|

|

|

Oct 19, 2019 17:11:59 GMT

|

|

Evening

Quick question might be a stupid one.

Usually when I do work on my car I have to run a 50m extension cord to my garage the kind that's on a reel. Its been fine for all my grinding.

Is this likely to cause me any issues if I use the extension cord for welding?

Cheers

|

| |

1967 Beetle

|

|

|

|

avg

Part of things

Posts: 168

|

|

Oct 19, 2019 17:34:14 GMT

|

|

Yes it wont work anywhere nears as well as plugging into a socket. You really need heavy duty cable. I have tired and it was a curse word result. don't ask me tec details as I don't do electrics lol

|

| |

|

|

|

|

|

Oct 19, 2019 17:51:49 GMT

|

|

I run mine down an extension lead, I suspect it would work better if I could put it directly into the socket but that's at the front of the shed, around 60' from where I am welding. I would think 50m will make more difference unless it's particularly thick cable, but then it probably wouldn't roll up very well.

I believe you should unwind the whole thing if you're going to put welding current through it.

|

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

Extension Cables/Weldingsowen

@sowen

Club Retro Rides Member 24

|

Oct 19, 2019 20:09:57 GMT

|

|

Unwind it all the way as it'll get very hot where it's still coiled together.

|

| |

|

|

|

|

|

Oct 19, 2019 20:20:23 GMT

|

|

As mentioned it needs to unwound so it doesn't become a electric bar heater

And you will loose ampage across its length so you may need to increase the ampage on the welder to make up for the loss

It's not ideal but I can work

|

| |

1992 240 Volvo T8

1955 Cadillac

1994 BMW E34 M5 (now sold )

1999 BMW E36 sport touring x2

1967 Hillman imp Californian "rally spec"

1971 VW bay window (work in progress)

1999 Mazda 323F

1987 Jaguar XJ12

All current

|

|

|

|

|

Oct 19, 2019 20:40:28 GMT

|

|

Thicker cable will help. If you can find a drum of say 2.5mm flexible cable, and terminate each end with a 16A ‘commando’ plug/socket (and make up adapters to 13A plugs) it will work much better than a long domestic type extension.

I do this when I need to use my MIG outside, works fine.

If you’re anywhere near Luton I have a new unused drum that I’d be willing to sell cheap!

|

| |

|

|

|

|

|

Oct 20, 2019 16:39:34 GMT

|

|

Cheers! Will I need to change the plug on the end of the welder as it's the 3 pin 13a one.

|

| |

1967 Beetle

|

|

|

|

|

Oct 20, 2019 19:34:57 GMT

|

|

Not necessarily. If it’s intended to run off a 13A supply and expects to have a fused plug, I’d leave that as it is. Check the max current required on the data plate.

You could then have a short cable that goes 13>16 at the feed end and 16>13 at welder end with appropriate male/female plugs & sockets.

OTOH if the welder spec wants more than 13A, it should have a 16A* connector, and consider fitting a 16A socket at the house/garage especially for it.

* Depends what the welder’s max current is. My 230A MIG has a max input current of something like 26A @ 230v, so it’s fitted with a 32A plug and I have a suitable 32A socket in the garage for it.

If I’m using it for car repair work it’s only running at about 1/2 power so fine on a 16A supply, and will work on 13A in short bursts.

|

| |

|

|

|

|

|

Oct 21, 2019 12:20:41 GMT

|

|

If that's 50 metres of 1.5mm cable as a typical household extension will be then it's no good.

Make one up from 2.5 that's as short as you reasonably can and you should manage ok, but if welding at high current there may still be noticeable voltage drop which will require you to increase the voltage / current of the machine and you may end up blowing fuses.

From experience.

A sensible length cable made from 2.5 and not coiled will be fine for automotive welding.

|

| |

|

|

|

|

|

Oct 21, 2019 12:26:12 GMT

|

|

From experience you can get away with 13a plug and fuse up to 150a without problems.

However if you leave the cable coiled you will destroy it, as experienced helping a friend once years ago.

|

| |

|

|

|

|

|

|

|

Oct 21, 2019 14:16:22 GMT

|

|

roughly 50mtrs of 1.5 3 core flex will give you about a 16 volts drop when pulling 10 amps, 50mtrs of 2.5 3 core flex will give about 10 volts drop when pulling 10 amp, but once the voltage starts to drop you pull more amps which makes matters worse! so go for the biggest cable and shortest length you can

Also your supply voltage can vary a lot depending on how far your electric comes to start with!

|

| |

|

|

|

|

|

|

|

|

50m is the shortest length I can get away with.

Other than practice is there a way I can work out roughly how much voltage is being dropped so I can dial my welder in to make up for the drop?

|

| |

1967 Beetle

|

|

slater

Club Retro Rides Member

Posts: 6,390

Club RR Member Number: 78

|

Extension Cables/Weldingslater

@slater

Club Retro Rides Member 78

|

|

|

|

Over 50m of 2.5mm you will drop about 4.5v at 13amp

(0.35ohm resistance in the cable)

Not really much to worry about! If you draw less current the drop will be less.

|

| |

|

|

|

|

|

|

|

Over 50m of 2.5mm you will drop about 4.5v at 13amp (0.35ohm resistance in the cable) Not really much to worry about! If you draw less current the drop will be less. Excellent info. I can add though that during welding you will be at way over 13 amps. I know this sounds wrong as its a 13A supply and plug and fuse etc etc but I had reason to measure it years ago, I don't have the info any more but I seem to recall that with the 210A machine I was using at the time from a 13A supply was using around 30A I had a problem with my welding machines, and lathe and milling machine via a single to three phase converter dimming next doors lights and needed to do some investigation to let the electric board know I was doing and ask them to improve my supply. Slater, can you estimate the drop at 30A as an example please? |

| |

|

|

|

|

|

|

|

|

Just to add that at top whack the welder mentioned above blew the fuse occassionally, but the reality is that you need a lot more than 13A to blow a 13A fuse quickly, it needs to allow 13A to be used continuously so can take well over for a time.

|

| |

|

|

slater

Club Retro Rides Member

Posts: 6,390

Club RR Member Number: 78

|

Extension Cables/Weldingslater

@slater

Club Retro Rides Member 78

|

|

|

|

For 30 amp it would be 10v on 2.5mm 4v on 4mm and 1.8v on 6mm cable. 4mm would be the minimum safe cable for that kind of amps even over a short run tho.

|

| |

|

|

|

|

|

|

|

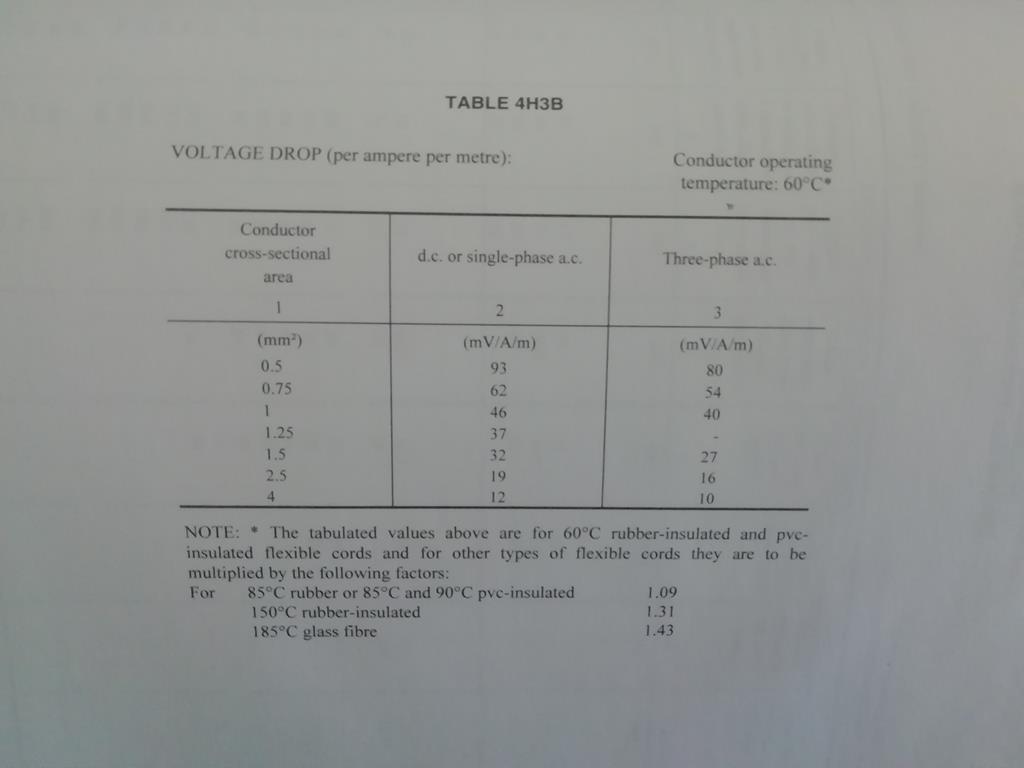

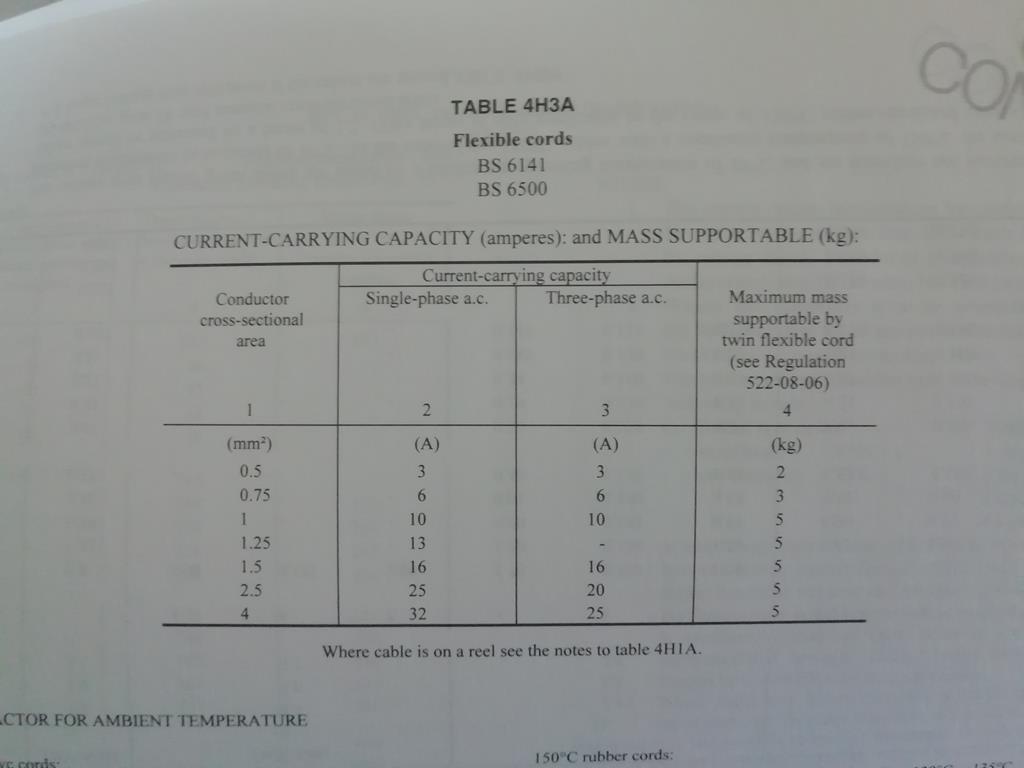

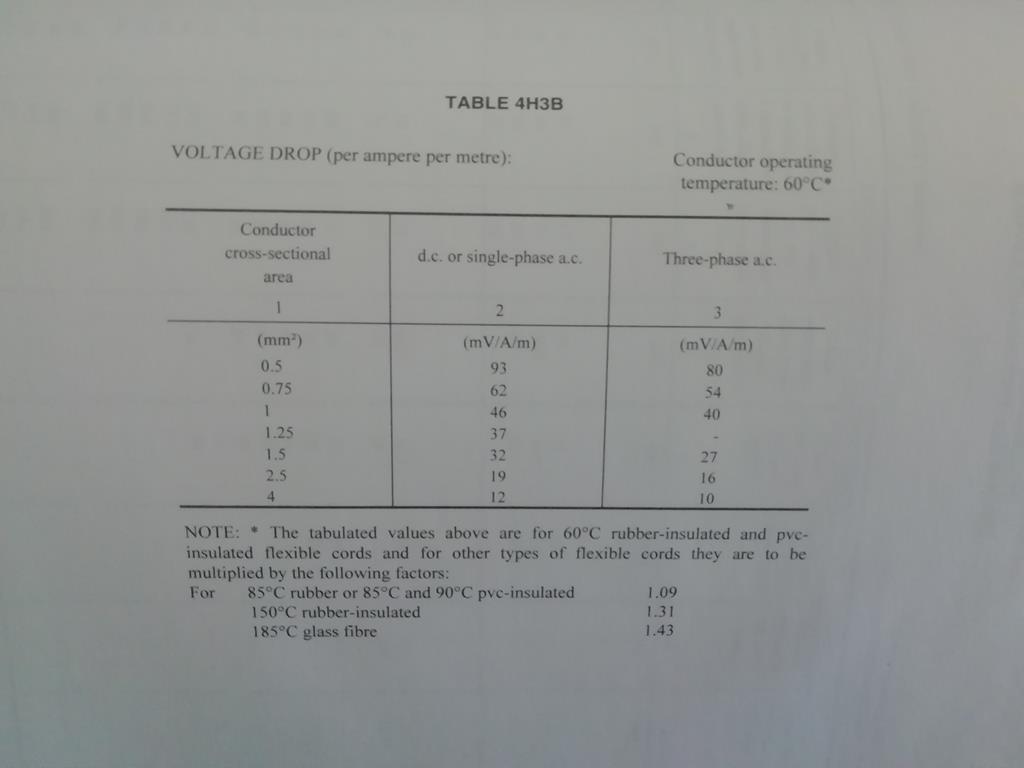

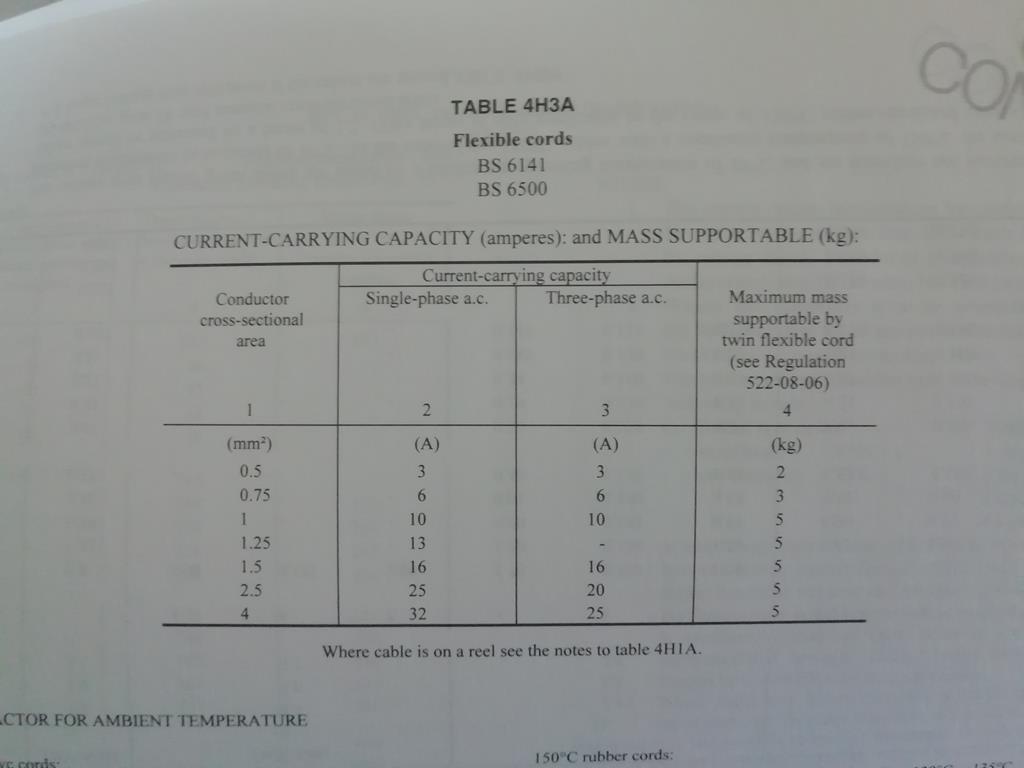

I'm not sure where the figures above are coming from as they are not correct, see the pictures which are industry standard and used by the cable manufacturers and electricians   So 50mtrs of 2.5mm 3 core will give about 10volts drop at 10amp, 13amp 3 pin plugs are not rated at 13amp for long periods just intermittent use any thing longer needs to be a hard wired switch or spur |

| |

|

|

|

|

|

|

|

|

That's why you can get away with running a welder from a 13a plug, you spend very little time actually arced up and they use very little at all in between.

Not saying its correct or ok, just you can get away with it, at your own risk. I have done very many times.

My current portamig doesn't have a 13a plug though.

|

| |

|

|

|

|

|

|

|

|

I have also learned that while you can use way more than 13a for short time 13a for a long time is not ok (as you said).

I connected a 3kw heater to a 13a plug and eventually cooked the plug and socket.

|

| |

|

|

slater

Club Retro Rides Member

Posts: 6,390

Club RR Member Number: 78

|

Extension Cables/Weldingslater

@slater

Club Retro Rides Member 78

|

|

|

|

I calculated assuming a resistivity of 1.7x10^8 which I nicked off the internet for copper at 20c. The table assumes 60c which is what probaly creates the majority of the descrepincy.

|

| |

|

|

|

|