|

|

|

|

|

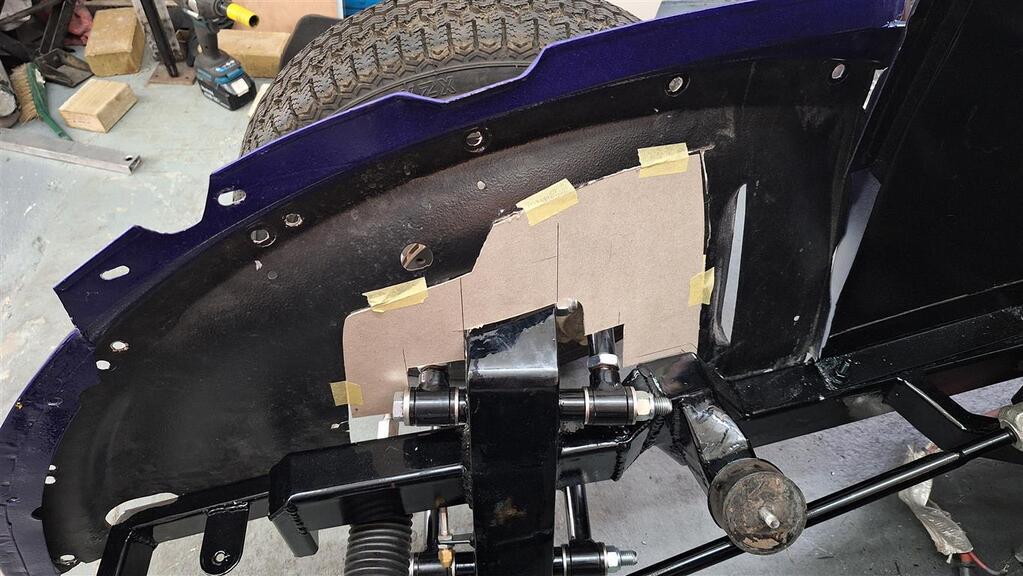

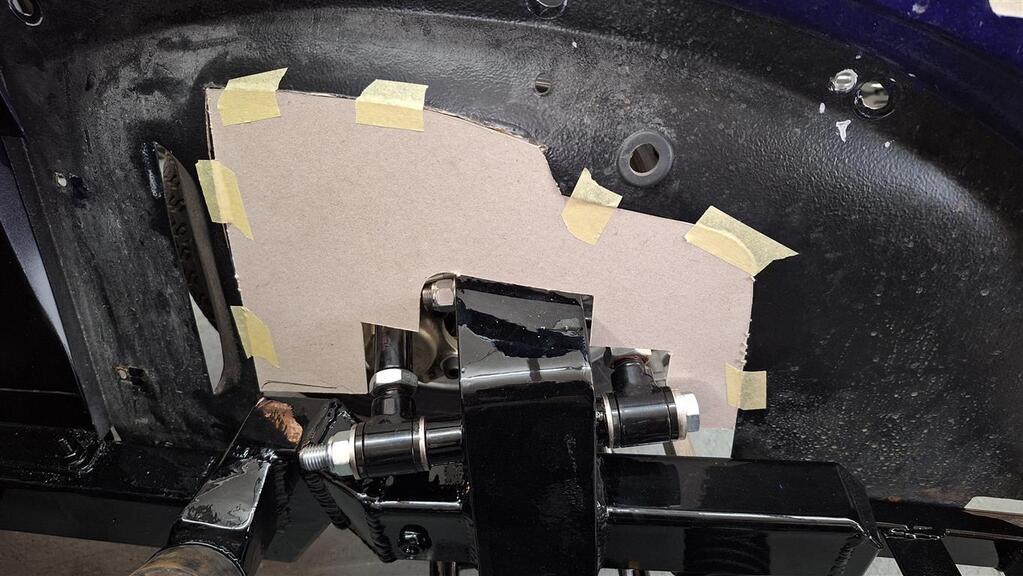

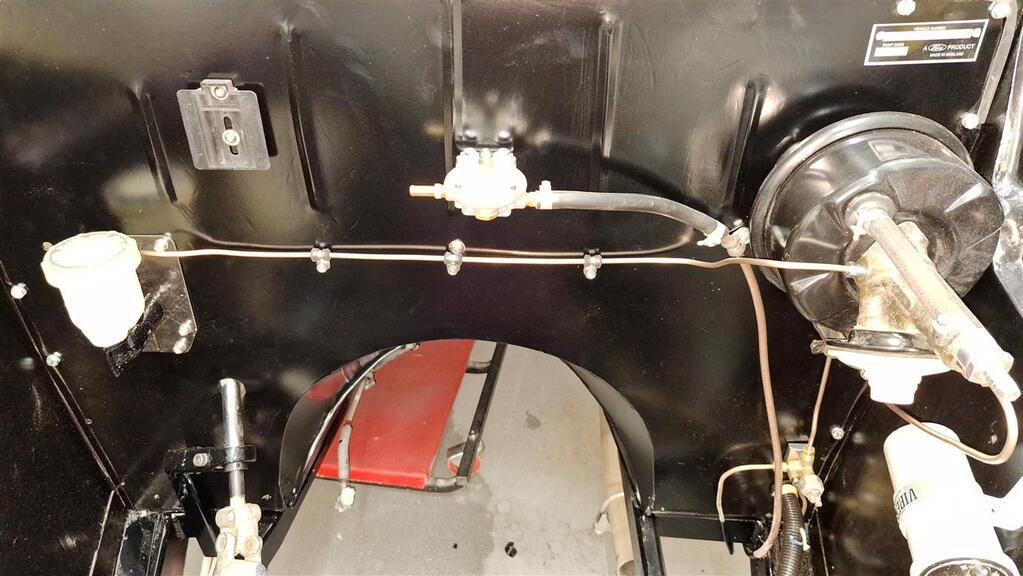

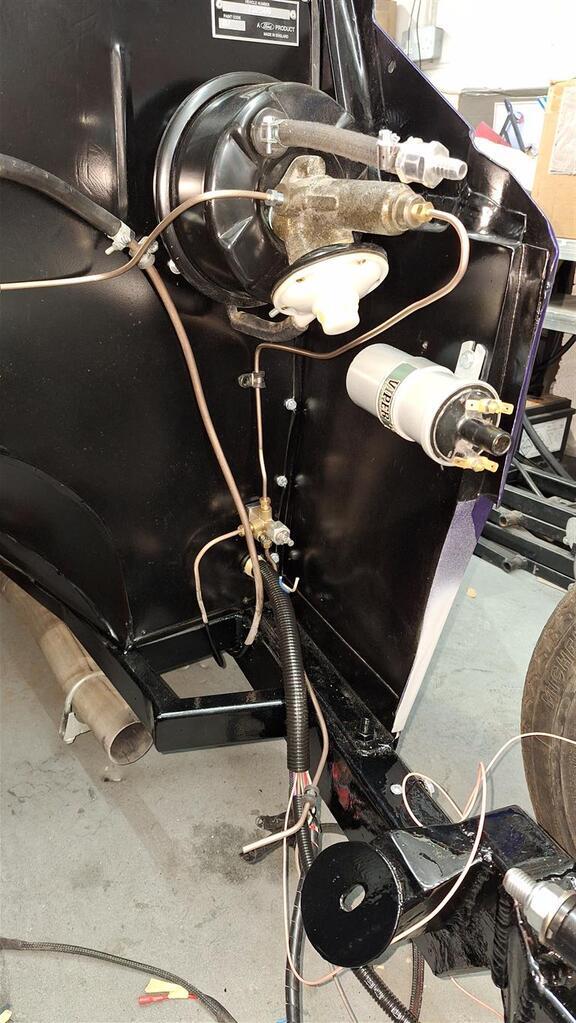

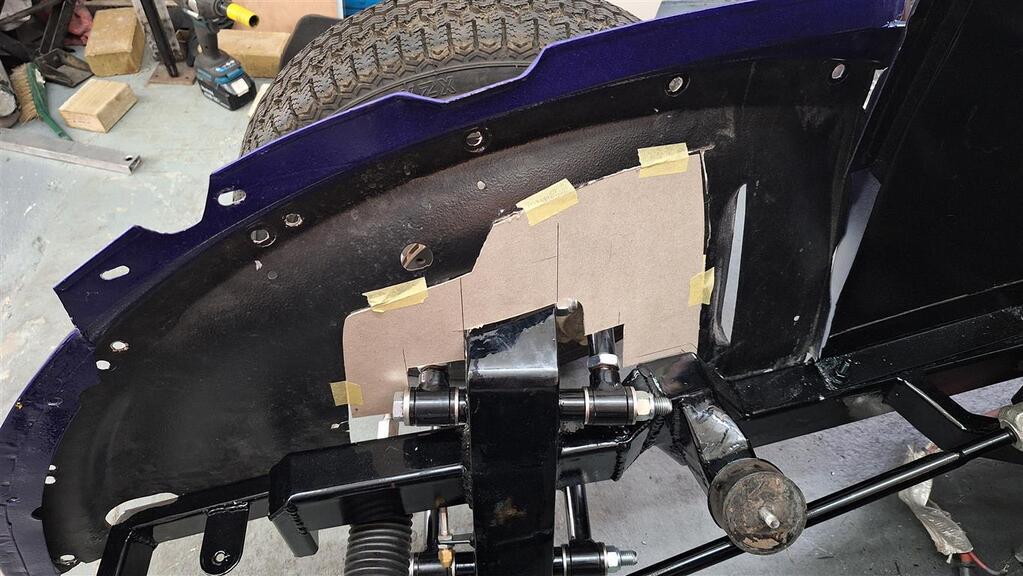

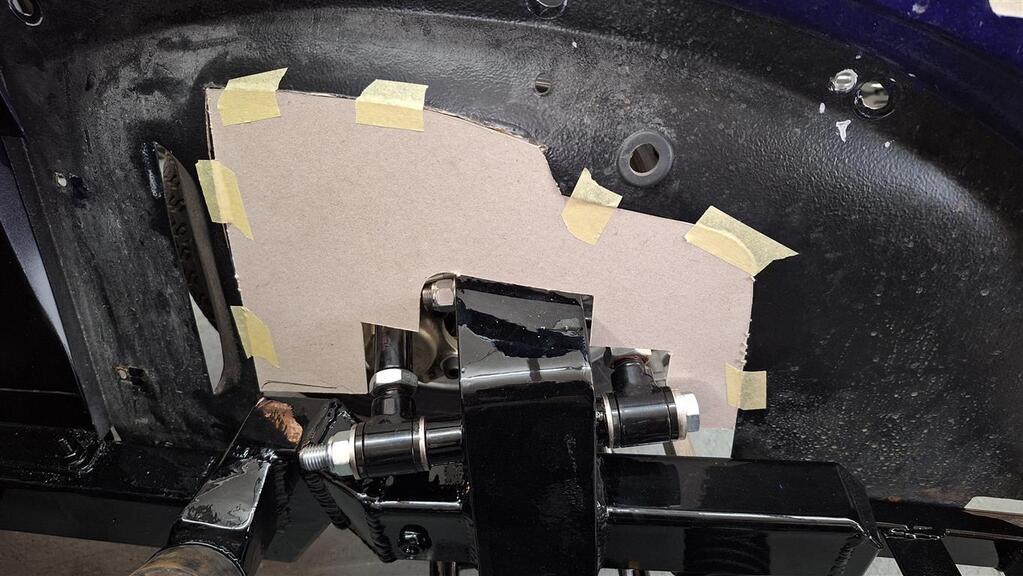

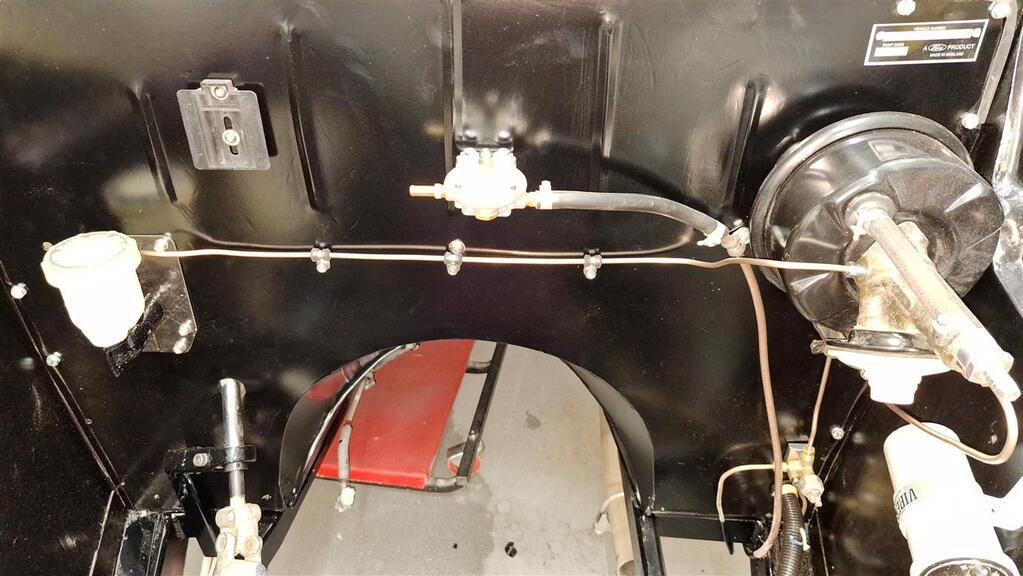

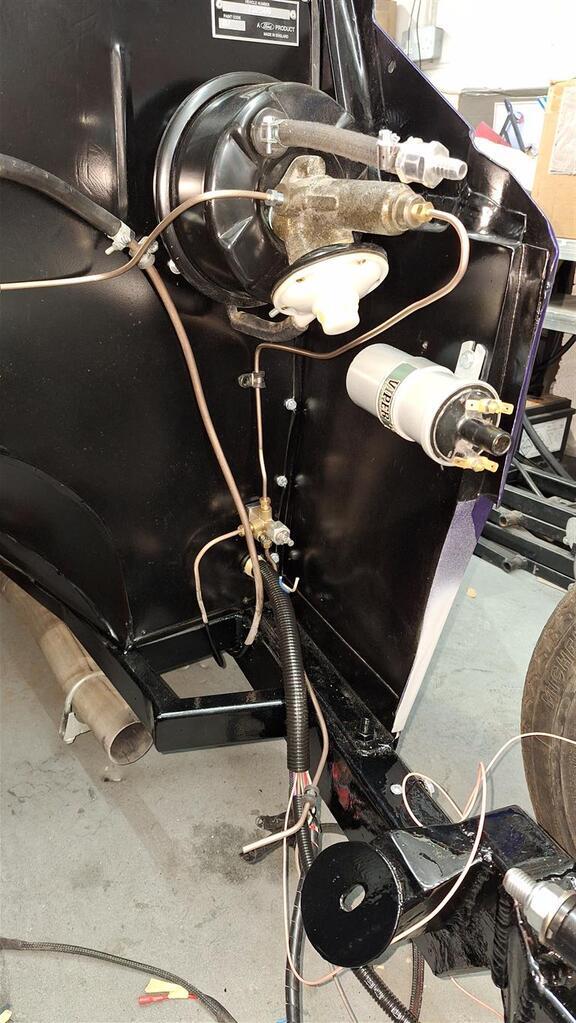

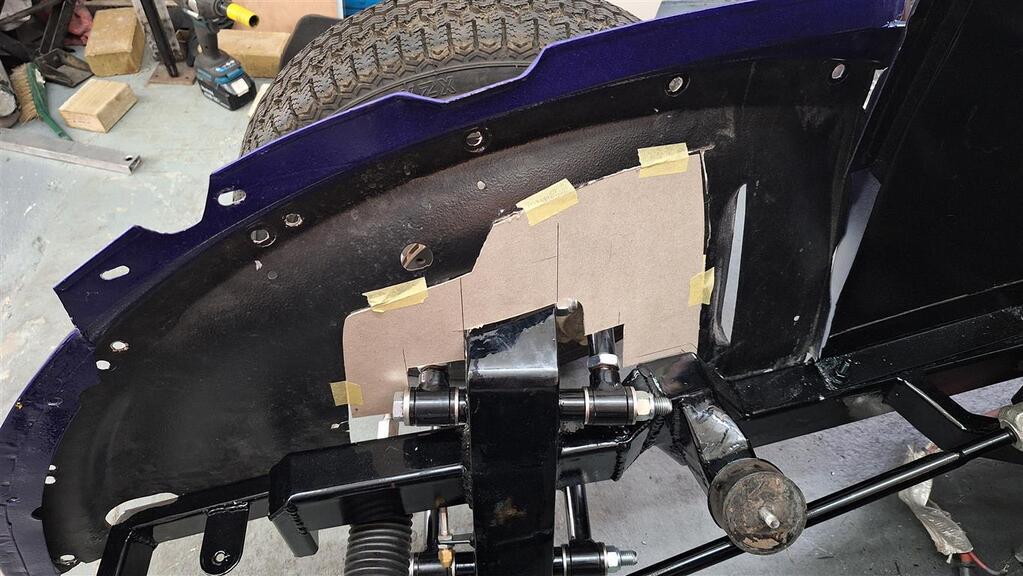

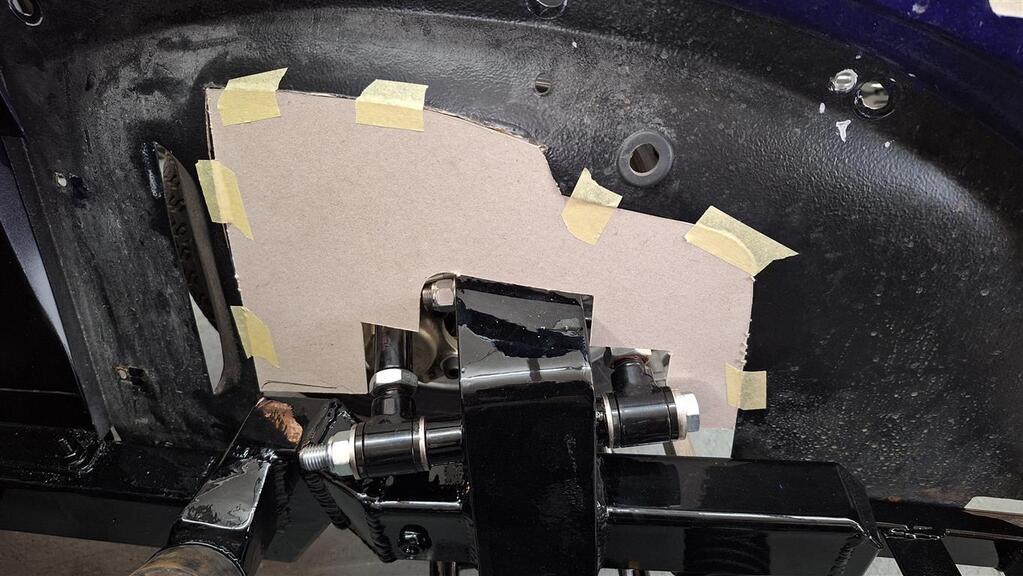

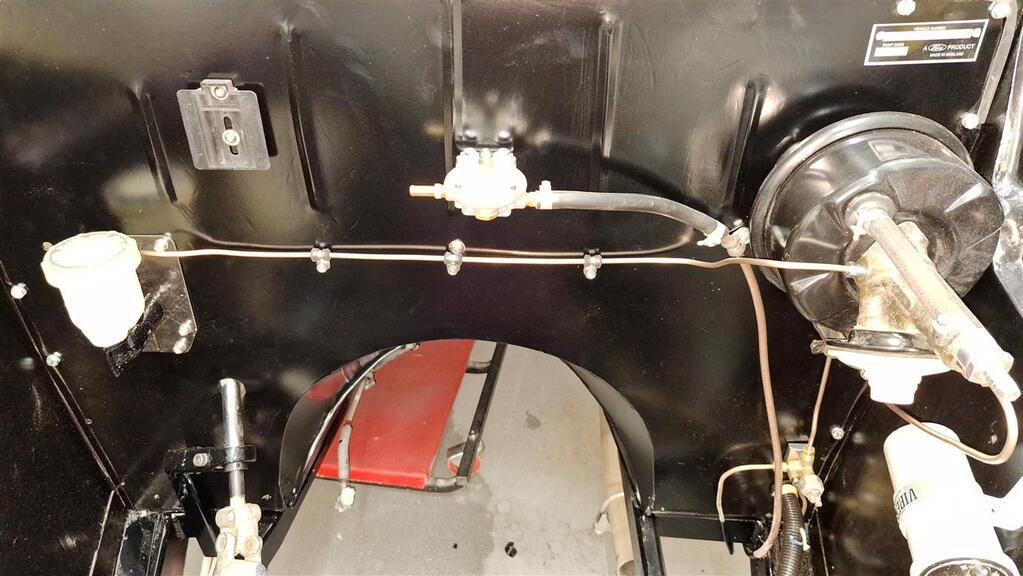

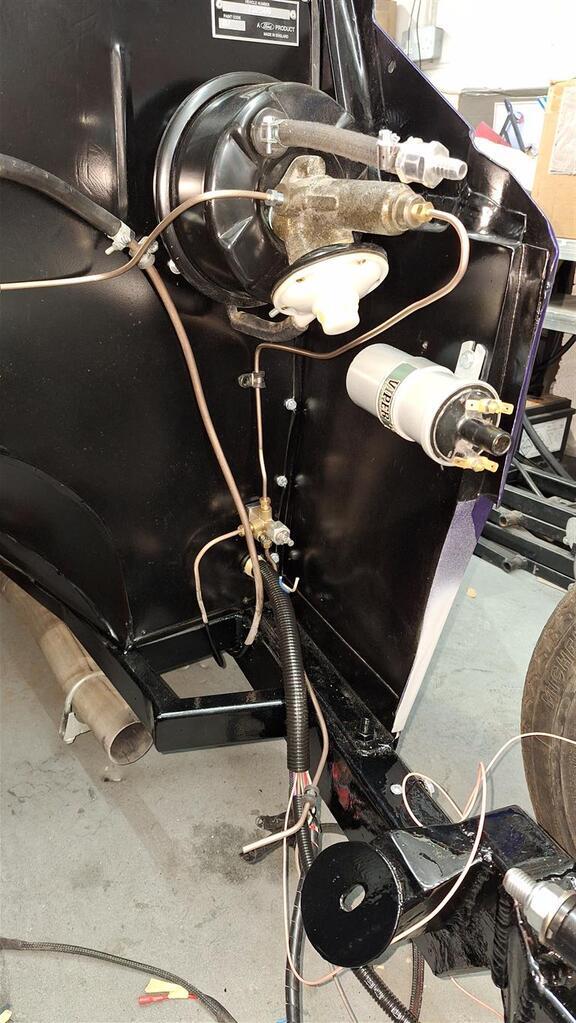

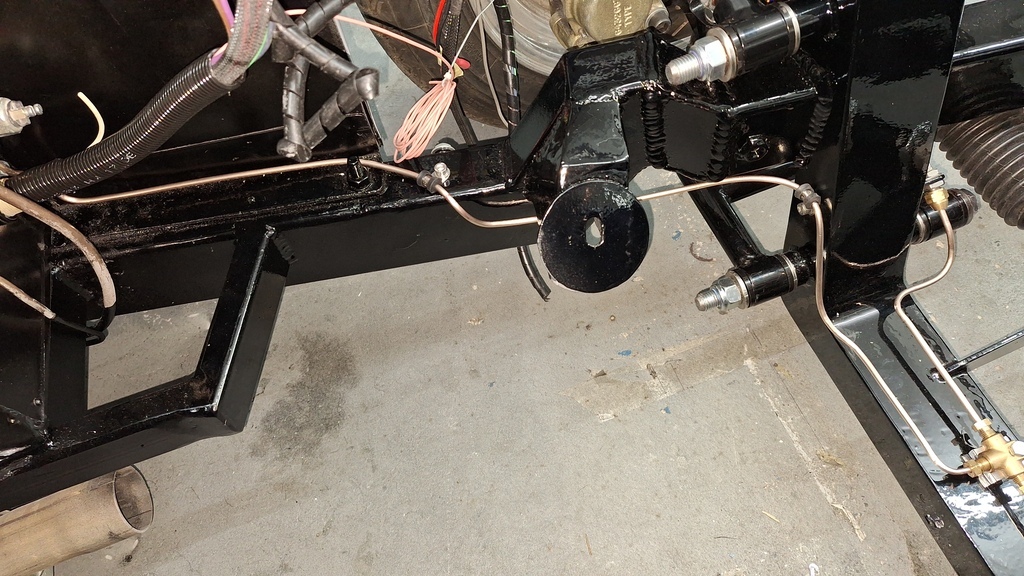

Yesterday I templated the new filler peices for the inner wings. I've decided to do them in steel as our ally is 2mm thick and does not bend easily. The inner wings have compound curves in them and also there is not much material at the back to fix to, so it will be far easier to shape in 1.2mm steel & weld them all back in. I may also cut holes in them and add a reverse scoop to allow hot air out of the engine bay.   After that I started getting the wiring back into the engine bay from the car. I slimmed the wiring down a bit and managed to get some of my cable trunking over it to protect it where it passes through the bulkhead sleeve. Much happier with that, no chafing possible now. The coil got fitted and then I started making the new brake pipes which always takes an age to work out the correct length and shapes. First one from M/C to servo fitted here;

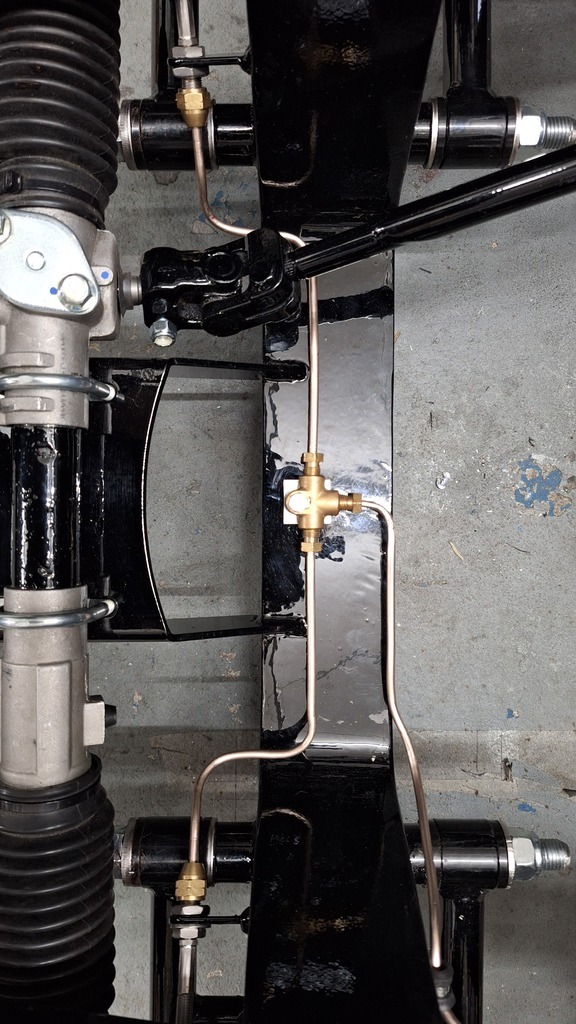

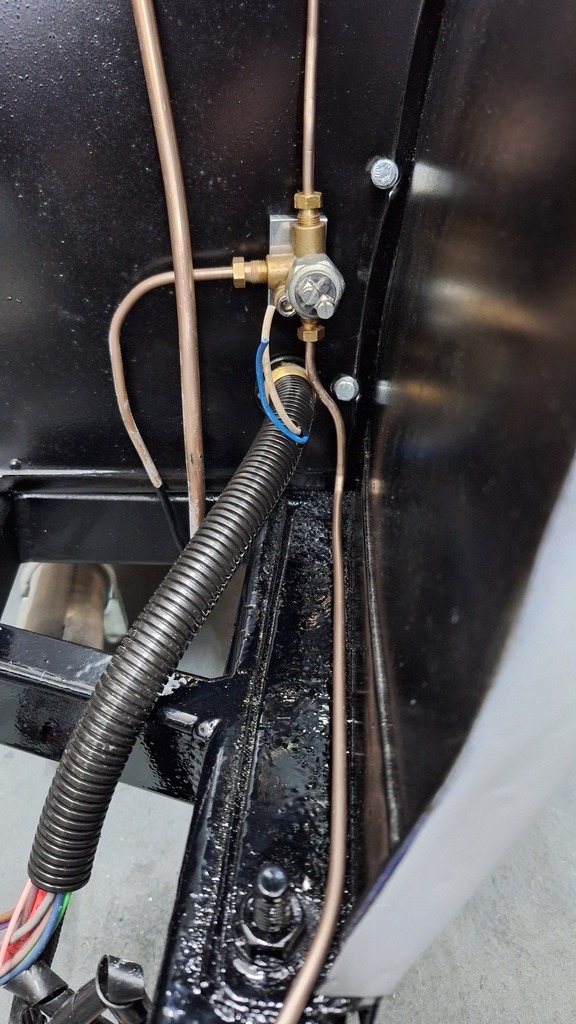

And the second one from the servo to the 3 way connector here - this is the MkII version  I used a bit of the old pipe to make a trial section for the take off for the front brakes, which is the loose bit at the bottom of the photo, should make that section a little easier to make tonight.  |

| |

|

|

|

|

Davey

Posted a lot

Resident Tyre Nerd.

Resident Tyre Nerd.

Posts: 2,350

|

|

|

|

Thanks everyone, I'd like to think it's what anyone would do for a friend in need. Davey, I do have a youtube channel, so I may think about that. If the world was full of more people like you Mark, it would be a much better place... |

| |

K11 Micra x3 - Mk3 astra - Seat Marbella - Mk6 Escort estate - B5 Passat - Alfa 156 estate - E36 compact

Mk2 MR2 T-bar - E46 328i - Skoda Superb - Fiat seicento - 6n2 Polo - 6n polo 1.6 - Mk1 GS300

EU8 civic type S - MG ZT cdti - R56 MINI Cooper S - Audi A3 8p - Jaguar XF (X250) - FN2 Civic Type R - Mk2 2.0i Ford Focus - Mercedes W212 E250

|

|

|

|

|

May 21, 2024 19:26:37 GMT

|

|

|

| |

|

|

|

|

|

May 21, 2024 22:48:01 GMT

|

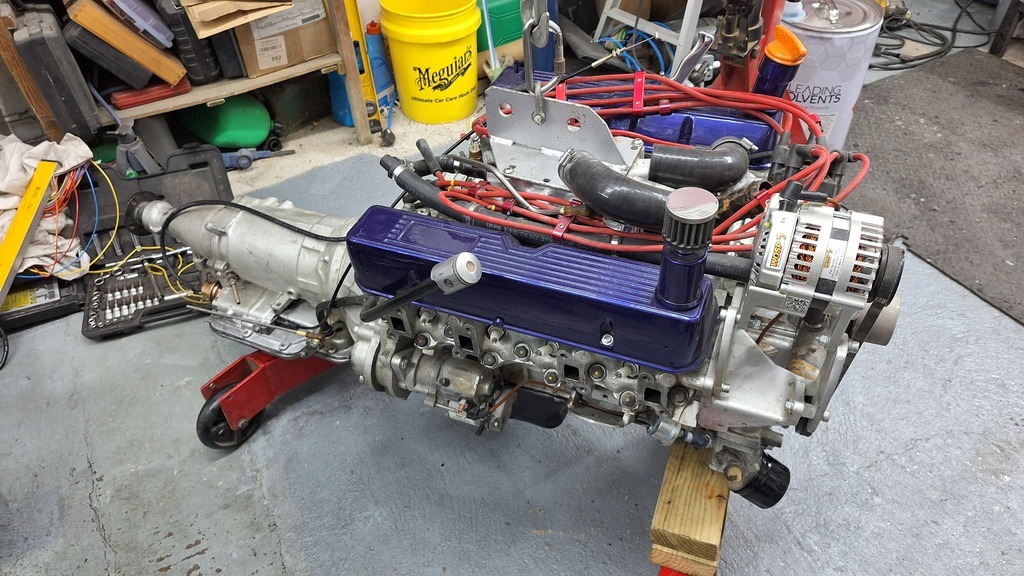

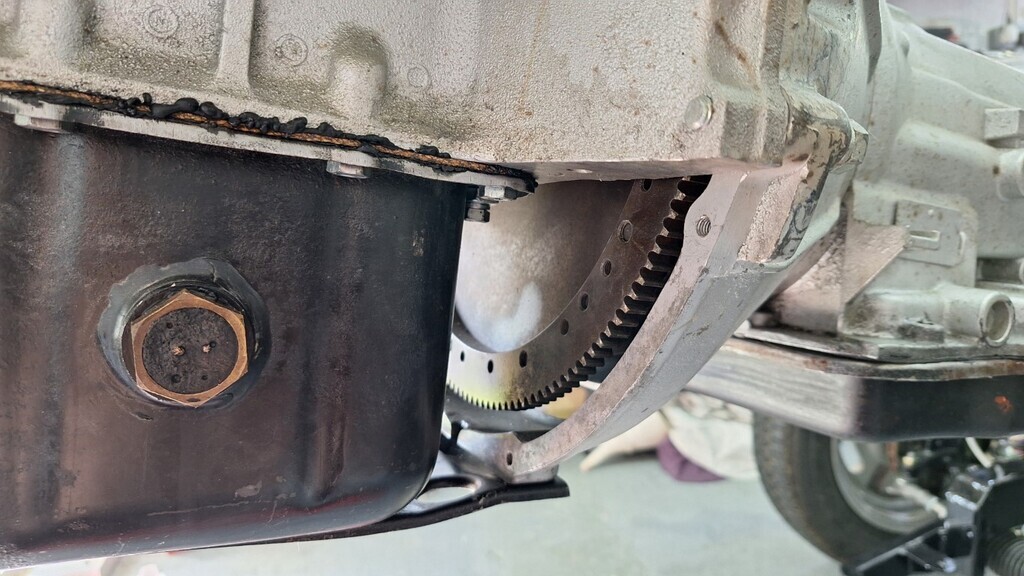

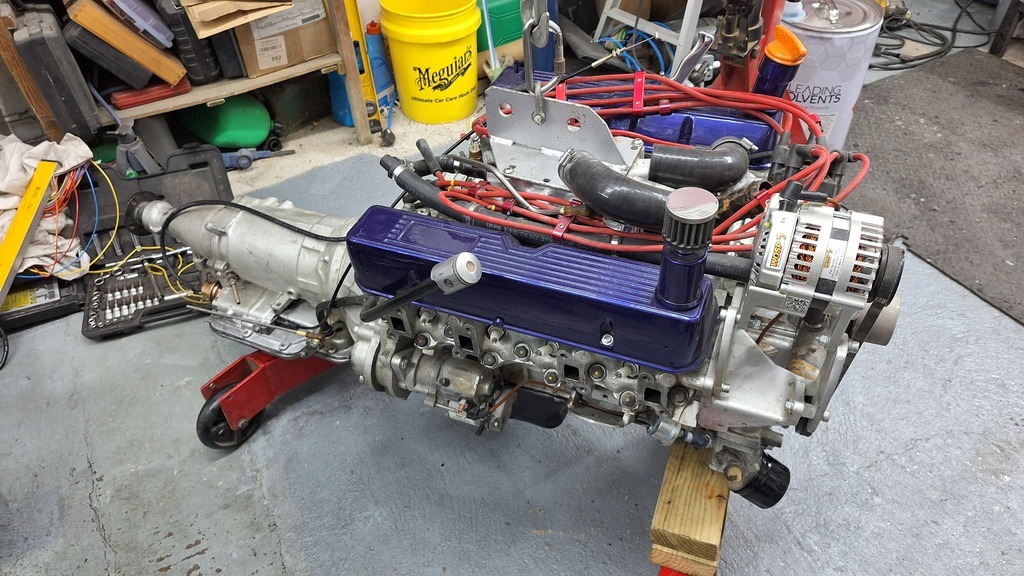

Had my dinner & carried on  After a bit of a tidy up and clean I started on the engine. I had been waiting for the engine & gearbox sump gaskets to arrive - they came today so it was time to address the mangled sump. For once this was not Car SOS's fault - I suspect someone in the past had jacked it up under the sump which had caved the side in where the oil drain plug is - so it would never fully drain the oil. Car SOS did have the sump off, so they could have fixed it like I am about to. Engine raised to a reasonable hieght to work on - it was lowered again after the sump came off.  As you can see, the side is kicked in badly.

Carefully heating it with the propane torch (I did not want to melt the braze) and putting a bar through the sump plug hole and levering it carefully saw it mostly flat again, some more heating and a BFH and a dolly got the bottom fairly flat as well.

The flanges were quite bad, a lot of hammer work was needed to get them all flat & level again, with the bolt hole edges dressed down with a ball bearing. The gasket is being bonded on overnight with gasket adhesive to stop it moving around, and will also be glued to the engine block.

|

| |

|

|

gazzam

Part of things

Posts: 747

|

|

|

|

|

Typically nice work, particularly on the brake lines.

|

| |

|

|

|

|

|

May 23, 2024 15:13:56 GMT

|

Typically nice work, particularly on the brake lines. Thanks! I always try to make the nice and straight with tidy bends, it's the little touches that add up so much (as you well know). |

| |

|

|

|

|

|

May 23, 2024 15:19:27 GMT

|

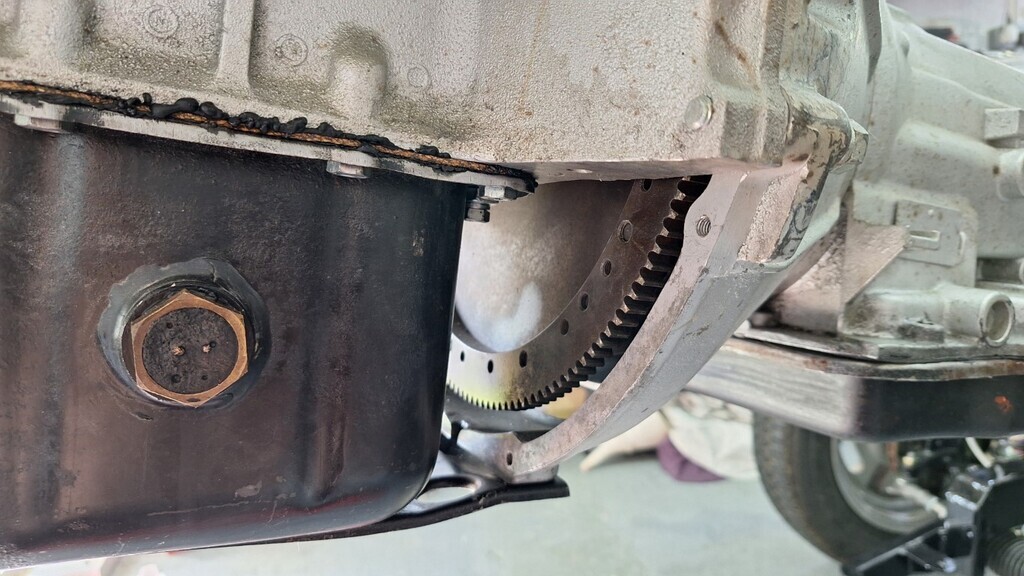

last nights progress was this.  It does not look much does it? Sump is now on for keeps and I spend a wonderful time taking the sump off the gearbox to access the kickdown cable fixing with the resulting mess that causes without a drain plug. Only to find (after a lot of internet searching) that the cable can be changed externally  Oh well, I cleaned the sump out and the servo housing, so its all spotless in there now. I'd guess that the gearbox was also overfilled, as I got over 4 litres out of it and the converter is still full. Recommended approx amount is 3.5 litres and overfilling it causes aeration of the fluid with the resultant wearing of the bands. This was the only evening so far where working on it was not a lot of fun. |

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

May 23, 2024 22:35:45 GMT

|

|

Where did you get the 3-way brake union with brake switch port? Is the brake switch port NPT?

|

| |

|

|

|

|

|

May 23, 2024 22:38:52 GMT

|

|

It was already on the car,but car builder solutions probably has them.not sure on the switch thread as I've not undone it.

|

| |

|

|

|

|

|

May 23, 2024 23:14:26 GMT

|

Andy & Kim came over tonight to drop the new paint off and also to have a look at the car. Andy is very happy  Seats. As previously mentioned the drivers seat is just too near the pedals and the seat adjuster sticks out so far it gets in the way of your feet. So........ the rear of the seat frame got chopped off and repositioned and very carefully welded back on again each side a bit further forwards. This involved a lot of careful clamping of my spark blankets around the frame to cover all of the seat material, tricky, but it all came out unscathed.  The seat runners were bolted to the floor with some 10mm nuts as 'spacers' to stop the adjuster being crushed into the carpet (which it still was). I found some 25x25x3mm wall tube in my stock bin and welded it to each end to raise the seat up enough for it to all work properly. The adjuster also lost about 4" of length. I've welded 2 bolts in as studs so far, but ran out of time for the other 2.

The end result is the drivers seat can now move back 4" more than before, which is much better for the pedal position, but the steering wheel is a bit of a reach (if seat is in the most rearward position). A deeper dish wheel or a spacer would remedy this though.  |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,885

Club RR Member Number: 39

|

|

|

|

|

Automec are my go to for brake parts.

|

| |

|

|

Enbloc

Part of things

Posts: 399

|

|

May 24, 2024 19:28:50 GMT

|

It was already on the car,but car builder solutions probably has them.not sure on the switch thread as I've not undone it. Thanks. I thought you had fitted it with the re-plumb. |

| |

|

|

|

|

|

May 24, 2024 22:19:04 GMT

|

I got a couple of hours in after work today. Seat is now painted - epoxy primer is almost the same colour as the paint on the seat frame. And a job I knew would be unpleasant, re-wrapping the headers. My arms really itch now, even after a long shower  I should have remembered to tape up my sleeves to the gloves. They are not the easiest headers to wrap, combined with using the wrap that they had torn and it being used made it twice as hard. I've exhausted* my stock of stainless wrap ties as well. They are now painted in high temp paint, partly to protect the wrap but also as it seals it up & reduces the fraying. Seat runners are also primed on the bare metal parts, ready for spraying tomorrow.

* see what I did there  |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Club RR Member Number: 77

|

|

May 24, 2024 23:02:13 GMT

|

What you did there, I see it  |

| |

|

|

|

|

|

May 25, 2024 21:14:27 GMT

|

well today was a little frustrating. It started well with the first job of painting the seat runners and a couple of other bits in satin black.  Then it was time to put the engine back in (not for keeps) to see how everything fits. Steering is tight for clearance but it all goes in ok. Steering is still remarkably light considering the engine is now back in there. But before the engine went back in I noticed the cover plate for the bellhousing was missing, so it got templated with cardboard;   Which will get made from 2mm ally next week. Once the engine was back in it was time to sort the shifter linkage. Some of you might remember I had made the bits for this some time back, but they needed final fettleing once the gearbox was back in its home. This took a couple of hours and ended up needing the gearbox selector arm shortening 5mm to match the shifter throw. With it all working nicely under the car it got tack welded together and then I got in the car to check it worked properly..........errr......no  its still pretty sloppy  Bumhats. Hmmm......have to think on that some. Off out tomorrow for a 140 mile cruise in mine, so will have to look at it again on Monday. |

| |

|

|

|

|

|

May 26, 2024 19:56:33 GMT

|

Back from the cruise today, 170 miles total. Some of it a bit wet, but overall mostly dry and a good day. A few photos from the trip;        Once I got home I got mrs Blackpop to move the shifter lever while I watched under the car, the new rod is flexing, so that is the issue. I've ordered some 8mm rod ends and will make a new linkage with 10mm tube and try to keep it as straight as possible. I've done a bit of research on the Rover shifter - I've ordered a new ball cup to take the slop out of it and when I dismantled Andy's one Car SOS had packed it out with washers to stop the safety detents from working, so it could be put in any gear just by knocking the shifter. This means it would have been possible for andy to knock it into reverse or park while driving down the road, a quick way of grenading the gearbox and possibly crashing the car. I've freed up the mechanism and with a new press button knob fitted it will have the safety lock back - you can only shift gears by depressing the safety knob. A friend with mills & lathes had offered any machining required, so I've asked if he can make a new shifter knob for us. |

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,240

|

|

May 26, 2024 22:09:04 GMT

|

Nice pics, some really cool cars  Left side, is that a 32 Ford ? |

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

May 27, 2024 17:09:34 GMT

|

|

That is a '32 Ford, but an English bodied one, with suicide doors and some other differences.

|

| |

|

|

jimi

Club Retro Rides Member

Posts: 2,240

|

|

May 27, 2024 19:26:08 GMT

|

That is a '32 Ford, but an English bodied one, with suicide doors and some other differences. Model B or 18 ? either way it's super cool, like it a lot  |

| |

Black is not a colour ! .... Its the absence of colour

|

|

|

|

|

May 27, 2024 22:53:22 GMT

|

well after yesterdays day out it was maintainance time for mine. I only have 8 days to get it ready for the Hot rods n Hills weekend  and I've not done anything on it for a very long time. It's developed a really annoying squeak recently, and even more annoying I can't even trace where in the car its coming from. *I did find later the bootlid hinge has been chafing the ally panel so this 'might' be the squeak. But also I needed to grease the rear suspension bushings and generally check it all over.  The urethane bushings were all slightly worn, so I put a new set in as I had a load of spare ones, I also replaced the steel sleeves with some stainless ones I had made years ago. With all of the bolts cleaned up and everything greased it got reassembled. The rear shocks came off and I cleaned up the ally and put them on the polishing mop to shine them up again and also the polishing wax protects them for a good while. I spend a good amount of time washing the underside of the car, and touching in some little areas of rust where bits have got chipped. 12,000 miles has taken its toll ands it's not quite the mint condition of when it was built anymore. Another job while the suspension arms were off was to torch the seized bolts in the wheelie bar mounts, I normally grease up all the bolts, I'm not sure if I forgot last time on these ones or whether they just got rusty anyway, but they had refused to budge with a 6ft pole on them and even a month of penetrating oil had no effect. 3 minutes with the propane torch had them free though  I have to admire 2 pack paint, torching them did not seem to hurt the paint at all? (not that it was in great shape). New mounts are starting to get made - basic plates cut so far (old ones in background) as the old ones were modified after one of them fractured and ended up busier than I had planned (they originally had the single plate holding the tube & I had to add the extra side plates after the middle 6mm plate fractured). The new ones will be smaller and stronger with the double 6mm side plates.

|

| |

|

|

I used a bit of the old pipe to make a trial section for the take off for the front brakes, which is the loose bit at the bottom of the photo, should make that section a little easier to make tonight.

I used a bit of the old pipe to make a trial section for the take off for the front brakes, which is the loose bit at the bottom of the photo, should make that section a little easier to make tonight. I used a bit of the old pipe to make a trial section for the take off for the front brakes, which is the loose bit at the bottom of the photo, should make that section a little easier to make tonight.

I used a bit of the old pipe to make a trial section for the take off for the front brakes, which is the loose bit at the bottom of the photo, should make that section a little easier to make tonight.

I should have remembered to tape up my sleeves to the gloves.

I should have remembered to tape up my sleeves to the gloves.

and I've not done anything on it for a very long time.

and I've not done anything on it for a very long time.