Another glorious summer weekend. I wonder what the weather will be like?

Oh. I’ll be getting get the tent out then.

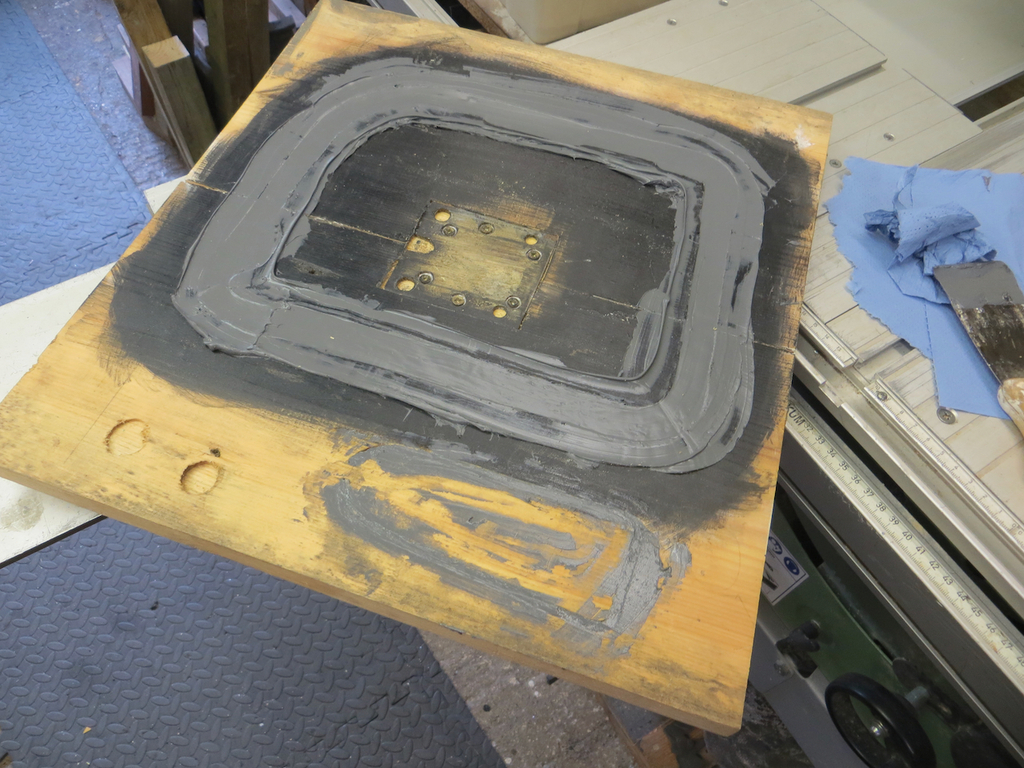

The first job is to seam seal all the joints.

Round the boot lid it didn’t look quite as pretty.

In fact it looked horrible but I cleaned it up after I took the photo and it looks a lot nicer now. I hate seam sealer. I don’t seem to have the knack of putting it on nicely without dragging it all over the place.

I even did inside the boot.

After that had dried I got the spray gun out and blew a bit of black paint on the inside of the panels. I said to myself that the last thing I should do is forget to take a photo of that. So the last thing I did was forget to take a photo of it.

In an attempt to stop it all rusting away from the inside again I attacked it with a tin of cavity wax. God that stuff stinks. I hope the smell fades after a while.

Then I had a problem because I was missing that bit from the B pillar. Not a huge problem because I could just make another bit. However I also realised that I was missing a load of trim from the rear quarter light, some bits from the fuel tank, parts of the body work from near the engine cover and, most worryingly, the quarter light glass.

Hmmmm. They are in a box somewhere at Sweetpea Towers. Anyway, after an hour or three of hunting they turned up in the loft of the West Wing.

Thankfully the missing bit of the B pillar was there too.

Excellent, those hours of hunting saved me 20 mins of metal bashing…

I really didn’t need much of it.

Welding it in did, as suspected, turn out to be a bit of a git because I couldn’t clean the back side of the panel so I was getting curse word contaminating the weld.

When that happens it’s pointless putting more weld on top. The only solution is to grind it flat which, hopefully, that takes the contamination away. Then try again. You do go round in a circle some times.

Anyway, after a bit of messing I got a decent weld and slapped some primer on to protect it.

Good. Onto the next job.

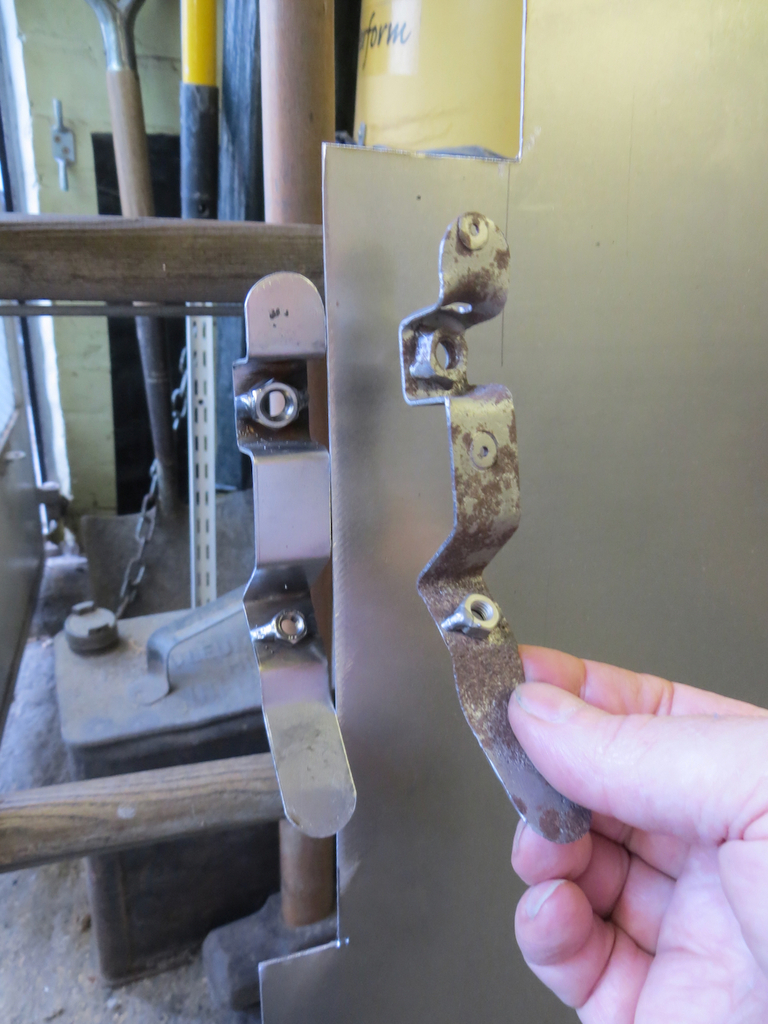

The next job is that bracket from the bottom of the car which I had cleaned up and then went rusty again. What I really should do is make a new one but to be quite honest I couldn’t really be bothered.

In the past I have found a correctly shaped and sized patch in the scrap bin just by pure coincidence. So I thought I’d look and see if there was a bracket shaped thing in there. Well of course there wasn’t. That sort of thing doesn’t happen in real life.

But as luck would have it I glanced at the bit of steel sheet that I use to make patches and, well, there it was. A completely identical piece in the edge of the sheet.

What?

You can’t see it?

It’s there in the blue marked part of the sheet.

Aw, come on…

You might need to squint a bit…

Ok, look, let me flip the bracket round and turn on squint mode on the camera.

There, see it now?

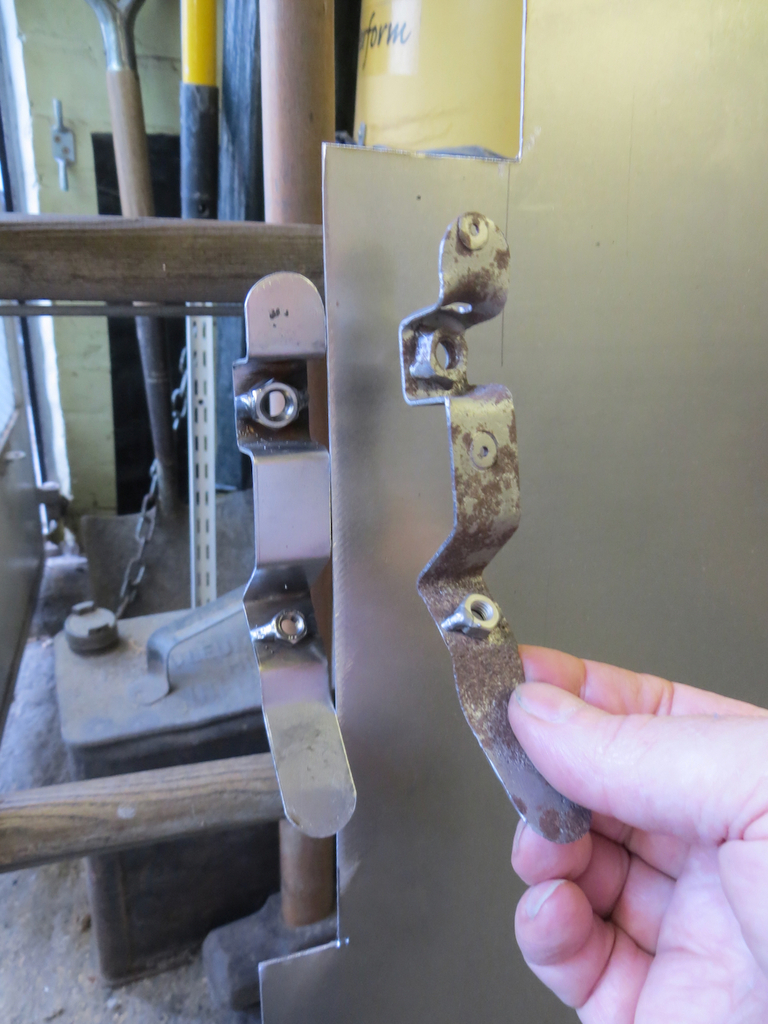

When I offered it up against the car it didn’t quite fit. The bolt hole in the pipe work wouldn’t line up with the nut on the bracket I’d found. It turned out that I was missing a hole in the top of it. So I made one and then it fitted together.

I had assumed that the hole was used when they welded the nut on the original and that I didn’t need it. Well, no. That was wrong…

The bracket holds cooling pipes that run the length of the car. The pipes have a little hook on them that drops into the hole. When they built the cars the chap could hook the pipes on the brackets and then go and get the bolts to fasten it on. It means they didn’t need two people or several arms to do the job. One little hole and a hook probably saved a good deal of annoyance or an extra person on the production line.

I expect other manufacturers were doing this sort of thing back in the ‘80s but I can’t help being a bit impressed that Toyota designed it this way just to make it easier and more efficient for the factory to build it. It shows an attention to detail that I hadn’t imagined.

Anyway, once I’d added the appropriate hole it all fitted together so I welded it up.

And then I got the epoxy primer out and gave it all a paint.

You probably haven’t realised but although the wing isn’t painted and clear coated the wing is now fully fitted to the car. In fact the only thing that means the car isn’t water tight is that the quarter light isn’t fitted.

I can’t fit the quarter light because it’s glued into the hole with a butyl tape and I need all the paintwork done before I can glue it in.

If only I had some sort of temporary window that I could install and remove at will then I wouldn’t need that bloody car cover that I keep sticking my fingers through every time I touch it.

Oh! Look what turned up in the scrap bin!

Ace! No more car cover for me! Yay!

Do you think the car is actually water tight???

James