|

|

|

Mar 12, 2024 17:48:10 GMT

|

Hi all. I have been reading this excellent forum for a while but have only contributed a little so far. I particularly enjoy the build threads, such as the 32 Ford 5 window, the quick Elan, the flat 6 Imp, the Stratos etc. For just on 20 years now I have been working on my project at my home in Port Elizabeth , South Africa. Late last year it looked like this.    |

| |

Last Edit: Mar 12, 2024 17:51:28 GMT by Fred W B

|

|

|

|

|

|

|

Mar 12, 2024 17:54:46 GMT

|

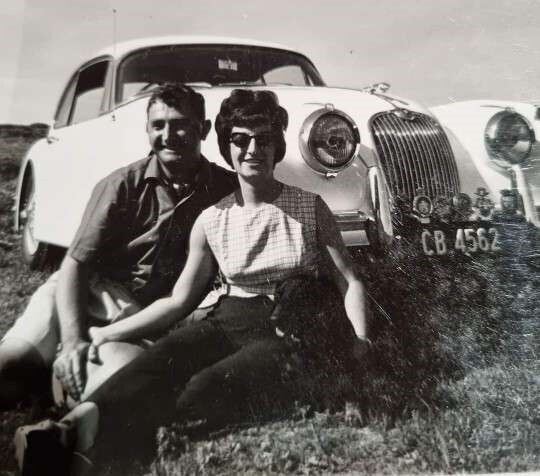

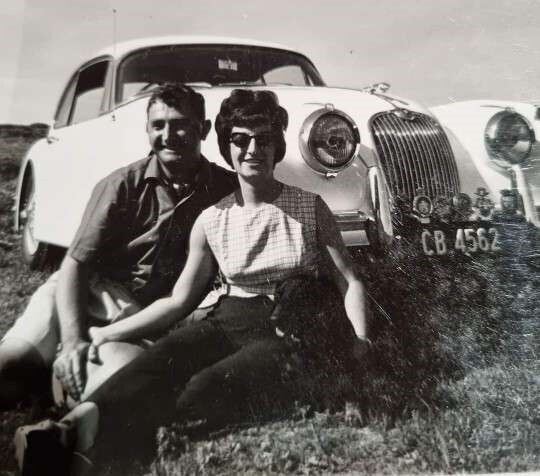

You might ask, why a build thread for a car that seems to be complete. That is because so far I have only completed a "dry" unpainted build. Why has it taken me so long? As is the case for many peoples projects I have to split my time and finances between holding down a job, maintaining a home and keeping up with all the other responsibilities of life. I also participate in other car related and motor sport activities. I raced 2 stroke karts, up to national level, for many years. More recently I have mechanically rebuilt and raced a street registered Birkin 7, the blue and silver car below. Birkin's were kits built in Durban South Africa, initially under licence from Lotus, and thus share a lineage with Caterham. My car was originally built in the 80s, so qualifies as retro? Although the Mazda 12A rotary motor is highly tuned, it's not really a race car and I intend to replace the drivetrain for MX5 eventually as its really too noisy and raw for the street as it is. I take the windscreen off for the track. I'm lucky to have friends who invite me to share or race their cars, one of whom owns the orange and silver 7 below. We have shared this in the annual 3 hour race at our local track the last few years. Another friend has a good stable of race, rally and classic cars which I help him with on occasion. The Jaguar XK 150 I show below is unusual for South Africa in that it is left hand drive. A sublime car to drive which I particularly enjoy as my father had one just before I was born. On the track this year we are campaigning the race Escort below. These are my only other retro credentials.        |

| |

Last Edit: Mar 12, 2024 18:06:19 GMT by Fred W B

|

|

|

|

|

Mar 12, 2024 18:09:01 GMT

|

|

To get to where I am now on my project I:

Built a mock up chassis to sort out the component placement and ergonomics.

Drew up and had manufactured an adaptor plate and flywheel to mate a Rover V8 engine to a Audi 500E AAZ 016 transaxle.

Made exhaust manifolds.

Bought a book to teach myself glass fibre work (plus got advise from some of the best in the business).

Scaled up a 1:18 scale Lola T70 model.

Made a body pattern, moulds and the body sections.

Made a space frame chassis.

Designed and made wishbone suspension.

Had drive shafts, fuel tanks etc, etc made up.

Imported some parts from the USA and the UK.

Built up all the oil, fuel, cooling, braking, suspension, steering and electrical systems in the chassis, and tacked on brackets and welded in insets / weld nuts for all the required brackets / attachment points.

Mounted and gapped the body sections.

Stripped back the chassis and fully finished all welding.

In this thread I intend to document each system as it is fitted, and note the weigh of each component / assembly.

|

| |

Last Edit: Mar 12, 2024 18:10:09 GMT by Fred W B

|

|

|

|

|

Mar 12, 2024 18:11:04 GMT

|

I have had help and advise from many people over the years, in particular from the participants on 2 car building forums. These being www.locostbuilders.co.uk and www.gt40s.com. Sadly the traffic on locostbuilders has dropped off to a trickle over the last few years. On the other hand gt40s.com is still very active. I have a thread there where I documented the long blood sweat and tears story of making the pattern, moulds and parts, if your should like to read more about that www.gt40s.com/forum/lola-t70-lounge/19604-canamsa-sa-stratch-build.html. Unfortunately it seems that the locostbuilders site, that i used to host all the early photos, has just fallen over so the photos are not visible. |

| |

Last Edit: Mar 12, 2024 18:24:22 GMT by Fred W B

|

|

|

|

|

Mar 12, 2024 18:12:55 GMT

|

I also enjoy threads where people document their home and or workshop space and facilities. Although I have a good size double garage to work in, I am not particularly well equipped. I cut steel with hacksaw, angle grinders and chop saw. Aluminium brackets I make from flat bar and channel using a wood working band saw, hole saws and belt sander. I have documented my garage here, www.garagejournal.com/forum/threads/not-the-best-damn-garage-in-south-africa.248410/although that thread is quite old. I have since upgraded the belt sander and added a TIG welder in addition to my MIG welder. I do most of my welding with TIG now. Aluminium welding I have to contract out. Fortunately I have various friends who own or have access to equipment such as lathes, milling machines, guillotines and press brakes, so I rotate favours amongst them. Port Elizabeth has historically been an engineering town, with SA's motor industry starting here. We also have an active community of car restorers and race enthusiasts, so most things can be done. |

| |

Last Edit: Mar 12, 2024 18:18:15 GMT by Fred W B

|

|

|

|

|

Mar 12, 2024 20:26:40 GMT

|

Very cool fred W B . I love the T70, and the rest of the cars you posted are really nice too. I'll check out your thread on the FT40 site later. |

| |

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

|

Mar 12, 2024 20:26:45 GMT

|

|

This is excellent. I love T70s, hard as nails.

|

| |

|

|

|

|

|

Mar 12, 2024 20:46:14 GMT

|

|

What a cool car!

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,882

Club RR Member Number: 39

|

|

Mar 12, 2024 21:06:19 GMT

|

|

Was one of my absolute favourite threads on Locost Builders - an epic build.

|

| |

|

|

|

|

|

Mar 13, 2024 11:10:59 GMT

|

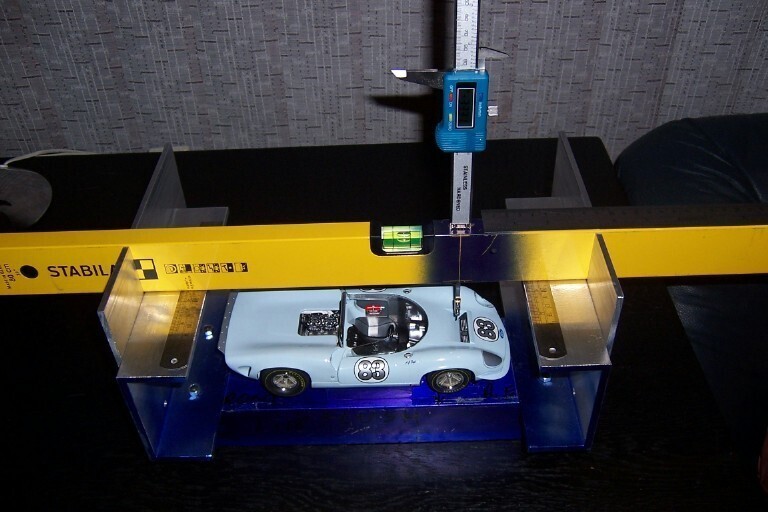

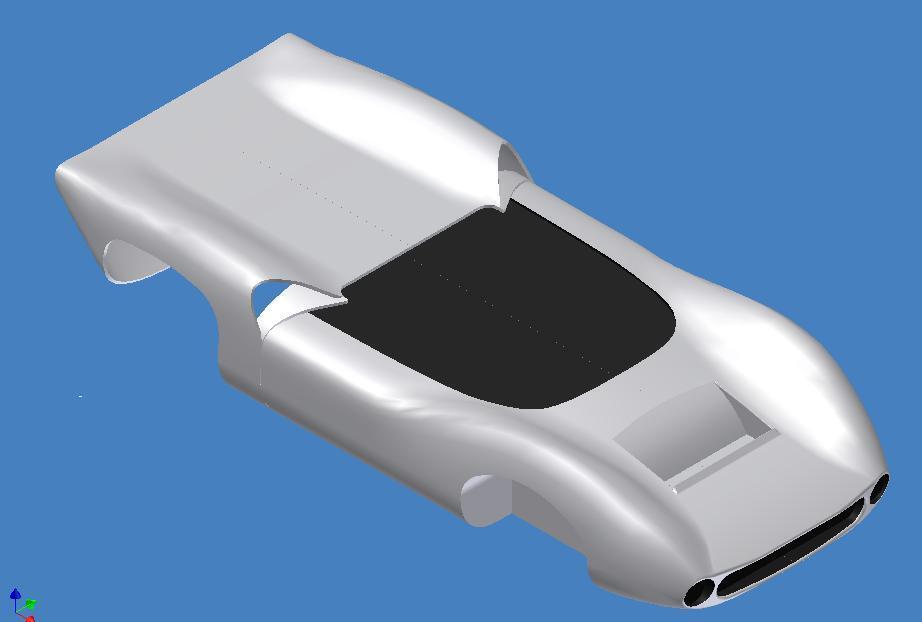

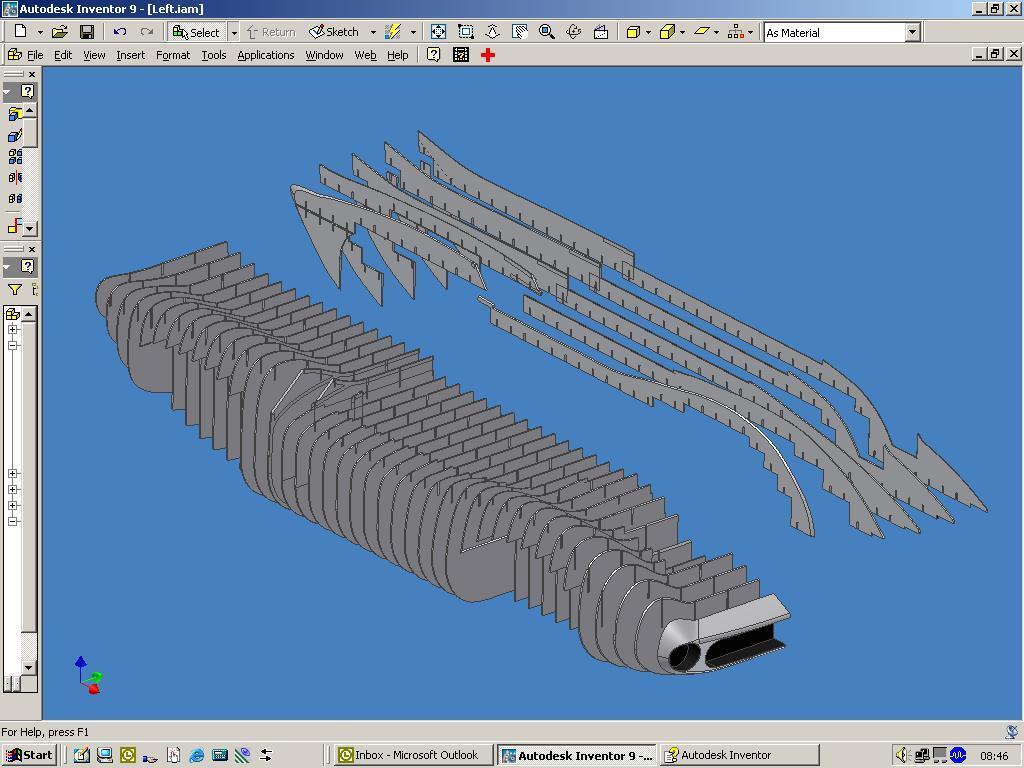

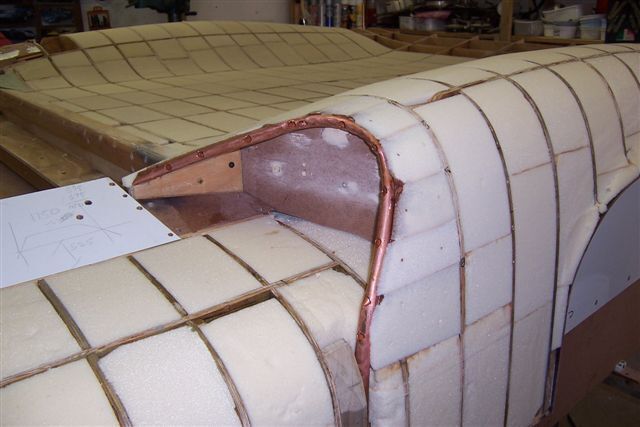

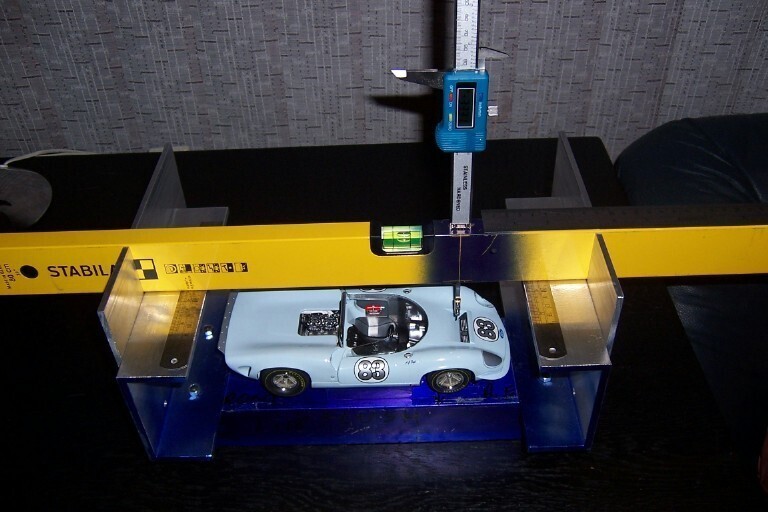

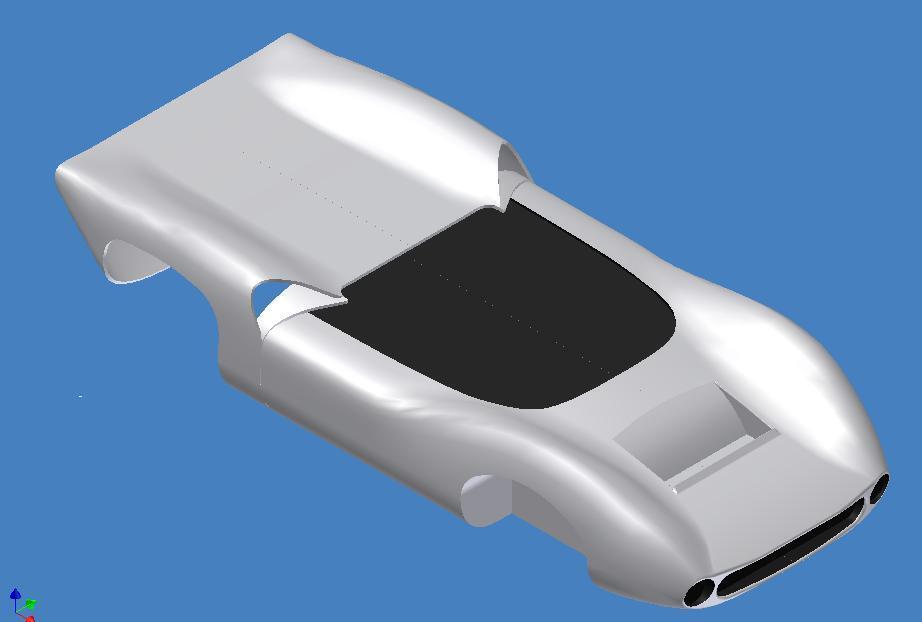

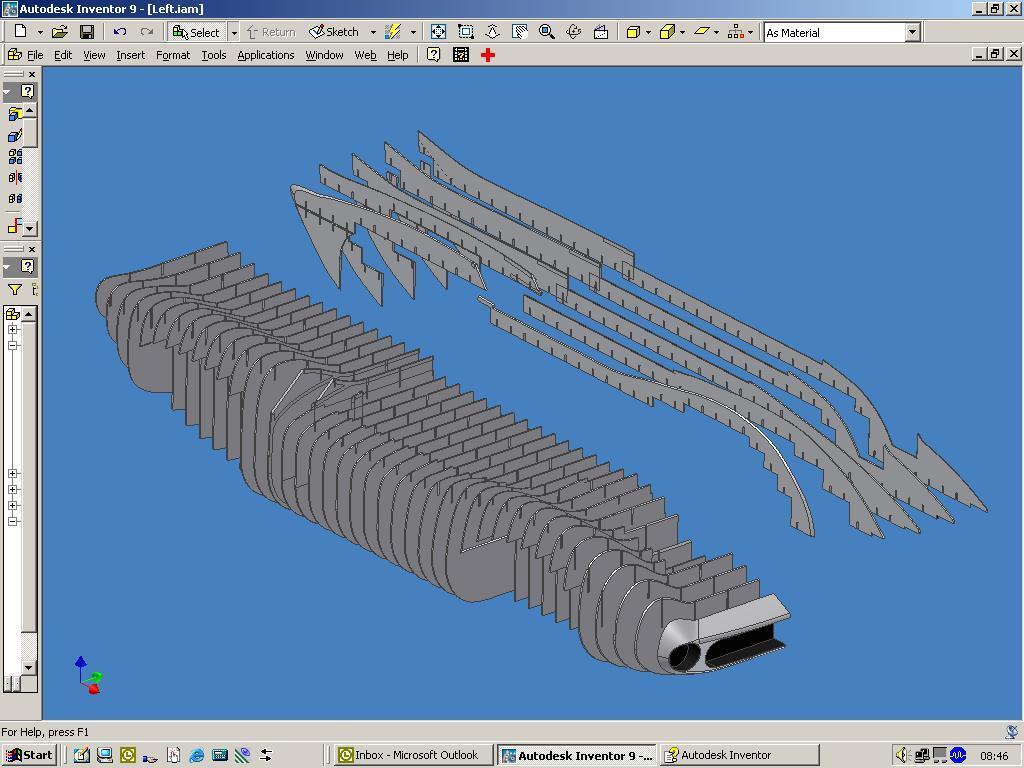

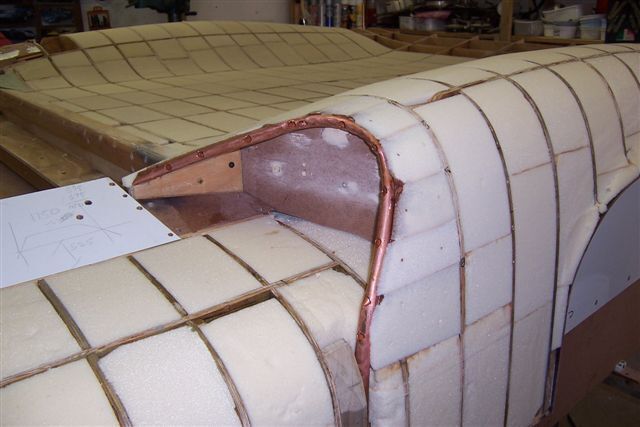

Thanks for the kind responses Guys. Unfortunately the photos have disappeared from the other thread so a short version and some photos here to explain how I made the pattern. In order to measure the 1:18 scale model I made up a 3 axis measuring jig from alloy channel section and flat, steel rules, a straight edge and a digital vernier. Then with the aid of a colleague Andrew, I measured the offset of the body surface from the datum base at every point on a 5 mm x 5 mm grid, and recorded the measurements on a large piece of paper. Andrew then used this data and many reference photo's I had found in books, magazines and on the net to draw the body surface in Inventor - one sentence that describes many hours of work. I even corresponded with the owner of a real T70 in the states with regard to some of the details. Originally I had not intended to attempt an exact replica, to stop any pedantic's telling me I have this and that detail wrong but once I went to all this trouble, it seems a pity not to get it as right externally as I could. We than used that data to produce drawings of many flat body sections (stations every 100 mm in the length) and some longitudinal stringers to position them, in DXF file format. These parts were then cut out on a CNC router from 8 mm plywood sheet. I have a friend with a router that can handle 8' x 4' sheets. The plywood was recycled from packing crates used to send stuff from GM Brazil to a GM plant here in Port Elizabeth. Once all 67 wooden parts were in hand I put the buck together. The parts were drawn with slots so that they clipped together and self aligned. I had 350 polyurethane foam blocks cut, to glue into the spaces to form the surface. The foam was sanded to shape and covered with filler. Following some adjustments to the shape it was then covered with a layer of chopped strand mat and resin, to give a solid base. This was then sanded to fair it, then coated with polyester auto body filler, and sanded again. Then the whole lot was sprayed with surfacing compound and finally finished to give a suitable surface for moulds. I did all the sanding and polishing, from 36 grit down to 1200 grit, by hand with a long board and sanding blocks. Got through 50 kg (110 lbs) of body filler.              |

| |

Last Edit: Mar 13, 2024 11:29:26 GMT by Fred W B

|

|

|

|

|

|

|

Mar 13, 2024 11:53:54 GMT

|

|

This thread is incredible already, looking forward to more!

|

| |

|

|

|

|

|

Mar 13, 2024 14:45:02 GMT

|

|

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,882

Club RR Member Number: 39

|

|

Mar 13, 2024 15:19:29 GMT

|

|

As far as I know the only commercial T70 kit is the Gardner Douglas GD T70 - That looks very much like one. Very nice

|

| |

|

|

|

|

|

Mar 13, 2024 17:49:05 GMT

|

|

Yes, thats a GD. Very nice kit. I'm not going to put Lola badges on mine

This is an extract from some correspondence I had with a Dutch guy who built one about 2011. I was quite chuffed with myself about it

"When I was at GD's the MD Andy Burrows asked me about the fellow from africa that is making his own bodywork, I offcourse knew right away about whom he was talking, so we chatted a bit, seems that have been topic of discussion in the UK kitcar scene aswell.

Andy said that he really liked the effort of doing things right, and also said that "one should give him all credit on perseverance, outstanding""

|

| |

Last Edit: Mar 14, 2024 5:12:57 GMT by Fred W B

|

|

|

|

|

Mar 13, 2024 18:35:23 GMT

|

Nice build The late Bob Akins T70 MK111B 6.2 SBC Lucas mech injection Hewland LG500 transaxle I maintained & crewed with in USA  A GD T70 I help the owner with mechanical work LS7 Porsche 996 GT3 transaxle    |

| |

|

|

|

|

|

|

|

Mar 16, 2024 19:35:56 GMT

|

Thanks for the pictures guys. Sean - you have worked on some cool cars. Last weekend was very exciting for me! Got the chassis and subframes back from paint and I am very happy with it. The colour is Basalt grey RAL 7012. Before painting the main chassis and rear section weighed about 119 kg (260 pounds), the zinc rich primer and polyurethane top coat added about 2 kg (4.5 pounds. I bolted the engine engine adapter / mount plate to the rear chassis section and mated that to the main chassis section to check it still fitted. Had to relieve some paint thickness in the mating faces. Started to remove the threaded plugs that I had screwed into all the various threads to protect them from the blasting and checked that a bolt turned nicely by hand into all the bushes. Currently busy with that as I am having to retap most of them.  |

| |

Last Edit: Mar 16, 2024 19:47:01 GMT by Fred W B

|

|

|

|

|

Mar 16, 2024 19:38:15 GMT

|

|

|

| |

|

|

|

|

|

Mar 16, 2024 19:39:13 GMT

|

A view of the engine bay showing various brackets for such as handbrake cables, fuel tank and lines, brake lines etc . The small structure in the center of the cockpit that supports the gearshift is slightly offset from center to give the driver more elbow room.  |

| |

Last Edit: Mar 16, 2024 19:39:40 GMT by Fred W B

|

|

|

|

|

Mar 16, 2024 19:40:20 GMT

|

Various body mounting and other subframes  |

| |

|

|

|

|