|

|

|

Apr 24, 2020 15:53:23 GMT

|

|

the 200 runs great! i guess you have a few hundreds miles of running in to do before you can judge it?

p.s not to sound stalky but i recognised a few landmarks in the video. it reminded me of a video from last year of v8jim driving round in his 200tdi model T (which at the time i remember watching and remarking to myself how non-stalking it was by recognising things) but anyway, digress, it appears that you are quite close to each other. not a million miles from me, but too far for my hobby sized teles.. i mean too far for A hobby sized telescope to see. i'd have be sat outside, which i'm not obviously, and if i were i would only need my binoc... i mean i would only need SOME binoculars anyway. hangon, someones honking ive got to move the car....erm, i meant the kettles whistling downstairs.

|

| |

|

|

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

Apr 24, 2020 19:39:13 GMT

|

|

Jim lives very close to me. I cross his road on the way to work if I walk.

I did wave at you the other day when you were sat outside with your camera, but you pretended not to notice.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Apr 24, 2020 22:25:53 GMT

|

|

I seem to be a bit late to this party. Only just arrived and it seems to be nearly done.

Cracking job though!

James

|

| |

|

|

|

|

|

Apr 24, 2020 22:37:24 GMT

|

I seem to be a bit late to this party. Don't worry, James, I think we're just getting to the interesting stuff now. The rest was only about vehicle repairs.  |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

Apr 24, 2020 23:51:41 GMT

|

I seem to be a bit late to this party. Only just arrived and it seems to be nearly done. Cracking job though! James I don’t think you’re late in the grand scheme of things. True, the work I set out to document at the start of this thread a fortnight or so ago is nearly done, but there’s still enough to do that I’m sure this thread has the potential to trundle on for a couple more decades.  No physical progress to report today, as I had to go to work. I did a few brief trips around the block this morning to see if I could shake anything loose, and all seemed well, so I drove to work in it this afternoon. General impressions are very favourable. The new clutch setup is dramatically lighter than the old, which is every bit the end result I was hoping for. The new rear prop, engine mounts, tie bar and clutch etc have totally eliminated the clutch judder that’s plagued me for years, which is another massive bonus. These two factors alone have transformed how the vehicle feels to drive and would almost have been worth all the work just on their own. The ability to use third gear again is great, and contributes to a much less frantic drive too, although I need to unlearn the habit of looking for overdrive in second...  The brakes, too, need a much lighter right foot than before. Granted, they’re not (and never could be) as light and progressive as a modern vehicle, but the new setup gives much more feel than the old, and the dual cylinder offers an inbuilt bias towards the front that the single circuit system couldn’t. A couple of carefully executed emergency stops showed that the old tendency to lock the rear wheels under heavy braking has been replaced with the ability to lock the fronts instead; and with way more control. Finally, the engine feels tight, smooth and brisk. I shall fill up with diesel tomorrow, and am looking forward to seeing what effect the renewal of the bulk of the mechanicals has on economy. I’m also looking forward to getting the floor and mats back in, before I go deaf! :lol: I had some bits arrive to let me get a bit further down the road with the heater and split charge install, so hopefully I’ll get more of that done over the weekend. I’m still waiting for a few bits though, so it might be into next week before they’re all here and I can get done. I’ve a lot of tidying and sorting to do now though, that’s for sure.  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

eternaloptimist

Posted a lot

Too many projects, not enough time or space...

Too many projects, not enough time or space...

Posts: 2,578

|

|

|

|

|

Absolutely love what you’re doing with this. Hats off to you.

|

| |

XC70, VW split screen crew cab, Standard Ten

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

|

|

Had a couple of bits arrive in the post today. One of which was the screenwash bag. Quite a comprehensive kit for £9 posted. Everything you would need to fit it from scratch. Granted the switch and wiring are a little shonky, but they’d work.  I only used the bag and its hanging bracket though, and tucked it up under the passenger wing. It’s not a permanent solution in my mind, but it’s certainly a cost effective temporary answer to the problem that I can review at a later date.  It all works fine. I don’t know how long a full bag will last, and it’s a bit awkward to access for topping up, but overall I’m pleased. Next job was to refit, permanently, the diesel heater. So that’s now in place, and the ducting secured. I have been going around in circles with regard to my battery situation. I currently have a couple of pretty old ones fitted, the main being a 2008 dated one, and the second a 2006 that came secondhand when a friend needed it replaced. They’re mismatched size wise, and would likely need changing anyway before too long. I don’t really want to faff about making a new securing clamp that’ll then need revising shortly, nor do I want to lay out the wiring for the split charge setup, only to find I have to redo a load of that too if battery sizes/terminal layouts change... So, on the basis that I didn’t spend out on a new exhaust last week, I spent out on a new Optima Red Top battery today instead. If my funds remain ok through the month then I’ll get the matching yellow one next payday. After that I turned my attention to the wiring loom for the diesel heater. Earlier on in the thread I highlighted the fact that it was a generic layout, with some kind of adhesive tape wrapping. First job was to record which colour wires went to which pins on the plugs for the fuel pump and controller, so that they could be de-pinned, getting the big plastic plug shells off the ends of the cables. Then the job of getting the tape off started. Dear lord, what horrible stuff. It was stuck so well it wouldn’t unwrap, and needed cutting off, leaving a sticky adhesive residue behind. It took me ages, first to get the tape off, then to get rid of the sticky. If I’d known how long and how grim it was going to be to do I’d have laid in a stock of new plug and socket pins, and simply started again from scratch. Still, once it was done, I shortened the fuel pump line to a sensible length, and carefully re-wrapped it all up in heatshrink. Heatshrink is one of my favourite wiring accessories; it really does a good job of protecting the cables, as well as visually making things neat and tidy.  I shall start fitting it tomorrow. On a final note, I knew that I’d be having to fit some cable terminals to some fairly hefty charging cables as part of this job, and while I have crimping pliers for small ones, and a pair of huge dimple crimps for large ones, I had nothing in between. I took a punt on a pair of £18 ones from eBay and I have to say that I’m pleased with them too. They make a nice tidy crimp.  So, that’s your lot for tonight. More tomorrow.  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

Phil H

Posted a lot

Posts: 1,448

Club RR Member Number: 133

|

|

|

|

|

I’ve just bought the same crimping tool - it looks to be half decent for the money although I haven’t actually used it yet (found another way to do the job easier in the end).

|

| |

|

|

|

|

|

|

|

|

There was a thread on lrukforum about screenwash bottles (life in the fastlane) the unipart ones fitted as oem to series 3 are now comically rare, changing hands in secret for undisclosed sums like they are faberge eggs or something

But as they used an external inline lucas pump, the options for vessels are limitless

|

| |

|

|

|

|

|

|

|

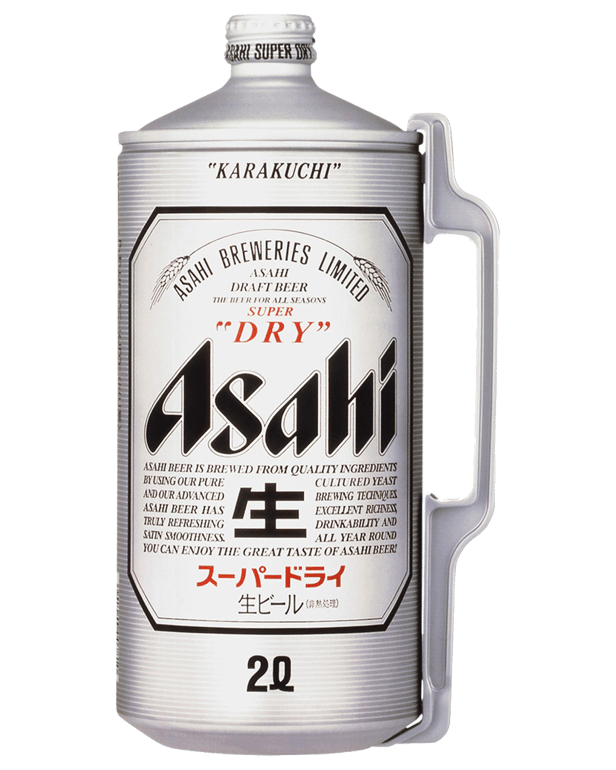

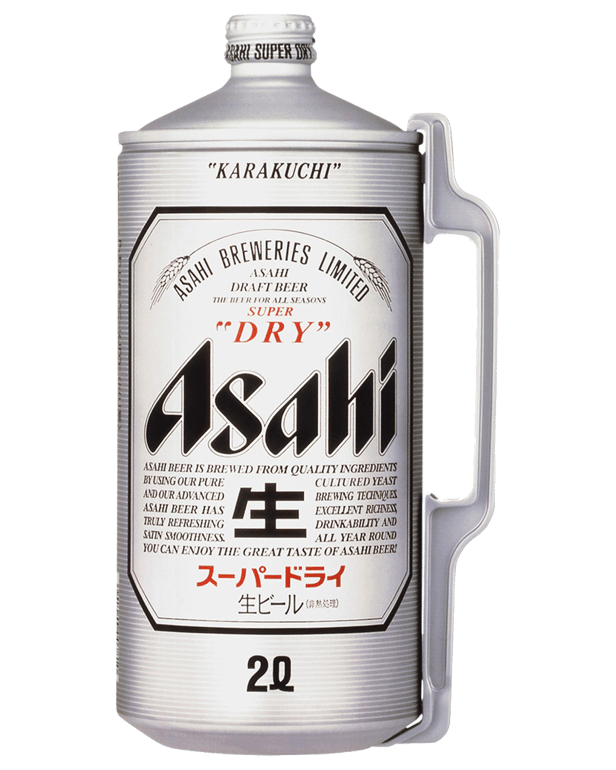

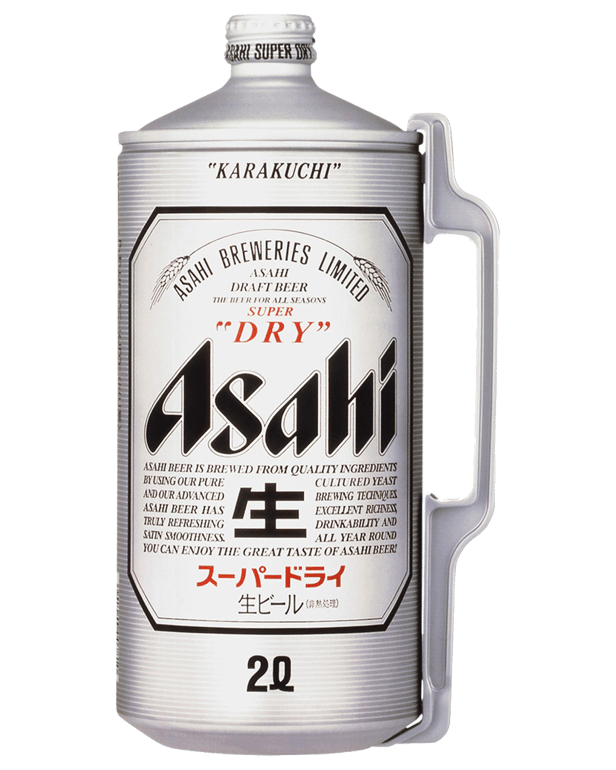

When mine eventually falls apart (it's getting close!) I'm going to replace it with a 2l asahi can. For origin reasons.  |

| |

|

|

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

Apr 26, 2020 10:18:34 GMT

|

When mine eventually falls apart (it's getting close!) I'm going to replace it with a 2l asahi can. For origin reasons.  Nice. I like your style. 👍😃 |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

jamesd1972

Club Retro Rides Member

Posts: 2,920  Club RR Member Number: 40

Club RR Member Number: 40

|

|

Apr 26, 2020 12:37:28 GMT

|

There was a thread on lrukforum about screenwash bottles (life in the fastlane) the unipart ones fitted as oem to series 3 are now comically rare, changing hands in secret for undisclosed sums like they are faberge eggs or something But as they used an external inline lucas pump, the options for vessels are limitless Ooh ours might have to go on fleabay ! Don’t think it’s going to fit with new air cleaner location . James |

| |

|

|

|

|

|

|

|

If you're going for the local washer bottle look, then one of these?   |

| |

|

|

|

|

|

|

|

|

I wonder if the washer bag (just like the original fitment in my former 74 Alfa, BTW) will last with all the heat that the turbo will kick-off? John

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

|

|

|

Time will tell. It won’t freeze in the winter. 🤣

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Apr 27, 2020 15:58:49 GMT

|

|

It will be fine - its got a nice water heat sink in it.

Remember the school experiment with a bunsen burner under a cardboard container full of water? cardboard won't burn while water is in it.

|

| |

|

|

|

|

|

Apr 27, 2020 19:19:54 GMT

|

It will be fine - its got a nice water heat sink in it. Remember the school experiment with a bunsen burner under a cardboard container full of water? cardboard won't burn while water is in it. Great point! John |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

Apr 27, 2020 22:49:22 GMT

|

Hi everyone. Sorry no update yesterday. Not that there was no progress, but I was shattered at the end of the day and simply didn’t think I could stay awake to do it. So you lucky lot get a double helping today.  First job, yesterday, was to refit the diesel heater permanently, along with its ducting to the outlet in the cabin. I had the proper edge trim arrive, and you can just about make it out where the duct pipe passes through the side of the toolbox. It was quite tough to get on, but it does a smashing job. Very pleased how such a cheap and simple thing both protects the ducting, and neatens the job up.  With that in place, the next job was to start laying in the wiring loom. No real pictures of this as it’s deliberately tucked out of the way. I have a bit of a reluctance to drill holes anywhere in the Land-Rover that I can possibly avoid, and I’m pleased to report that I got it all clipped in without adding any more perforations. One leg of the loom goes to the battery box, the other toward the rear, and then splits behind the toolbox, one part to the fuel pump, the other to the control box. I’m putting the controller just inside the driver’s door, on the B-pillar. That way I can turn it on or off without getting in, or from the front seat if I’m driving, I can also reach it if I’m sat in the back, and it’s not vulnerable to damage from moving loads or clambering feet. A later upgrade to a controller with a remote activation function is a possibility, but at the moment I’m not bothered. I fitted the diesel pump to the chassis crossmember just behind the toolbox, and will be connecting it via a filter to the length of fuel hose I T’d off the return to the tank earlier on in the saga. I’m still waiting for the hose tails to fit the filter head though, before I can progress that. With all the work in that toolbox completed for now, it was time to put the lid back on it. Because the space it occupies is normally a fuel tank, the lid screws down. I’m not worried about having instant access to the heater, or anything else that’s likely to get mounted in there with it, so I saw no sense in modifying the lid for easier entry, but if it does turn out to be necessary, then I have a suitable spare locker lid from the other side I could press into use. What I did need to do though, was fit an inlet vent, so the heater could breathe properly; because for it to be able to blow out any hot air, then it needs to have free access to cold air to suck in. The DAF came to the rescue again with an inlet grille and backing ring, so a bit of measuring, drilling and filing later...   And then cut the sound deadening mat to match, and lay it back over the top.  The sound deadening mat already being cut to suit the screw down plate is one of the main reasons I chose to leave it. To fit a lid like I have under the passenger seat would mean further chopping about of this mat, and I really don’t want to be doing that if I don’t have to. The fuel pump looks like this, and is a simple impulse pump that delivers a metered dose of fuel each time it’s triggered by the controller.  And it connects with a standard “junior power timer” connector, which you can cheaply and easily source new pins for, so it was a doddle to trim the feed cable to a sensible length, crimp new pins on and refit the plug shell to them.  The last leg of the loom goes to the controller, so needed to come up back into the cabin. I brought it in, through a grommet, right in the corner behind the seatbelt bracket where it’s not going to get caught up by anything. One thing that I’m going to have to do though, before I cut this one down to length, is to put a plug and socket joint underneath the floor behind the toolbox, because otherwise the cable physically joins the seat box and rear tub together and would need the controller plug de-pinning to thread the cable back out to remove the seat box, which would be a PITA. I’ve a suitable plug and socket coming from China, and will fit that once it’s here. No picture of this as I forgot. :  With that done, I connected up the combustion air inlet pipe underneath, and ran it up towards the centre of the vehicle, above the right hand chassis rail behind the handbrake. Next was the exhaust, which is a flimsy bit of thin stainless flexi tube. Surprisingly, with a couple of support clips to the sill, and a clamp around the exhaust outlet, it all firmed up nicely. I have to make a bracket to support the silencer, but that was the end of Sunday’s efforts. |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

Apr 27, 2020 23:31:29 GMT

|

Right then. Today. Part one.  First thing was to rectify a mistake I’d made a few years ago... Land-Rovers of this vintage never had seat belts as standard. Not even unused mounts that you could specify belts as an extra, even the mounts were a cost option. Actually, pretty much everything was a cost option; heater, passenger side wiper, indicators, roof...  Over the years of my ownership, I have added them, copying the factory layout for a mid sixties vehicle first off, which suited the static belts I favour. When my lad came along, the statics were still ok because his child seat simply got ratchet strapped it being as it had its own harness. As he got bigger though the need for an inertia reel setup became apparent.  He’s grown a bit.  This coincided with me getting hold of a Series 3 rear body tub, which has a rear mounted fuel tank and filler, which liberates a bit of space behind the driver’s seat that’s normally occupied by a filler tube. This in turn allowed me to fit the mounts necessary for a mid 80s onward setup, which tucks the reel in neatly in a bit of otherwise unused space. I salvaged the mounts from a scrap 110 tub that a mate was breaking. As is often the case, they got fitted in a bit of a rush, and when it came to mounting the belts I unthinkingly spun some 5/16” UNF nylocs down the mounting studs, forgetting that they’d actually be M8. Doh. Needless to say, this kippered the threads. I got around this by just ignoring it and hoping for the best, but I had to undo them to get the seat box out at the start of this little marathon, and there was no way I could knowingly put them back. So, off came the brackets today.  With their damaged threads.  It was a simple job to grind back the heads of the captive bolts and weld in suitable replacements. These ones are definitely 5/16”.  These are in a pretty good place for some heavy electrolytic corrosion if you’re not careful, so a coat of etch, a coat of stonechip and a liberal application of underbody seal to the area and the back of the bracket before refitting them, and another good squirt all around after they went back in.  This is where the studs poke up inside the cabin, behind the seats. That wire in the corner feeds my interior lights and radio at the moment, but the heater controller cable I mentioned earlier comes up in the same place on the driver’s side.  They allow you to use these brackets, and reels.  Which fit right up in here like this.  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

glenanderson

Club Retro Rides Member

Posts: 4,340

Club RR Member Number: 64

|

|

Apr 27, 2020 23:58:22 GMT

|

I wasn’t just standing around waiting for paint to dry though, whilst the above was all going on I got a delivery.  This was the replacement gearbox tunnel I’d ordered early last week finally turning up. I suppose we should be grateful we’re getting deliveries at all, but I could really have done with it before the weekend. Hey ho.  It wasn’t exactly in the “good condition” as described, not in my book anyway, with a few dents not apparent in the photos, a couple of small splits at the mounting holes some corrosion damage and a load of caked on grime. Still, beggars can’t be choosers and it’s not as butchered as mine. It’ll do for the foreseeable. I’ll keep my eyes open for a better one to put into stock for the next time it’s apart. I gave it a good clean and then very carefully marked out and cut a hole for the overdrive lever to go through.  With that done, I gave it a bit of a keying up with some wet and dry, then etch primed and stone chipped the underside.  The factory didn’t consider painting the undersides of these necessary, but I figure it can’t hurt, and given the corrosion on this panel, it should stop it getting any worse. I will maybe stick some flashband under it tomorrow too. We’ll see. The top then got a similar etch prime and some colour. I used a much more restrained grey colour than the bright green on the floors. Really I should have done the floors grey too, but it’s too late now. They’re all covered by the floormat anyway.  With luck, I can get the floors back in tomorrow, although I’m likely to leave the tunnel mat off for a few days to let the paint properly cure. I don’t want the mat sticking to the new paint. So, that brings us up to date. My new battery is due tomorrow, and I’m hoping to get that installed too, but it depends what time it arrives. There’s a few more wiring bits coming too, because I’ve been firming up my plans for the future revisions, and I want to have the foundation work done properly for them and not be having to revisit any of the split charging setup. Nearly done for the current works though, and very pleased so far with my efforts.  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|