merryck

Club Retro Rides Member

Posts: 480

Club RR Member Number: 9

|

Learning how to machinemerryck

@merryck

Club Retro Rides Member 9

|

|

|

|

Hi all,

I've taught myself to weld (mig) and taught myself to fix cars (classic) but would like to learn a bit more about how to make things. I've been watching Youtube videos of people making bits here and there for years. I finally bought myself a pillar drill so I can now drill holes straight (baby steps!) but was wondering if there are any resources to learn how to machine?

I think we've all read through a johnnybravo thread and thought to ourselves 'Man, I wish I could make things like that'. I just don't know where to start. I can't afford to buy the gear, I can't afford to go to college/take an apprenticeship. Is there another way to learn this stuff?

How has everyone else learnt/taught themselves?

|

| |

|

|

|

|

|

|

|

|

|

|

It often helps if you have a friend or relative who is an engineer. My friend's father-in-law is a former engineer and he is always happy to offer advice or to show my friend how to do stuff. My Uncle is a former naval engineer and has a workshop to die for. He's got not one, but 3 lathes. He's offered to show me how to use them as well. Unfortunately he's 6 hours' drive away so time with him is limited...

|

| |

|

|

|

|

|

|

|

|

Years ago I did a 3 month evening course at a local college and they were happy to teach machining...But I did learn a lot at school doing "O" level metalwork.....yes I am that old!

Another thought - is there a local "Society of Model Engineers" or similar near to you? Also many heritage railways now have useful machine shops and I'm sure would help you to learn in exchange for some unskilled work from you.

|

| |

|

|

tonup

Part of things

Posts: 39

|

|

|

|

|

Look for your local 'Men in sheds' group. Some have lathes and stuff. Many helpfull people there too.

|

| |

|

|

|

|

|

|

|

|

The only way will be if you know someone willing to show you who somehow has access to all the gear . In all honesty its a skill and practise that you cannot just pick up or dabble in . You have to be taught and work slowly or you can really really have a bad day and hurt yourself - and its also easy to damage expensive tools and even the machines .

Even after many hours you will not be making fancy bits of any use like johnny . If you want bits made for your car its far easier and cheaper to do a drawing and send it off to be made somewhere .

|

| |

|

|

|

|

|

|

|

I think access to the machines is the biggest hurdle here. When I did my engineering apprenticeship I had access to a full machine shop, metal shop, an array of welding bays, shot blasters, sand blasters and pretty much anything else you could need, along with people that had been doing it all a long time that were always willing to help out. I got a lot from college but I got more for the guys I worked with. I really miss those days. My old man still works in a school running the workshop, kids aren't allow to do anything remotely dangerous these day, but he does have one lathe left, pillar drills and the like and a small mill. I can only gain access to them during the school holidays though  |

| |

Its not broken, its resting!

Max signature image height: 80px

|

|

|

|

|

|

|

Like you, I taught myself MIG welding, and to a lesser extent TIG. I'd never used a lathe before I bought one. And I did that because I was fed up with pestering friends for all the spacers, bushes, modifications etc that fiddling about with cars requires. About an hour after plonking the machine on the bench, I had a couple of locating pegs for fitting a stock Capri axle onto 2.8i springs. I also bought a small benchtop milling machine, and after ten years upgraded to a much bigger lathe, mainly to increase my productivity. Lathes and mills are fairly simple machines; it's the jobs you do on them that become complex and nobody is going to make a new scroll for a turbocharger in their shed first time they switch one on. Here are some simple parts:    That's some heater hose adapters to flush the matrix, some aircraft jacking pads and a jig for rebuilding diff mounts.  And a tool for removing the propellor from a Lycoming radial |

| |

|

|

|

|

|

|

|

Buy this and spend a great deal of time watching you tube videos and being EXTREMELY careful.  |

| |

|

|

|

|

|

|

|

|

^^^

You can make some basic small parts on things like that but do not expect great accuracy . And you can forget doing anything in stainless steel etc !

|

| |

|

|

|

|

|

|

|

|

The best advice I ever got about from machining was from my then boss. Not exactly what you expect to hear coming from a man who has just employed you. "I hope you know how to steal" 😳🤔

Elaborated upon by him saying ,"With your eyes and your ears". And it was really true. Ask loads of questions,as it's only stupid people who don't ask. Read loads. Watch loads. Try it out for yourself and then decide whether the advice given on the internet is Gospel truth or fake news. Don't get despondent when you cock things up. A good machinist isn't somebody that doesn't make mistakes. It's somebody who knows how to fix his mistakes,either by remachining or starting again. Best bit of advice,rule number one, don't stick your fingers,anywhere you wouldn't stick your willy. Rule number two, every machine you use has the potential to kill you. The louder you scream doesn't make it stop any faster. If in doubt,see rule number one.

There are loads of oldboys out there with a lathe or mill in the shed,who would be more than willing to show an interested person the ropes in return for somebody to talk to about a subject they hold dear. Win win scenario,as the oldboys are the ones with a wealth of knowledge that will go with them to their graves if we don't interact. 😊

|

| |

|

|

|

|

|

|

|

|

|

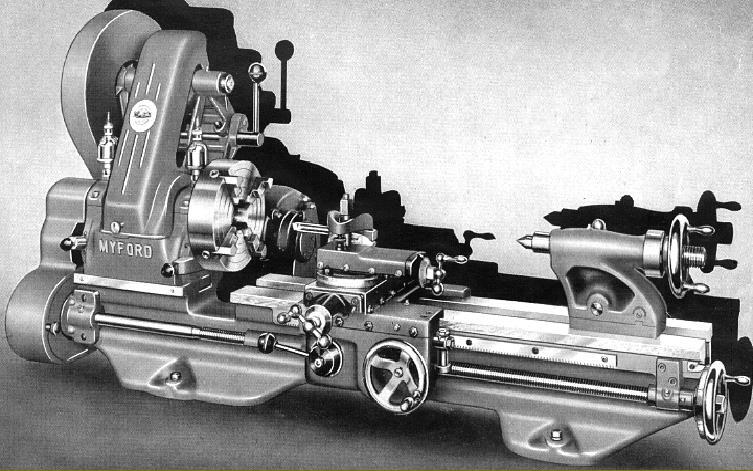

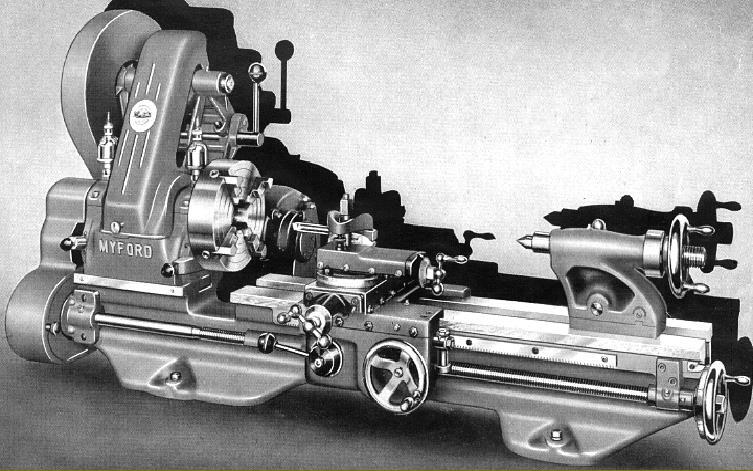

I did an evening class at are local college about 20 plus years ago. It was just a very basics on using a lathe, no qualification at the end of it. And it was only the start of this year that I finally got myself a lathe to play with. I have a Myford ml7 which is probably the best one that you could have for machining at home. Mine is 80 years old but still in perfect working condition. You can fit attachments to it so you can do milling as well. There’s plenty of them for sale on eBay and other places as well as all the parts to repair and upgrade them. You could get a brand new Chinese lathe for less than £500, but the quality and accuracy can vary a lot. YouTube is a great place to pick up information on how to use a lathe. And I have picked up some good tips from there. Where about’s are you, there maybe retro Rides members near you that can let you have a go on there equipment. It is a bit of a life saver having a lathe. I’ve lost count of the times it’s got me out of trouble when I couldn’t get a part or something has broken and I can just make it on the lathe.  |

| |

1955 Austin A30

1981 Jawa Mustang

1990 Trabant 601 (Tommy)

1989 Trabant 601

2009 Jaguar XF

2012 Toyota AYGO

2018 Scomadi TL

|

|

|

|

|

|

|

|

We have a Baleigh mini mill that was bought by my boss instead of looking for another bridgeport.

It really is rubbish - curse word paint and finish , sharp edges , its not accurate and it vibrates like hell . Worryingly the oil in the top has turned black within about 1 hr of use .

Its complete junk and we could have got something tried and tested secondhand which is full size but my supervisor likes to think he knows everything !

|

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,787

Club RR Member Number: 49

|

Learning how to machinejonomisfit

@jonomisfit

Club Retro Rides Member 49

|

|

|

|

tubulcan / doubleboost on youtube.

buy a lathe, try making something, balls it up, buy some books, try again, try making harder things, keep trying, keep ballsing it up, try some more.

develop patience, and don't rush.

Learn how to set the lathe up properly for run out and slide float. This makes a huge difference to how well you do.

|

| |

|

|

|

|

|

|

|

As mentioned the biggest problem you're going to have is access to a machine As you will know when learning how to weld you need to mess about and practice A modelling lathe isn't likely to make much that would be used in modified cars but they are cheap and don't take up much room So a good way to learn and a foot in the door as such I was lucky my dad was an engineer/tool maker from leaving school So I could pick up things from him over the years he also has a mill and lathe of useful size There's a lot to learn speeds/feeds/tooling/angles and all different depending on what your cutting If I didn't have access to a machine I would have to buy one its just to handy Look up "warco" there a quite good quality budget company for all machine types        Just some of the little bits and bobs I've made in the last year or so My advice is If you have the space and you can afford to Then buy yourself a reasonable size lathe and start breaking some cutting tips |

| |

1992 240 Volvo T8

1955 Cadillac

1994 BMW E34 M5 (now sold )

1999 BMW E36 sport touring x2

1967 Hillman imp Californian "rally spec"

1971 VW bay window (work in progress)

1999 Mazda 323F

1987 Jaguar XJ12

All current

|

|

steveg

Posted a lot

Posts: 1,586

|

|

|

|

|

I've got a Warco lathe which is pretty much the same as the Clarke one pictured, they all come from China and a small milling machine. They are pretty good, if you can get a good used one as you often get extra chucks, tools etc.

My first useful lesson was to make sure I never left a chuck key in the lathe chuck and then turn it on. This was back at school when they actually allowed children to use things that were sharp !

From there I did a 4 year apprenticeship and learnt the basics, but with ever changing technology you don't ever stop learning.

I've had various jobs and while working at a paintball gun manufacturers was surprised by the boss there who taught himself to operate a CNC milling machine. He must have spent hours reading stuff and trying things out at the weekend but it proves you can teach yourself.

You will need at least a reasonable quality vernier caliper, possibly a bench grinder if you want to sharpen cutting tools along with a lathe. Don't forget some good safety glasses or even goggles. As apprentices we were shown some some suitably worrying videos showing how easy it was to scalp yourself or get tangled in rotating machinery when hair of clothes get caught up !

|

| |

|

|

merryck

Club Retro Rides Member

Posts: 480

Club RR Member Number: 9

|

Learning how to machinemerryck

@merryck

Club Retro Rides Member 9

|

|

|

Also many heritage railways now have useful machine shops and I'm sure would help you to learn in exchange for some unskilled work from you. My step dad runs a miniature railway. I know they have a very well furnished engineering shed and I can't work out why I didn't think of that!! I'll have an ask about doing some volunteering there. Some of you may recall I rebuilt their little railway bike a year or so ago. (https://imgur.com/FUbA3RK) Maybe I'll get them to show me how to run some wheels and I can make a bike to match the one they've already got. Thanks for all the advice! |

| |

|

|

|

|

|

|

|

|

Please let us know how you are getting on in a few months time! As many others have said - you will always be learning - but it is really satisfying knowing that.... "you made that!!"

|

| |

|

|