|

|

|

Jan 29, 2021 15:56:54 GMT

|

I've had my integrale since 1997. It's midly modified to give 300bhp with a hybrid turbo, manifold and exhaust, intercooler mod, coilovers, 996 monoblock calipers and diff cradle with lower strut brace. Importantly though it looks standard.

I'm the second owner, first in UK,

About 20 years ago I bought a second which was going to be a mid-life crisis project but houses and kids came along and I just never got round to it. It had been partially stripped with the intention to turn it into a trackday car but the then owner decided he could go faster for less money in something else. When it came off the road it had done 34k miles. With the house finished and the kids self-sufficient I've enventually started the build, the plan is to optimise the car but retain the standard look. I'll begin with stitch welding the chassis as the original 1970's design was never meant for the stresses the car now generates.

I completed the strip down a few years ago so over winter knocked up a couple of frames that attach to the front suspension pick up points and the rear diff mounts. I'll be building a spit at some point so I can get to the underside eaasier.

The (first and) last car I rebuilt was a Triumph Spitfire in the late 1980's so I'll welcome all feedback on what I'm doing, workmanship and product suggestions.

I'll apologise that progress will be slow, it's taken me almost 20 years to get this far.....

|

| |

|

|

|

|

|

|

|

Jan 29, 2021 16:20:29 GMT

|

|

Love these, always wanted one but never had the opportunity.

|

| |

|

|

maf260

Part of things

Posts: 534

|

|

Jan 29, 2021 16:39:23 GMT

|

|

Oh. My. Word.

I'm in for the ride, following with interest.

I bet you can't believe your luck with the values of these now!

|

| |

|

|

|

|

|

Jan 29, 2021 17:21:01 GMT

|

Oh. My. Word. I'm in for the ride, following with interest. I bet you can't believe your luck with the values of these now! Thanks. The values have gone crazy in recent years. The newest is now over 25 so the US is taking a lot of cars pushing prices up even more.

Luckily I bought both when prices were sensible.

|

| |

|

|

|

|

|

Jan 29, 2021 17:29:41 GMT

|

|

I probably should have added that it's a 1992 evo 1. The last of the homologated models so that means big turbo and no cat.

The later evo 2 had a touch more power made with a smaller turbo and a cat but better ecu. I like the 1 as it's the real deal in my mind. Being build for Group A there are loads of nice touches like how the complete front of the car is an air intake, it has a cooler for the power steering fluid and the front suspension towers were higher than the previous version for increased travel.

|

| |

|

|

|

|

|

Jan 29, 2021 21:43:59 GMT

|

|

Wow... will be following this with great interest as the Integrale was very much one of my childhood heroes! Not usually a fan of big arches etc, but I've always really liked these from back when they were new. Guess it's because the additions all look like they were there for a reason as opposed to being just styling.

Truly awesome and iconic cars.

|

| |

|

|

bricol

Part of things

Posts: 290

|

|

Jan 29, 2021 23:06:57 GMT

|

Its easier to use the front and rear bumper mounts as points to attach it to a spit - although I can't imagine it needs much with only 34,000 on the clock? Having it upside down does make fitting things to the underside easier though. Stitch welding won't necessarily help much - but it will put more stress into the areas that are known weak points - top and bottoms of the A-pillar, center tunnel where the inner mounts for the front seats and the handbrake are, and the "chassis legs" in the engine bay. I found anywhere where three layers or metal (outer sill, inner sill, edge of floor for example) joined two, it cracked. It needs bracing - reinforcing plates - I made mine, but you can buy them from several specialists. Just for a laugh, if you've not done it, with your road car, with the wheels on the ground, put you hand over the area where the rear corner of the bonnet sits into the corner between the top of the front wing and the scuttle - then move the steering wheel side to side . . .everything moves in all directions, even on good ones. If you've not found it yet, evocorner forum has a lot of info in the FAQ on the front page - forums.delphiforums.com/evoforumI bought my 16V in around 2005, put 100,000 miles on it in all weathers, stored outside, commuted to work in Germany every two weeks for a while. Bought an evo1, sold the 16V a year later having fixed all the stress cracks, small rusty bits, oil leaks on the evo, and then put another 100,000 on the evo1 in ten years in all weathers again, including with a trailer on the back - which is when you find out how good your engine is, as you can be on boost for a long time if you aren't careful - mine was good:) Now owned it for 18yrs, its on close to 200,000, but for obvious reasons, its not gone far in the last year. I've turned down some good offers, but driving it puts a big smile on my face, even standing still it does. If you need an as new-head with new guides, new valves, mildly ported . . I have one sat in the front bedroom  I'm never going to fit it as my plans changed. |

| |

|

|

|

|

|

Jan 29, 2021 23:40:28 GMT

|

|

Oh hell yeah. Stone cold awesome cars. Watching!

|

| |

|

|

|

|

|

Jan 30, 2021 11:57:17 GMT

|

|

Thanks Bricol. I’ve been on evocorner since 2003, you probably know me as fiche2 on there.

The stitch welding of the cabin, especially across the floor pan has been recommended by some well-respected grale specialists. Not necessarily to reduce cracking but to give the shell more torsional strength. I’ll be making up reinforcement plates for the lower and upper A pillar sections, both outer chassis rails forward of the windscreen and the inside of the offside front bulkhead where the rail meets it. I’ll also be welding around the B pillars and round the rear strut turrets.

I’ll be using the bumper pickups for the spit, it’s simply mounted on dolleys at the moment hence the use of suspension and diff points.

|

| |

|

|

|

|

|

Jan 30, 2021 12:19:40 GMT

|

|

Yes, bring it on ...

|

| |

|

|

|

|

|

|

|

Jan 30, 2021 15:44:04 GMT

|

|

Awesome cars these would love one in yellow..

|

| |

|

|

|

|

|

Jan 30, 2021 18:11:20 GMT

|

|

Absolutely love these, had a chance to buy one from my mate many years ago for £3600, I’m honestly not kicking myself.

|

| |

|

|

e30ben

Part of things

Posts: 71

|

|

Jan 30, 2021 19:13:41 GMT

|

|

Fantastic read... intergrale was the only car I had been in that had such violent acceleration/ boost/ both that it hurt my belly muscles.... fond memories!

+ 1 regarding timeframe I bought my E30 318is in 2013 as it was dirt cheap.... 2021 and I’m only half way round... young family delayed it but never wanted to give up so locked it up, used to drink more than the weekly garage rent do swapped it round! .

|

| |

|

|

|

|

|

|

|

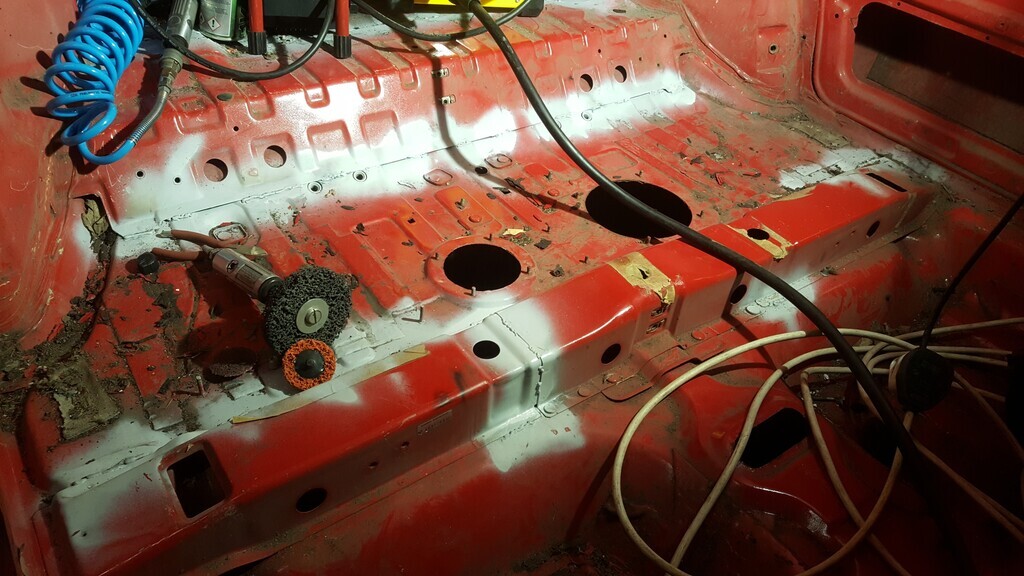

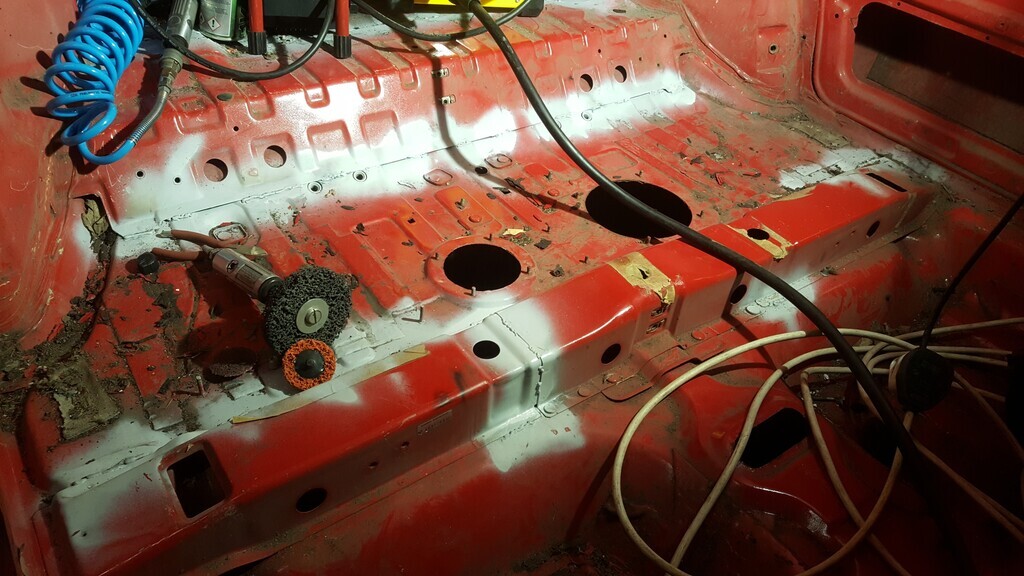

I knocked up the dollies from a few bit of frame work I had lying around, duly braced and with casters on they suffice ok. It means I can easily move the shell around to work on it then push it to the side when I'm done  A good poke around has revealed a reasonable amount of surface rust but no cracks yet. I'm sure they'll be there when I really start digging.  Don't look too closely in the welding as it was done on a cheap 30 year old mig - I bet the wire is 20yrs old.... Since bought a GYS Easymig 160 inverter which is proving to be fantastic. Over on mig-welding.co.uk the advice is never try to weld with an old machine so I bit the bullet and invested before I got into the project. I still need to do loads of practicing but with the new welder it's so much easier to get a half decent bead.  |

| |

|

|

|

|

|

|

|

|

Have to say, those are both stunning cars,

Always had a dream to own one when my mate had a UR Quattro but, with 2 rug rats and a mortgage, couldn't afford one even then,

(Now they've gone and I can afford one I can't afford one lol,)

Really looking forward to seeing future updates on this thread,

Nigel

|

| |

BMW E39 525i Sport

BMW E46 320d Sport Touring (now sold on.)

BMW E30 325 Touring (now sold on.)

BMW E30 320 Cabriolet (Project car - currently for sale.)

|

|

|

|

|

Feb 11, 2021 13:04:43 GMT

|

As I mentioned in my OP, the integrale shell is known to be quite weak and even a good looking car can suffer from stress cracks. While I've got the bare shell it seems like an opportunity too good to miss so I started welding the panel seams to add to the overall strength and regidity.   Some folks are recommending 30mm stitch welds from stacking up pulses and others claim spots are good enough. At the moment I'm practicing with both, my stitches are getting better but the spots look really neat and are showing good penetration on the reverse side with the underseal burning off. Moving forward to the rear strut towers and tying them into the inner wings and floor.   After stripping the seam sealer with a multi tool, I'm preparing the surface with a mixture of wire wheels and 3M/Norton surface prep products. I know cheaper ones are available but I'm finding the branded ones last longer so are worth the extra cost. After flap disking the welds if required, I'm dousing the stripped area with UPOL Zinc 182 for it's corrosion inhibiting properties.  After working in the garage this week I've been reading the garage heating thread with interest........ |

| |

|

|

|

|

|

Feb 11, 2021 16:19:14 GMT

|

What an utterly superb picture, very jealous of the car indeed! |

| |

|

|

shin2chin

Part of things

Making curse word cars slightly better

Making curse word cars slightly better

Posts: 820

|

|

Feb 11, 2021 17:12:07 GMT

|

|

Stunning car.

A mate years ago had one in black that we drove to a rave....that was memorable.

|

| |

1977 PORSCHE 2.0na 924

1974 VW Beetle 1600

|

|

|

|

|

Feb 11, 2021 18:40:45 GMT

|

|

Nice car and thorough work on the welding. I also seam welded most seams of my MGB before converting it to V8 to make the body more stiff.

I did not have the stress cracks. If you look at the theory, You should be carefull with welding stress cracks. Welding changes the material structure and it will be hardened and therefore less flexible and more prone to cracks. This is all theory. Things would improve if you could weld another plate in that area but doing this in the area as pictured is not easy. It may not be needed as the car might be pampered after the resto is done.

Keep up the good work as i like these cars and the work you are doing.

Peter

|

| |

|

|

|

|

|

Feb 11, 2021 19:35:29 GMT

|

Nice car and thorough work on the welding. I also seam welded most seams of my MGB before converting it to V8 to make the body more stiff. I did not have the stress cracks. If you look at the theory, You should be carefull with welding stress cracks. Welding changes the material structure and it will be hardened and therefore less flexible and more prone to cracks. This is all theory. Things would improve if you could weld another plate in that area but doing this in the area as pictured is not easy. It may not be needed as the car might be pampered after the resto is done. Keep up the good work as i like these cars and the work you are doing. Peter Thanks for the comments. I’ll be plating up the known weak areas, the seam welding or stitching is really to increase stiffness in general rather than in problem areas. The theory behind using spot welds is so they don’t allow cracks to propagate along them which is a distinct possibility with my welding. |

| |

|

|

|

|

I'm never going to fit it as my plans changed.

I'm never going to fit it as my plans changed.