mylittletony

Posted a lot

Posts: 2,426

Club RR Member Number: 84

|

|

|

|

|

I might be jumping the gun, or teaching you to suck eggs or whatever, but a common approach is to cut the stubs off the cooker and weld on an elbow that points in a more suitable direction.

I'm fairly sure you've got that in hand already though

|

| |

|

|

|

|

Enbloc

Part of things

Posts: 399

|

|

Jan 13, 2024 17:40:13 GMT

|

I might be jumping the gun, or teaching you to suck eggs or whatever, but a common approach is to cut the stubs off the cooker and weld on an elbow that points in a more suitable direction. I'm fairly sure you've got that in hand already though Yes, but at this point in time I didn't know where the charge pipes would fall and having 90' elbows allowed me the ability to swing the outlets in an arc. |

| |

|

|

|

|

|

Jan 13, 2024 18:52:57 GMT

|

|

I'm surprised that the turbo is doing next to nothing without an intercooler. I would have expected some sort of improvement.

|

| |

|

|

jamesd1972

Club Retro Rides Member

Posts: 2,921  Club RR Member Number: 40

Club RR Member Number: 40

|

|

|

|

|

Much like for the angled tabs for support. Form and function is a winning combo.

James

|

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Jan 14, 2024 18:28:17 GMT

|

Much like for the angled tabs for support. Form and function is a winning combo. James The idea behind the angled tabs was to push the cross bars which they attach to away from being behind the core to being behind the end caps instead. This was initially done on a degree of guesstamation and in the reality the top one ended up on the upper weld line of the intercooler because the rad frame didn't extend fully to the top and the lower tabs had to be flipped around as the intercooler actually extends below the rad a fair amount. |

| |

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,961

Club RR Member Number: 174

|

|

Jan 14, 2024 19:09:07 GMT

|

|

Epic work. Will be much better now.

|

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Jan 14, 2024 19:49:15 GMT

|

I'm surprised that the turbo is doing next to nothing without an intercooler. I would have expected some sort of improvement. Not so much doing nothing but more a case of diminishing returns. Also because its all ruuning off the ECU that has number of correction tables working in the background the ECU will pull more and more ignition timing out to correct for the hotter and hotter intake charge to keep it all in a 'safe zone' and that means the power just drops off a cliff edge. |

| |

|

|

Brigsy

Part of things

Posts: 617

|

|

Jan 14, 2024 22:14:04 GMT

|

|

Epic work, much better with the intercooler.

Might have been ok without if running methanol/alcohol i.e. dragstrip use.

|

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Jan 14, 2024 23:57:09 GMT

|

Epic work. Will be much better now. Epic work, much better with the intercooler. Might have been ok without if running methanol/alcohol i.e. dragstrip use. Thanks for the feedback. I'm hoping it will go a little better with a big boy spring swapped into the wastegate.  |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

Jan 15, 2024 21:17:23 GMT

|

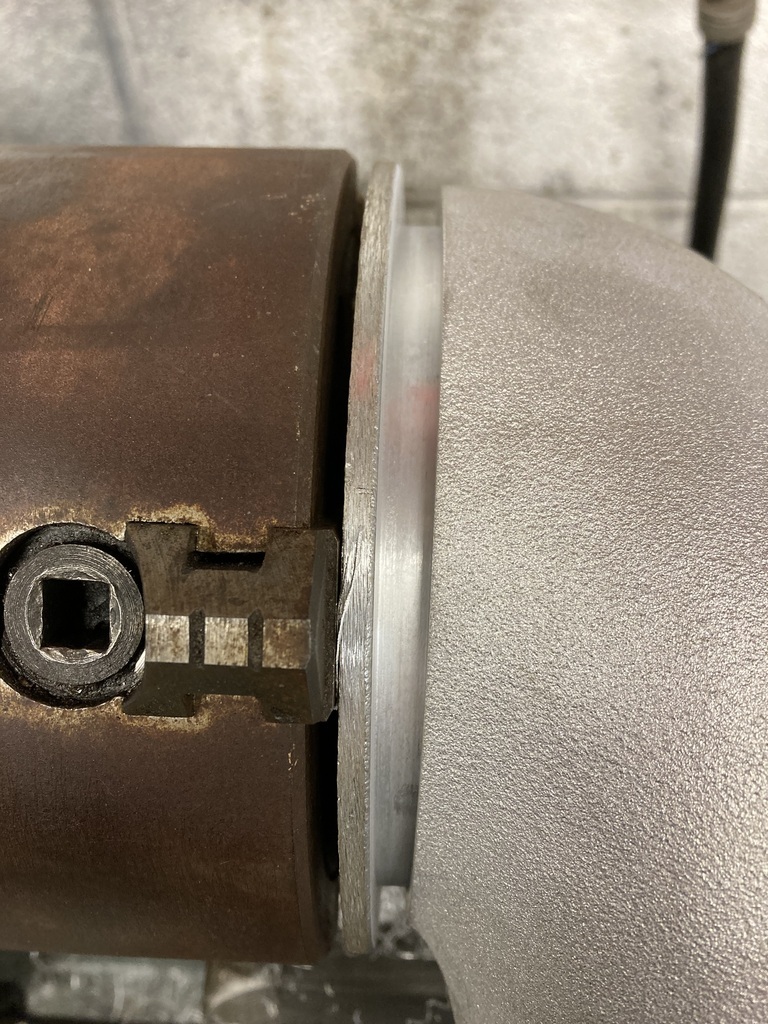

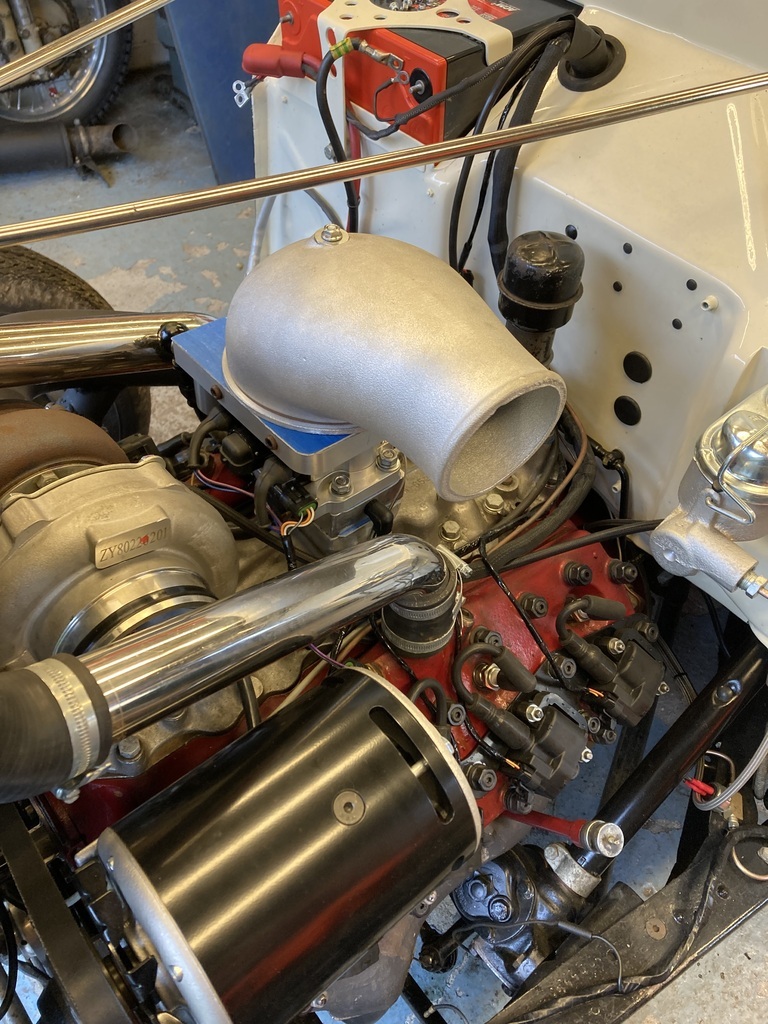

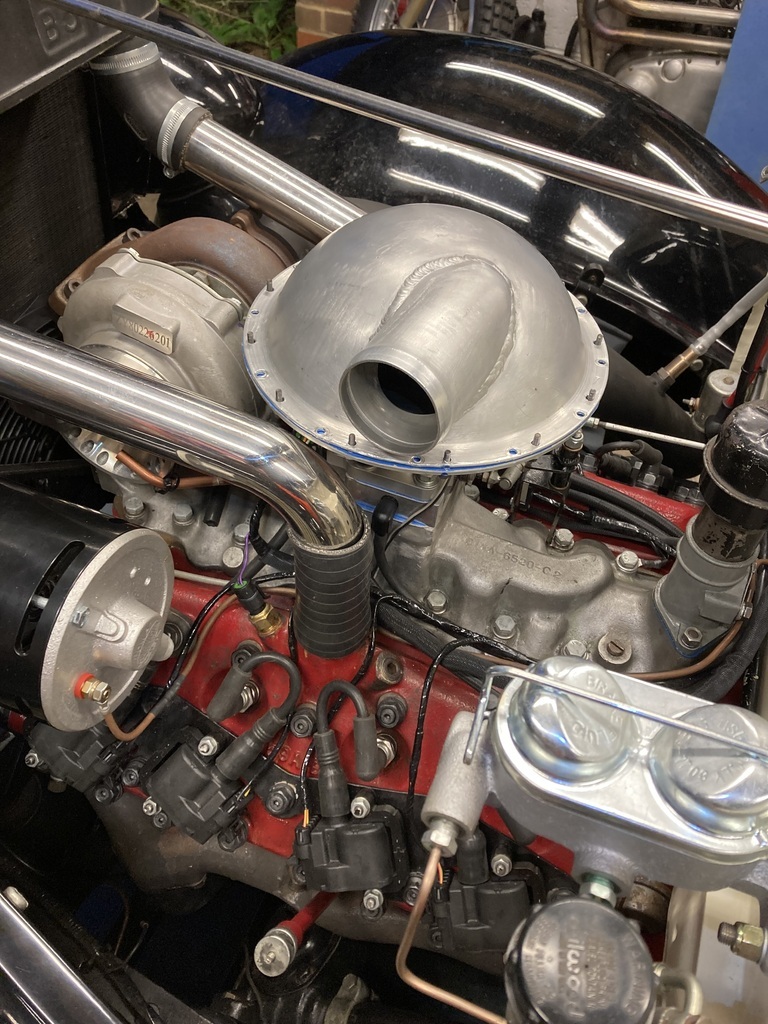

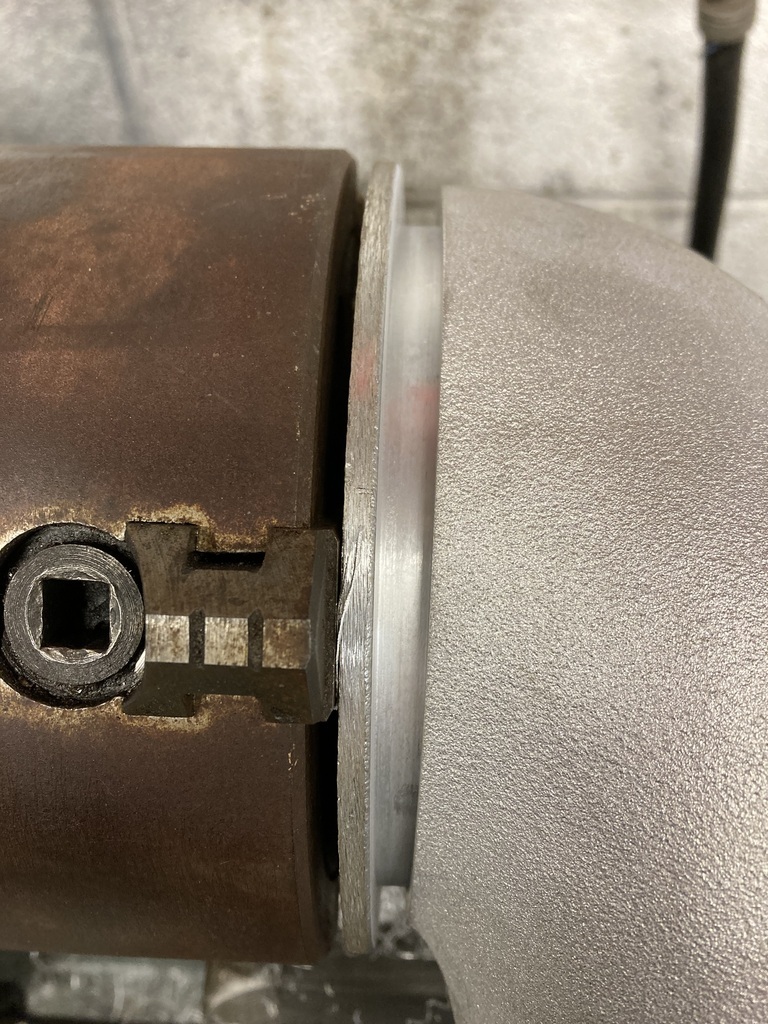

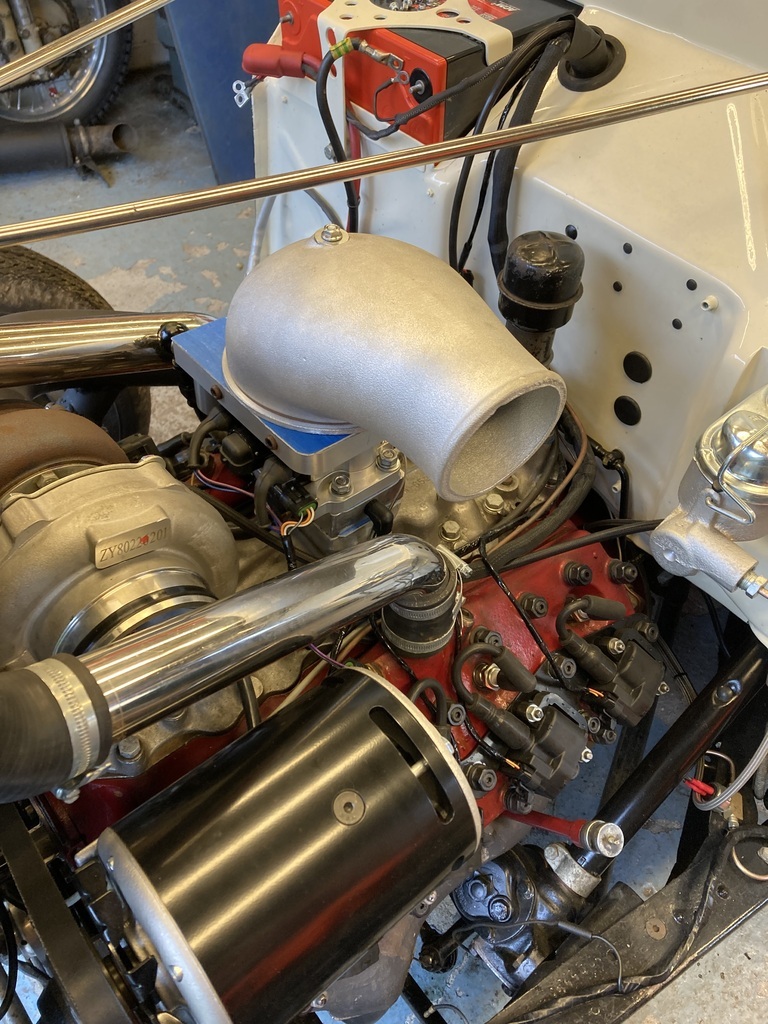

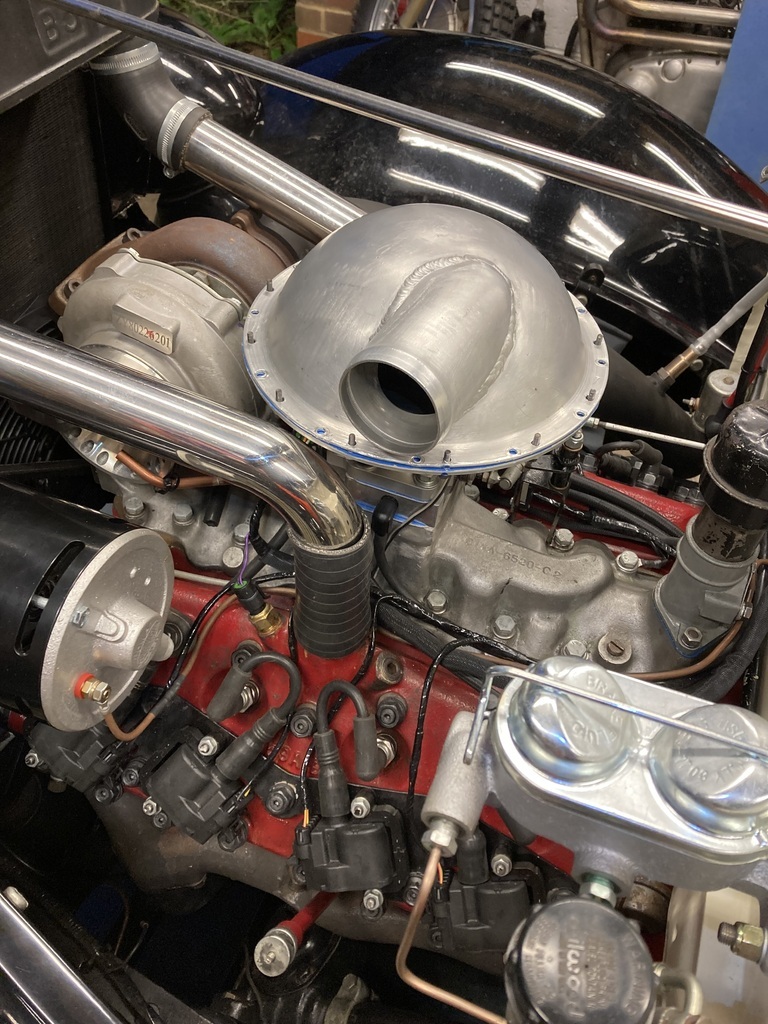

With the intercooler in place I would need to re-jig the position of the turbo outlet and the inlet of the carb hat for the charge pipe runs. The turbo outlet housing simply got swung round 180* so it was pointed towards the back of the radiator. The carb hat was a little more involved. Now I’ve never been overly happy the with carb hat, mainly because it looks like a WW1 helmet. The inlet now needed to be rotated 90*. It’s held down with 12 equally spaced fixings around its perimeter so it could be clocked in 12 different positions. That was the theory but I completely balls up the 12 equally spaced fixings and now it only fits in one position which has the inlet in the wrong position. 😕 This basically gave me me an excuse to try something different. I really liked the cast Holley carb hats and because they use a single, centre fixing stud can be rotated 360* for optimal positioning.  The Holley hats are designed to fit the industry standard 5 1/8” filter neck but I’ve got a Weber DGAS style throttle body. Now, I swear you could get a Weber to Holley filter adapter. After much searching they proved fairly elusive especially in this country. The closest I found was a listing on EBay which looked like a copy of a real one from what I remembered but some of the dimensions were off for a Holley filter. I purchased both and hoped for the best. They both arrived.  The adaptor was abit of a let down. The quality of the casting wasn’t great but what really had me miffed was the machining on the base.   The base has been machined on two different angles across the face. I had a moan to the seller about it and they came back saying it’s an adaptor for a BMW and the base is machined like that to keep the carb level. That’s fine but nowhere in the listing did it mention BMW or the flange discrepancy! I was going to to have to modify it anyway so I continued with it as there was just enough material left to square it off. This I did know wasn’t going to fit.  The register was 1/16” (1.5mm) oversize on the adaptor but I took a punt that there would be enough material to lose that. The adaptor was chucked up in the lathe and squared up as best as you can on a casting to machine the base flange flat.  Immediately after taking the first cut I knew things had gone wonky but I was committed now and had to see it through to the end. What I realised was the four mounting bolt holes had been plunged to create a flat surface to clamp on to. The plunge had been referenced from the angled flanged face not the inside face as I’d assumed it would have been but in retrospect that makes sense as it means the same hardware can be used with the considerable difference in flange thickness. By the time I’d faced the flange flat I had lost two mounting pads.🙁  A problem for later… I changed over to a 4-jaw to be able to centre the filter base register.  Machined the register to the Holley 5 1/8”.  The carb hat now fitted but wouldn’t go all the way home.  This was due to the machining in the carb hat not being as deep as the register on the adaptor.  I was filled with dread on how to hold and machine the carb hat but then had another look at the adaptor and realised it would a lot easier to machine that down to fit the hat rather than the other way around.  Voila!  The supplied hold down stud was 1/4” UNC and too long. I made a shorter M6 one to match the drilled and tapped hole in the adaptor.  I excitedly mocked it up and… well… I hated it. It looked stupid.🫣  I quickly removed it and moved it into the parts for future use section. At least I didn’t need to find a solution to the missing mounting pads now. I guess I’ll have to build that ProCharger set-up now around the carb hat. 😆 Back to my WW1 helmet… 😔 I worked out that by rotating the lid into its new position that all the studs fell roughly in the middle of all the previous mounting holes.  I then simply re-drilled all the stud holes and achieved the most long winded way of drilling 12 holes!  |

| |

Last Edit: Jan 15, 2024 21:20:49 GMT by Enbloc

|

|

|

|

|

|

|

|

|

|

I found this thread the other day and have been on the roller coaster ride catching up.

It is fighting you all the way but the engineering solutions are great to see.

Looking forward to all your hard work paying off.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

Looking at the Holley style top hat, from my perspective, I think the issue might be the injector plate underneath, the gasket dosent help being blue and its all VERY square and modern, , it hides under the helmet, but now the extra 12 holes now makes the helmet even worse (as you may guess I'm not a lover of it  ) Putting my engineering head on and being constructive, My thoughts on the Holley top hat would be paint it matt black, and get the injector plate black anodised too, or paint for that matter, or even a more contentious idea, which would be hard to do, Strip and mask the injector plate very well and heavy shot blast the top and sides and leave it to go grey over time, make it look older than it is, |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

ds67

Part of things

Posts: 20

|

|

Jan 24, 2024 19:46:29 GMT

|

|

What a great project !

I just discovered the thread and read it with great interest as I am planning on a similar project, using a Retroject on a turbocharged application. I may have missed it, so bear with me if you already mentioned it. But what kind of power are you aiming at? I believe the two injectors coming with the Retroject will limit it to around 150-160 hp, and that is in NA form. Boost usually needs a richer mixture.

|

| |

|

|

|

|

|

Jan 24, 2024 19:58:59 GMT

|

Looking at the Holley style top hat, from my perspective, I think the issue might be the injector plate underneath, the gasket dosent help being blue and its all VERY square and modern, , it hides under the helmet, but now the extra 12 holes now makes the helmet even worse (as you may guess I'm not a lover of it  ) Putting my engineering head on and being constructive, My thoughts on the Holley top hat would be paint it matt black, and get the injector plate black anodised too, or paint for that matter, or even a more contentious idea, which would be hard to do, Strip and mask the injector plate very well and heavy shot blast the top and sides and leave it to go grey over time, make it look older than it is, Or put a circular cover over the plate, like an air filter looking thing. No function, but it would look more fitting maybe? |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

|

|

I found this thread the other day and have been on the roller coaster ride catching up. It is fighting you all the way but the engineering solutions are great to see. Looking forward to all your hard work paying off. Thanks, glad you’re enjoying the journey. Its still fighting me now… What a great project ! I just discovered the thread and read it with great interest as I am planning on a similar project, using a Retroject on a turbocharged application. I may have missed it, so bear with me if you already mentioned it. But what kind of power are you aiming at? I believe the two injectors coming with the Retroject will limit it to around 150-160 hp, and that is in NA form. Boost usually needs a richer mixture. A good, traditional roots style supercharged Flathead is around 250hp maybe nudging 300. I expect a turbocharged one to be on par with that, at least. This is a lot of guesstimating as proven, reliable figures are not that easy to come by and turbocharged is non-existent. I went through the same thoughts regarding supplied injection sizing as this throttle body was never really designed to be on an engine of this size. I went through the injector flow numbers with my tuner and he seemed to think they wouldn’t be an issue? I think it’s a case of suck it and see wether the injectors will run out of flow and if they do I can always step up a size. My saving grace is that because the engine is such a poor breather and has a relatively low rev range that it’s fuelling requirements are not as much as you’d expect. Where did you get the figure of 150-160hp limit from? |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

|

|

Looking at the Holley style top hat, from my perspective, I think the issue might be the injector plate underneath, the gasket dosent help being blue and its all VERY square and modern, , it hides under the helmet, but now the extra 12 holes now makes the helmet even worse (as you may guess I'm not a lover of it  ) Putting my engineering head on and being constructive, My thoughts on the Holley top hat would be paint it matt black, and get the injector plate black anodised too, or paint for that matter, or even a more contentious idea, which would be hard to do, Strip and mask the injector plate very well and heavy shot blast the top and sides and leave it to go grey over time, make it look older than it is, Or put a circular cover over the plate, like an air filter looking thing. No function, but it would look more fitting maybe? You’re both right, the squareness, shininess and bright blue gasket are all out of place. My main issues with the aesthetics, which don’t really come through in the picture, is the Holley carb hat is completely out of proportion with everything else. The inlet alone is 3 1/2” and completely dominates. The other reason I didn’t like it is the engine has a general low profile but I’ve ended up with a stack of components all concentrated in the middle. The taller, narrower Holley carb hat just exaggerated this even more. |

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

|

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

ds67

Part of things

Posts: 20

|

|

Jan 26, 2024 22:44:19 GMT

|

Retroject injectors are 480cc. At 85% duty cycle, two of them allow for about 155 hp, according to the Megasquirt injector size calculator. Bigger Pico injectors look to be available, up to 840cc, here for example. That would allow for 270 hp, though tuning at idle and low throttle may become challenging. You shall look at your injectors duty cycle next time you go for a tuning session. You don’t want them to go over 90%. If they max out you may end up with a lean condition potentially causing damage to the engine. I will follow your progress with a lot of interest as you are ahead of me. So I may learn from your experience. I’m looking at about 200 hp for my project, so 630cc injectors may do the trick and may be a bit easier to tune at idle and low engine load. Is there a way to get email notifications when answers are posted to this thread? I could not figure it out. |

| |

Last Edit: Jan 26, 2024 22:50:17 GMT by ds67

|

|

jimi

Club Retro Rides Member

Posts: 2,236

|

|

|

|

Is there a way to get email notifications when answers are posted to this thread? I could not figure it out. Go to your forum profile page LINKY click on "Notifications", then "Edit Profile" then "Notifications" again, there you can select your email notification preferences  |

| |

Last Edit: Jan 27, 2024 1:05:45 GMT by jimi

Black is not a colour ! .... Its the absence of colour

|

|

Enbloc

Part of things

Posts: 399

|

|

Jan 27, 2024 22:26:38 GMT

|

Always on the lockout for an alternative! |

| |

|

|

|

|

)

)