|

|

|

|

|

Well Ive not spent as much time working on this as I was planning this weekend just gone. In fact I did nothing to it on Saturday. This morning I woke up to snow on the mountains around us. It never really warmed up and felt like what a proper cold winter day should be like.  However I managed to get enough done today worthy of an update. First off I finished the passenger side repairs. I had to put the car up on hoist so I could shift a Volvo under it. Was quite nice standing up to do these last outer skins. Since it was up in the air I repaired that hole on the inner sill which meant I was able to paint epoxy on the entire inside before welding a new skin in place. I wont grind the last welds down because well, I just cant be bothered right now as its boring grinding. I might just paint them over in primer to go along with the rest of the fancy paint job the car currently wears.  I know not what could possibly be under this lumpy looking skin but it feels crunchy. I think I will leave that till later...  I put the car back on its feet and shuffled it over to attack the other side.  Its not as bad on the inside floorpan. Just a couple of areas that need cutting out.  However the outer sill...mmmmm. Yeah pretty shot although with the squeeze test it feels like the bottom might be ok. Will find out soon.  Good news. I found some more money. This can help offset the purchase price of the car..  So into it then. First off I cut out the rotten area around the drain. It would be easy to just weld in a square of steel and be done but I want the floors to drain as they should so I had to make a go at replicating what I cut out. Hole sawed a hole into a piece of 1mm thick steel quite a bit bigger than needed and then using a bit of pipe and a piece of round solid about the right size I formed the step in the vice.   Turned out good and I was a happy chappy. I had to form one corner to suit the two channels and then cut the square to size.  Welded it in and ground down the welds where the channels enter.  I'll finish the floor and then cut open the sill. Oooooh I cant wait! ...its going to be like a really s--t Kinder surprise isn't it. |

| |

Last Edit: Aug 9, 2015 10:06:57 GMT by yoeddynz

|

|

|

|

|

|

|

|

|

Hi Alex. You are truly a miracle worker. Looking at this makes we realise that my Wolseley is not as bad as I first thought when I started poking it with a big screwdriver and the holes kept getting bigger in places that looked like they didn't even have holes. I'd love to have even half the welding skills you have. Hey cheers but I have just learned all this through trial and error. I think that the best way to learn and practice is just welding up old rusty cars :-) Best thing to do is buy a nice little mig and gas bottle then just get into it. A grinder will be your best friend. Start on areas that wont be seen and by the time you hit areas that can be seen hopefully your welding will have improved :-) |

| |

|

|

|

|

|

|

|

fairly certain those holes in the floor pan were just to let the paint out when they were dipped at the factory. not to undermine your work obviously, just pointing out the ironic attention to detail for a non essential hole  agree with you though, theyve come in handy quite a few times on the "kadetts" |

| |

Last Edit: Aug 9, 2015 10:11:40 GMT by darrenh

|

|

|

|

|

|

|

|

Thanks for the good advice. Best way to learn anything is have a go for sure. I've only ever used Oxy-Acetylene and not even that in the last twenty years. I keep promising myself a mig or even a cheap arc welder but the money is never there.

|

| |

|

|

|

|

|

|

|

|

Ooooh I wouldnt want to try welding thin panel steel with a stick welder. But oxy acetylene is good especially with rusty steel however I think its easy to get panel warping if used on long runs/flat panels.

Darrenh- yeah I think you're right there. Plus I think the little square covers held in place in the kick panels are for the same thing. But because this car is British plus it currently has terrible seals it will be quite handy to have the holes there. It want really too mush hassle to add it back in.

|

| |

|

|

|

|

|

|

|

I made more progress on this today. No interruptions. Just me, music, coffee, welder, grinder. First off. I spotted this little fella making a go at life in the side window seal. I like it there and will try to nurture it along.  Back to rust. This looks a slight iffy..  Yep.  I'm loving this perfectly shaped wing. I shall keep that as is. Someone has put a lot of effort into creating that.  So I cut out the sill and this was inside...  I have kept it all and can sell it on to someone who needs an original sill for a future build..  Luckily the front end of the outer sill was solid so that stayed in place so keeping a nice datum point to weld to. Inside the sill it was all really pretty good. Just needed a wirebrush and some paint. Again, much like the other side, it was foolish to attempt to use the very bottom of the inner sill so I chopped it off and welded in fresh steel. I also had to re-make two sections along the top of the sill structure that were just a bit too iffy to use.  I then folded up two more sill sections to suit.  Painted the inside and then welded them in place. I then chopped out the rear end rot areas.  Much better condition at the very end on this side. Good :-) Just two patches but I ended up doing the larger one right back to the bottom edge because it took no longer and means the whole sill bottom along there is new. Pinted and welded up. Its now looking like a proper patch work quilt :-)  I finished tonights effort by welding up the last section in the floor.  There was an area that was a touch too thin.. I think there will be little hedgehogs sticking out out through the underside..  Then I swept up and moved the car onto the hoist. Next area is the bottom of the a post/sill end which luckily is not too bad.  Once that is done I can attack the rotten chassi rail/rails. So far it seems to be that only the drivers side is rotten but I will find out soon. I need to buy more sheet steel though and will get some good thick stuff for the rails while I am at it.  |

| |

|

|

MK2VR6

Posted a lot

Mk2 Golf GTi 90 Spec

Mk2 Golf GTi 90 Spec

Posts: 3,329

|

|

Aug 11, 2015 11:53:37 GMT

|

Interesting approach on the patina, but genuine is always better than fake, I guess  I keep spotting HBs for sale here in the UK and continue to be surprised just how far behind Mk1 Escorts their values remain. They definitely seem to be on the up, but haven't gone mental...yet... |

| |

|

|

|

|

|

Aug 11, 2015 11:56:30 GMT

|

|

One day....one day. But for now yeah they are still very cheap. Over looked classic imo.

|

| |

|

|

|

|

|

Sept 18, 2015 8:04:24 GMT

|

I'm back! Well I was always around but on one night a couple of weeks ago A cold sneaked up behind me, threw a sack over my head and dragged me off to a place where I did not want to do anything but sniff and feel yucky. This was just after having been busy fixing other peoples cars for that money thing. Basically put.. my roll had stopped rolling and this wagon stayed up on blocks. But yesterday I got my rust mojo back and got stuck back in. The wagon has been sharing the workshop for the last few weeks with a cool old Volvo 145, a very bright Saab 95, Bimmer 320 plus Hannahs Trump Mk1 wag. I do like lifting the door to see intersting cars in there :-)  Not too much to show because it was all slow repairs around the chassis rails and jacking points which I want to really make sure is nice and solid. I have now just earlier finished the worst of this area with not much to go. I used a combination of 1.6mm steel and a very handy piece of box section that happens to be the correct width and thickness. This has been saving my folder from trying to fold 1.6 too often- it being really only designed to fold up to 1.2mm. Luckily the rust has been along the bottom of the rails where the damp has sat thus leaving the uppers attached to the floor nice and strong. I remade the gearbox mounting brackets and made them semi fixed with an extra bolt rather then the little tabs that Vauxhall had fitted, now rusted away.  As I have been working my way along the rails I have sprayed the insides of the new steel with zinc rich paint. Later on it will get a heavy dosing of wax. So the last very interesting photo for this mega update is of the underside sort of almost rot free.  I promise I will try to do better next time although I most likely will just take more photos of rust. I am very much looking forward to the mechanical/bodging/fiddling/tweeking updates when I get the car moving and stopping. I have been having many day dreams whilst chilling in the sun under the influence of man flu about what I could do with the engine/what I could swap it with. I still love the absurdity of a grand plan I dream about where I squeeze a BMW V12 with a manual box in place :-) However I usually come back down from cloud nine and mull over more realistic propositions such as a sneaky carb fed turbo, perhaps a Datsun engine or maybe fit fuel injection from another 1200cc car (that last one more for the technical fun in doing so rather than any real benefits it most likely wouldn't really bring) For now though it has to be rust removal. |

| |

|

|

smeden

Part of things

"Full throttle until you see God,then shift to second"

"Full throttle until you see God,then shift to second"

Posts: 356

|

|

Sept 18, 2015 8:59:48 GMT

|

|

lovly work! Nice to see! I fitted fuel injection on my car! From a later model. I did give me some real bebefits! (and a lot of headache too) But it was well worth it. Find something with a monopoint injection. That could work out.

|

| |

Jaguar xj6 S1 swb manual

VW Bay Camper

Audi A3 1998 1.8

VW Beach Buggy (sold)

Ford Mondeo mrk I RS Celebration (written off)

Ford Escort Mrk II RS 2000 (rust in peace)

|

|

|

|

|

|

|

Sept 18, 2015 11:40:35 GMT

|

|

Yeah I was wondering about something like the single point injected mitsi's etc? I figure if it has closed loop control it'll constantly tweek itself to compensate for slight differences in engine characteristics. Maybe the injection off a mini as they too have Siamesed ports like the viva engine ?

|

| |

Last Edit: Sept 18, 2015 11:40:58 GMT by yoeddynz

|

|

|

|

|

Sept 18, 2015 13:49:06 GMT

|

|

For engine swapping how about something from the slightly newer range of Vauxhall/Opel/GM cars from the late 80's early 90's which have fuel injection.

I suppose this assumes that these age engines and the ancillaries are easy to come by in your neck of the woods , which may not be the case.

You have your perennial favourite of the 2.0 16v C20XE engine , which have been made to fit into Manta's , so your Viva shouldn't be too different or you could go with the 2.0 8v lump C20SEH engines with lots of low down torque.

Joff

|

| |

|

|

|

|

|

Sept 18, 2015 20:44:31 GMT

|

|

Yep- the above engines you mentioned are not easily available about in NZ.

Just thinking about a little bit of extra pep. Datsun engine with around 70-80 bhp would be more than enough to make it a very useful daily hack, which is what I plan to use it for to start with. A beat up old load lugger :-)

In NZ you are allowed to complete an engine swap without the need for an engineers certification if you follow these rules;

No increase in capacity,

an increase in power of no more than 20%,

engine has to pretty much bolt in using factory mounts with no cutting or welding.

So I either keep it stock, turbo it, inject it or fit a Datsun engine which do apparently slot in nicely.

Otherwise if I need to cert it I might as well go balls out and fit a V12 :-8 ! (or I still like the idea of a Saab engine)

|

| |

Last Edit: Sept 18, 2015 20:45:44 GMT by yoeddynz

|

|

kilroy

Part of things

Suit you sir...

Suit you sir...

Posts: 251

|

|

Sept 19, 2015 9:31:00 GMT

|

|

Alex

I know its old hat - but what about a CF Bedford 2.3..?

They are related - and can be made to elicit some formidable horsepower - just with carbs.

Mounts possibly similar as they were fitted to Magnums and Firenzas.

FTW.!

|

| |

|

|

|

|

|

Sept 19, 2015 20:40:35 GMT

|

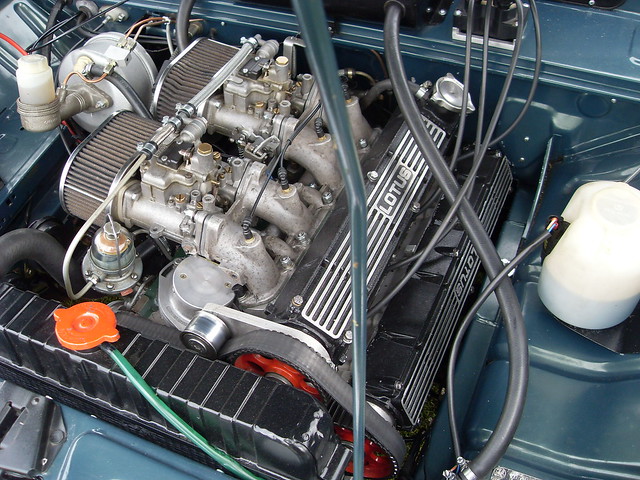

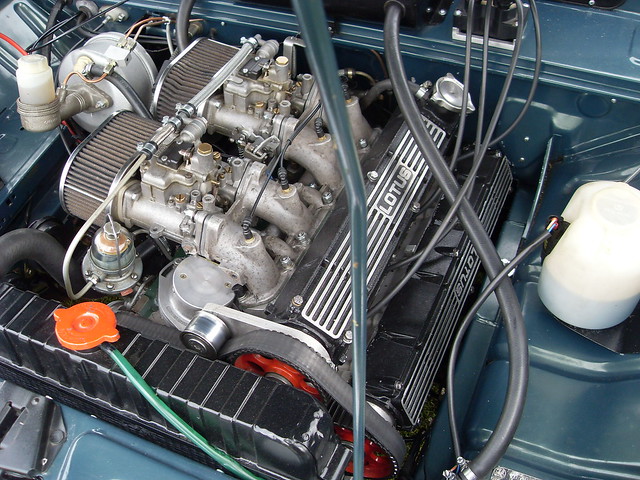

Hello Ken. The old 2.3 eh? Hmmmm..Not only old hat but also a...  I've had a chevette with one and they really do ruin the handling of little cars with all that weight out front. Then there's the terrible oil pump location, lack of easily located 5 speed boxes, tight space for exhaust headers. Nup..  Next please :-) I do fancy a lotus twink though- like what Paul Bottemly has fitted to his HB. Lovely looking engine with I think a toyota bellhousing pattern? |

| |

|

|

|

|

|

Sept 19, 2015 20:59:59 GMT

|

Fantastic to see some progress on this! The Lotus 907? The bosses on the inlet manifolds were allegedly for factory injection which was never realised (bean counters said 'no' ??) Just saying . . . . !  |

| |

|

|

|

|

|

Sept 19, 2015 21:51:07 GMT

|

|

Rover V8 if its got to be certified at least its nice and light? What about a small turbo diesel swap or are the RUC's making it not worthwhile anymore?

|

| |

|

|

|

|

|

Sept 20, 2015 7:05:35 GMT

|

|

RV8 such old expensive engines nowadays. more expensive than so many better V8s out there.

but they do sound nice!

|

| |

|

|

kilroy

Part of things

Suit you sir...

Suit you sir...

Posts: 251

|

|

Sept 20, 2015 9:11:30 GMT

|

Lotus is sure classy - and carbs for that instant response win - but lotsa dosh for the bits. Anything else from the old country interest you sir.? Just to preserve the parentage you know...  |

| |

|

|

smeden

Part of things

"Full throttle until you see God,then shift to second"

"Full throttle until you see God,then shift to second"

Posts: 356

|

|

Sept 20, 2015 10:42:37 GMT

|

|

Mazda Miata mx5/miata engine and box..

|

| |

Jaguar xj6 S1 swb manual

VW Bay Camper

Audi A3 1998 1.8

VW Beach Buggy (sold)

Ford Mondeo mrk I RS Celebration (written off)

Ford Escort Mrk II RS 2000 (rust in peace)

|

|

|

|

agree with you though, theyve come in handy quite a few times on the "kadetts"

agree with you though, theyve come in handy quite a few times on the "kadetts"