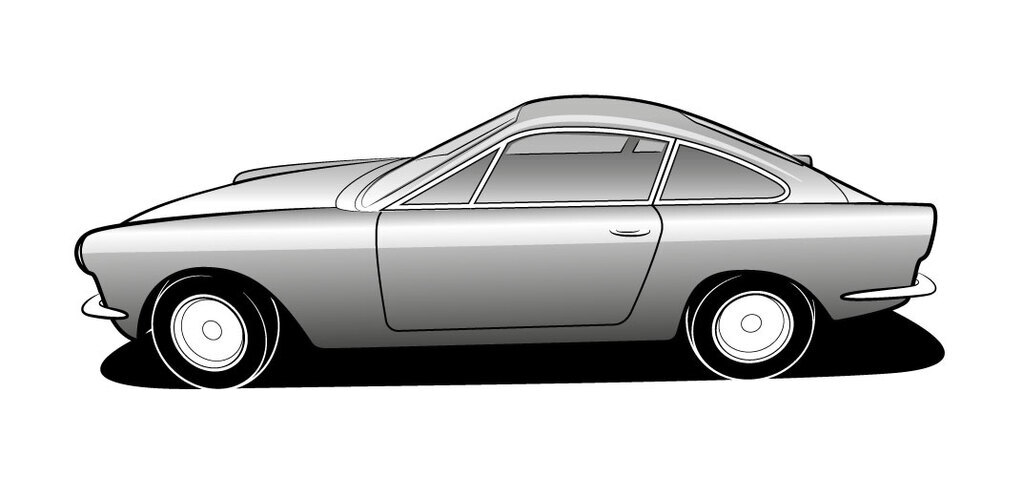

Doodling again. I might have got the wheelbase horribly wrong but that´s easily fixed.  |

| |

|

|

|

|

|

|

|

Doodling again. I might have got the wheelbase horribly wrong but that´s easily fixed.  Wheelbase is 91 inches. I really like your sketch which is so close to my concept. If it isn't too much trouble could make the waist line from the door to the top of the rear lights horizontal rather than sloping downwards? Thank you so much your help. |

| |

|

|

|

|

|

|

|

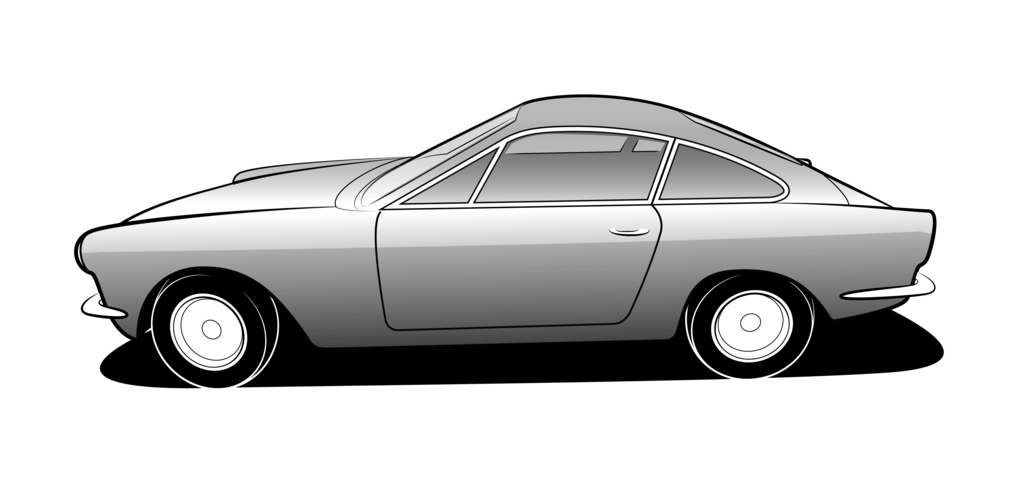

Sure, easy fix. At some point, if you can drag it outside and step back aways, to take a clear side on photo, it would help. There´s a ton of perspective on this pic. I don´t know how bothered you are, but there´s something to be said for not mixing up modern and older styles. Like bonded in screens and obvious LED lights on an otherwise vintage looking car really pokes me in the eye. I think there´s a lot to be said for sticking to an era. Though that said, the large and heavily raked screen really works on this. It all reminds me of a Glas 1300GT.  |

| |

Last Edit: May 2, 2021 17:45:20 GMT by horrido

|

|

|

|

|

|

|

In some ways metal is like pastry and can be stretched and shrunk back into itself which is something a tailor cannot do when making a suit. Tucks have to be made to lose material but with metal, like pastry it can be shrunk back into itself. Looking at the back panel which I bent on the rollers you can see when offered up onto the buck that an awful lot of material has to be lost or shrunk in order to produce the double curvature. Too much for my shrinker but very much a job for the tuck forks. The ones I have are a bit crude having been made from scrap but they work well enough. The process is the same as stump shrinking and once formed the tucks are trapped on the apex and the sides so that they cannot flatten out and then hammered.    Even with the tuck forks it needed more than one go at it to achieve the desired result. In between, the metal was smoothed using a hammer and dolly which does tend to reverse the effect of the shrinking so each time it's back a step but not back to the start!.  But we got there in the end. But further planishing needed to produce a nice curve without any highs and lows.   |

| |

|

|

|

|

|

|

|

|

Bookmarked, can't wait to see this finished

|

| |

|

|

|

|

|

|

|

|

I'd like to see more of how the shrinking works if possible please? How you hammer it down without it ending up a total mess like it would if we did it, lol.

|

| |

|

|

logicaluk

Posted a lot

Every days a school day round here

Every days a school day round here

Posts: 1,373

|

|

|

|

I'd like to see more of how the shrinking works if possible please? How you hammer it down without it ending up a total mess like it would if we did it, lol. I was thinking the same, how! Dan |

| |

|

|

|

|

|

|

|

|

Wray Shelin's video explains it far better than I can. I'd love one of his hammers!

It amused me to read your comment about "A total mess". Take a look at this

It just shows how forgiving metal is and that most of the signs that you've given it grief can be removed.

|

| |

|

|

|

|

|

|

|

Sure, easy fix. At some point, if you can drag it outside and step back aways, to take a clear side on photo, it would help. There´s a ton of perspective on this pic. I don´t know how bothered you are, but there´s something to be said for not mixing up modern and older styles. Like bonded in screens and obvious LED lights on an otherwise vintage looking car really pokes me in the eye. I think there´s a lot to be said for sticking to an era. Though that said, the large and heavily raked screen really works on this. It all reminds me of a Glas 1300GT.  I'm really grateful to you for drawing up something that I have in my mind with uncanny accuracy. It is pretty much spot on and love it. There is a resemblance to the Glas, you're right and I can see 911S undertones in there. I was planning on keeping the horizontal line of the wings right through to the front but now I'm not so sure because the slight slope you've drawn to my eye looks really nice. I agree with you about trying to stick to an era rather than a hotch poch of old and new and I want to keep it to the 1960s keeping any modern stuff hidden. The DB5 is 60s and so is the Gordon Keble and I hope my car would stand up well against them for example. The steep rake of the screen might set it apart but I really like the overall effect as you have drawn it. Once it is back on its wheels I'll try to get a shot of it outside square on to the side. Meanwhile this is the only one I have when it was wheeled out to give it a taste of the outside world. Thank you once again for your help.  |

| |

|

|

|

|

|

|

|

I'm really grateful to you for drawing up something that I have in my mind with uncanny accuracy. It is pretty much spot on and love it. There is a resemblance to the Glas, you're right and I can see 911S undertones in there. I was planning on keeping the horizontal line of the wings right through to the front but now I'm not so sure because the slight slope you've drawn to my eye looks really nice. [/quote author=" johnbonnett " source="/post/2674737/thread" timestamp="1620115639"] No problem, happy to help if I can. I´d already drawn half of it anyway, so I wondered what the whole thing would look like. Loving the metalwork instruction too. Have you found large differences between working with aluminium and steel sheet? The issue with using straight lines on a car body is a strange one. I can´t say I´d given it much thought before, aside from a feeling that it´s just a bit wrong somehow. Maybe because there aren´t straight lines in nature? Car designers almost never use them and there must be a reason that goes beyond compound curves being structurally stronger. Even on cars that we tend to think of as angular (Ok, maybe excluding the Tesla Cyber truck - which is a great example of why you shouldn't!) actually have a lot of curves on them. There are good reasons for tapering the front and rear though, mostly because it´s very visually unappealing to have a heavy looking nose or tail and every square inch you add makes the problem worse. Hence the lower edge of the sills invariably being set much lower than the front or rear valances. I think you can easily avoid the "banana effect" with a straight waistline extending across below the windows. Copy from the best... Touring of Milan got it right....just added the lines to show the subtle curves that are present, if not so obvious.  |

| |

Last Edit: May 4, 2021 12:22:53 GMT by horrido

|

|