|

|

|

Feb 15, 2024 11:34:20 GMT

|

|

That's a tidy wiper motor swap. I don't know how different the escort is to the Cortina but there's a column support behind the dash binnacle on the mk1 cortina that was right in the way of the Volvo Bosch motor I used so I had to rotate the motor 10degrees from 12 o clockl. Just thought I'd mention it if you wanted to copy that for your mk2

Edit: I managed to wire 1 and 2 speeds in fine but never managed to sort the intermittent or wash wipe (it seems to do 1 rotation, park, then go again) If you want the wiring diagram I made I'll fire it over to you

|

| |

Last Edit: Feb 15, 2024 11:36:26 GMT by jim

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

|

|

Feb 17, 2024 18:16:41 GMT

|

That's a tidy wiper motor swap. I don't know how different the escort is to the Cortina but there's a column support behind the dash binnacle on the mk1 cortina that was right in the way of the Volvo Bosch motor I used so I had to rotate the motor 10degrees from 12 o clockl. Just thought I'd mention it if you wanted to copy that for your mk2 Edit: I managed to wire 1 and 2 speeds in fine but never managed to sort the intermittent or wash wipe (it seems to do 1 rotation, park, then go again) If you want the wiring diagram I made I'll fire it over to you Thanks for the info Jim. I doubt I’ll change the motor on the Cortina. It doesn’t get used enough in the dry, never mind in the wet😁. I’m putting the Mazda stalks on the Escort too. When you’re strapped in it is a pain to reach the switch on the dish. The bonus is the Mazda stalks have the relays for the intermittent in them, which makes wiring a doddle. Just give he stalks 12v. I’ve not checked if the motor fowls anything yet but hopefully it won’t be to much of an issue |

| |

Last Edit: Feb 17, 2024 18:18:21 GMT by jonsey

|

|

|

|

|

Feb 17, 2024 18:31:30 GMT

|

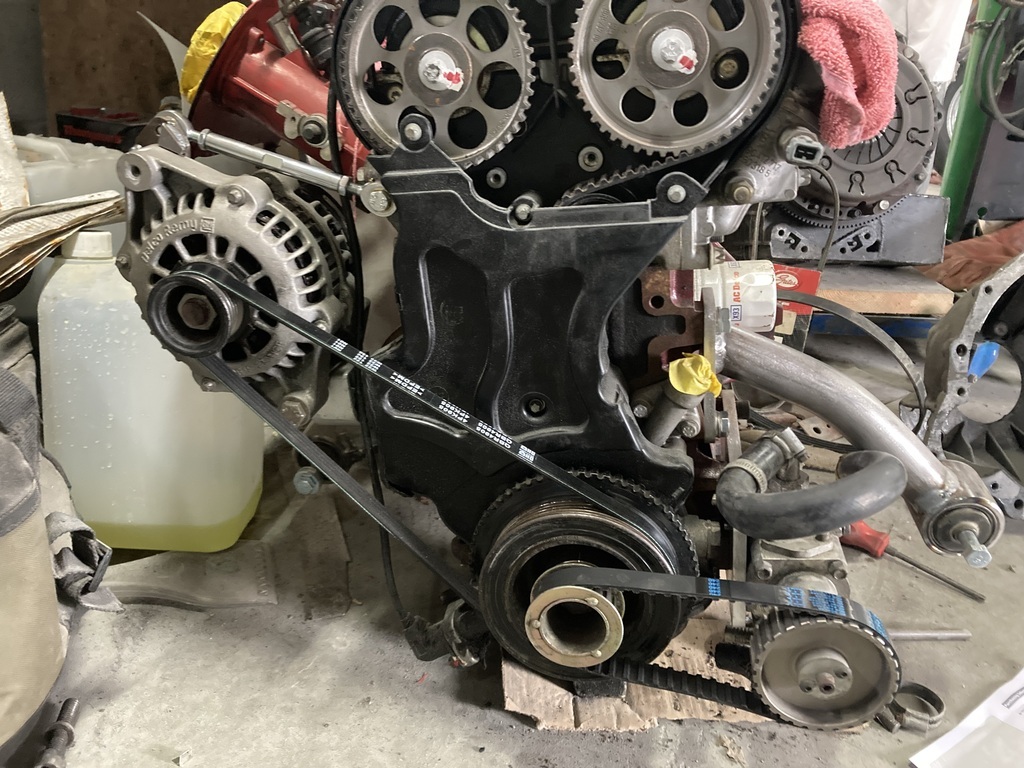

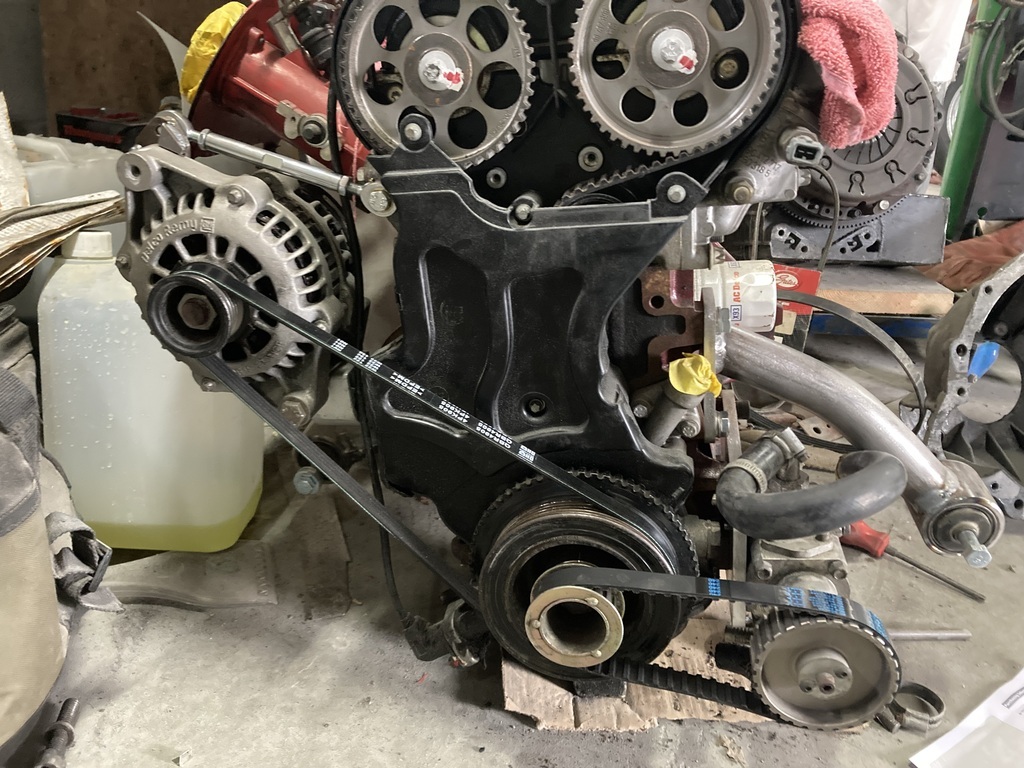

Dry sump pump continued. My nephew has used some witchcraft to produce some plastic parts. A spacer to move the crank pump drive out past the alternator pulley. And a plate to move the dry sump pump forward by the same amount    And all mocked up.  He has also made me a drill jig to mark the holes in a new bit of aluminum plate  These fit a treat, so I can now make the aluminum plate and Sean is going to get his mate to CNC the crank spacer. It’s all magic |

| |

|

|

|

|

|

Feb 22, 2024 12:09:49 GMT

|

Another call shift, another couple of hours done. I had bought a 6”x6” piece of aluminum plate that was slightly thicker than the original at 9.5mm. Using the drill guide, I used a 3mm drill to get a pilot in each hole. Then a drilled the mounting holes to the engine to 10.5 and chamfered for the counter sunk bolts. Next I drilled the pump mount holes out to 5mm. These were then taped to 1/4unc. Everything was going great until I snapped the tap in the last hole. We tried welding on a nut to wind it out but the tap just broke up. So as needs must, I used a drift to knock the tap out, used the countersink bit on both sides of the plate, welded up the hole and finally (after getting a new tap from eBay) tapped the last hole. No photos of any of this, but here it is completed.  I could then try it on the engine  And finally mount the oil pump  Sorted. The pulley spacer turned up too  And Sean has also 3D printed a couple of bits for me to both drill the 2 roll pin holes in the crank pulley and at the same time move the “space” in the trigger wheel by the required 11°, to match the race car trigger wheel.  |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,126

|

|

Feb 22, 2024 19:49:27 GMT

|

|

Snapped taps are a nuisance.

|

| |

|

|

|

|

|

Feb 22, 2024 22:47:17 GMT

|

Snapped taps are a nuisance. It did raise my temperature a tad😡 |

| |

|

|

|

|

|

|

|

So, a few bits and bobs from the last couple of visits to the garage. Sean’s drilling guide was used to sort the new locations for the pulley roll pins, an 4.7mm bit used to drill them out. And the slot made bigger to avoid the key way on the cam belt pulley.   So the roll pins could be refitted along with the alternator pulley, new spacer and dry sump pulley.  The turn buckle tensioner I bought did not fit as it hit the alternator before lining up with the bolt hole. I used a bit of 8mm plate that bolts to the alternator to lift the mounting point a tad and the adjuster now fits.  This means I could now measure up for a belt. I cut an old shorter belt, pulled it tight on the pulleys and used a ruler to measure the gap. 913mm was my first choice. Lots of slack and only tightened with the turnbuckle at max length. So I tried a 900mm and that was to tight. Couldn’t even get it over the pulley, the Goldilocks length was 905mm that fitted just right.  Thanks goes to the young gentleman on here with 4door mk2 Escort with MX5 engine (His name escapes me now). He works in my local motor factors and ordered the right size in for me. In other news, I’m struggling to sort a clutch cover. My flywheel is flat. I ordered a kit for a Tigra as that is what I believe the engine is from, and the cover that arrived is for a recessed flywheel. So that needs to go back. |

| |

|

|

|

|

|

Mar 16, 2024 16:45:45 GMT

|

It’s been a couple of weeks since I’ve done anything out the garage. Work, life, the boys doing a motorkhana in the MGZR are all to blame. So today after a quick shopping trip with Mrs Jonsey to get some lights for the shepherd’s hut, I managed to get a few hours in. After the struggle to get the correct clutch cover, I managed to get the right one. The flywheel is in fact a 14xe item and not a 16xe. Apparently a popular mod as it is lighter.  So armed with my shiny new paddle clutch and an old gearbox input shaft,  the cover got fitted to the flywheel.  The 5mm spacer plate got welded to the Westfield bellhousing.   It’s only tacked on for location. The bolts actually hold it in place. I then fitted the clutch fork and release bearing  This is so I could check if there is free play between the realease bearing and clutch fingers. I don’t have the correct Westfield fork. This is a Sierra item I modified years ago with a mk3 Cortina bearing. So was unsure if it would work. Luckily it did and I’ve got 5mm free play  All bolted up.  While I remembered, I cut off the bit of the engine block around the starter as it was close to the steering shaft.  There is still plenty of meat left. Tomorrow I’ll take the bellhousing back off as I need to convert it to quick release. |

| |

|

|

|

|

|

Mar 17, 2024 19:58:24 GMT

|

So today’s task is to make the bell hosing “quick release”. Usually, the bell housing is attached to the type 9 gearbox with 4x m12 bolts from the bellhousing, through into the front of the gearbox. With a quick release bellhousing, it is mounted with bolts from the gearbox, into the bellhousing. This means you can now leave the bell housing attached to the engine and remove the gearbox on its own. In a rally, this should speed up a gearbox change. I want this system as I think it may be easier to fit the bell housing and box separately. The blank holes that the bolts usually go through to thread into the gearbox  Threaded bosses that need to be fitted into these holes after they’ve been drilled out to 14mm  I had to grind some of the shoulders off the inserts to get them to fit  The inserts are then drilled and roll pinned to the bell housing to stop them falling out / turning.  See that hole in the centre. The selector shaft protrudes into that hole so it has to be oil tight when fitted. There is a gasket between the bell housing and box to seal it. I took the bell housing over my brother’s to drill the holes to 14mm. My brother pointed out that the oil is now going to come out of the gap between the bellhousing and 5mm spacer plate that I welded on yesterday 😡  So to seal this gap, I used a counter sink bit to open the hole up past the gap  I then welded the gap up  Next I filled the rest of the counter sink  And finally ground it back and burred out the hole.  I had to tickle the gearbox casing with the power file to get the bolts to fit in from the other side.   You can see that the bolt has not tightened up all the way. This is because the casing is not flat, holding the bolt off. I’ve borrowed a pointy burr to remove this next time I’m out the garage. |

| |

|

|

|

|

|

Mar 18, 2024 10:49:43 GMT

|

|

That's a cool modification to the gearbox

|

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

Mar 18, 2024 16:56:47 GMT

|

That's a cool modification to the gearbox Thanks Jim. Whether or not it’s any quicker to remove, remains to be seen. |

| |

|

|

|

|

|

Mar 18, 2024 22:06:41 GMT

|

|

I remember watching a crew change a similar one on a mk2 escort in a late 80's RAC somewhere near Swanasea, took them about 10 minutes!

|

| |

|

|

|

|

|

Mar 19, 2024 18:55:40 GMT

|

I remember watching a crew change a similar one on a mk2 escort in a late 80's RAC somewhere near Swanasea, took them about 10 minutes! I’m only about 13 miles from Swansea. Perhaps they can come and do mine 😁 |

| |

|

|

|

|

|

Mar 20, 2024 21:46:49 GMT

|

|

When I converted my gearbox case’s into quick release I used a 19mm reverse counterbore and used a battery drill rather than a mill so I had very little set up time, rather than try and explain what it is and how it works just google reverse counterbore it’s possible that you might not have come across this unless you know someone who works in the aircraft industry HTH

|

| |

|

|

|

|

|

Mar 21, 2024 10:14:42 GMT

|

When I converted my gearbox case’s into quick release I used a 19mm reverse counterbore and used a battery drill rather than a mill so I had very little set up time, rather than try and explain what it is and how it works just google reverse counterbore it’s possible that you might not have come across this unless you know someone who works in the aircraft industry HTH Never seen one of those tools before, but it’s a cracking idea. I’ve got a few cutting tips so I’ll see I can knock something up. |

| |

|

|

|

|

|

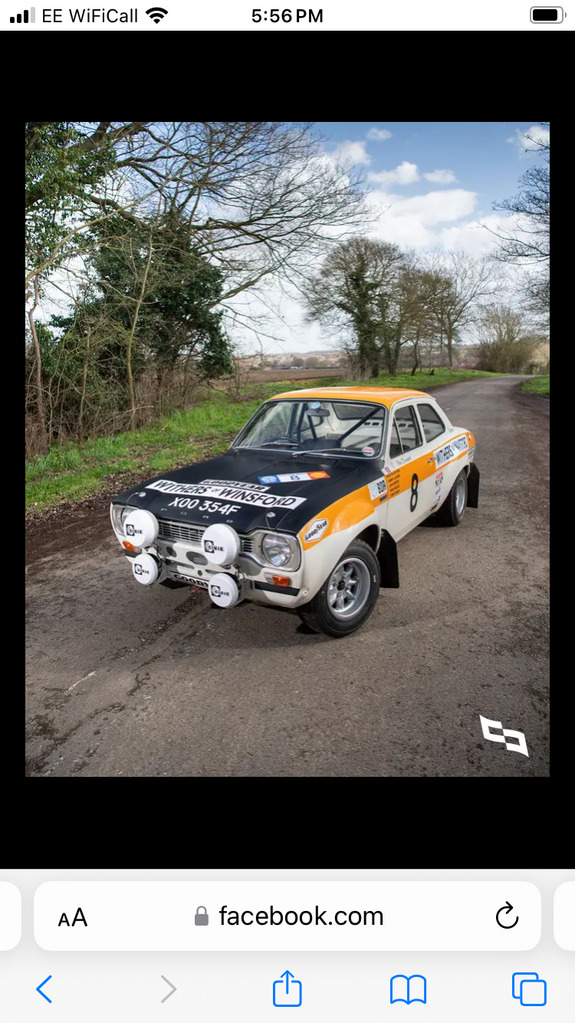

Mar 21, 2024 21:13:22 GMT

|

|

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,362

Club RR Member Number: 64

|

|

Mar 21, 2024 21:40:30 GMT

|

|

I think the stripe would look better.

You’re not going to want to compete in it once you’re done.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

I think the stripe would look better. You’re not going to want to compete in it once you’re done. 👍It is far too good for what it needs to be Glen, and this was done to my budget. They normally go a lot further than this. |

| |

|

|

|

|

|

Mar 22, 2024 11:32:34 GMT

|

|

I think you should stop rallying this……I fear panel gaps,rear quarter alignment and roof gravel rash,time to put the GTE to work 😁

|

| |

|

|

|

|

|

Mar 22, 2024 16:40:04 GMT

|

I think you should stop rallying this……I fear panel gaps,rear quarter alignment and roof gravel rash,time to put the GTE to work 😁 It’s a rally car so I’ll be used and it will no doubt get some more scars. The Astra isn’t mine so it’s out of the question |

| |

|

|