Darkspeed

Club Retro Rides Member

Posts: 4,872

Club RR Member Number: 39

|

|

Jul 10, 2021 10:14:32 GMT

|

No probs  here you go here you goGoes from -0.5deg static to -0.7 under 3" bump, but it dips down to -1 between 1.5 and 2" (which is probably all the bump you'll see). What happens in bump is not hugely important as nipping along in a straight line does not usually throw you into a ditch - the key is what happens in roll and roll with squat in bend and powering out. And as expected the slightest bit of body roll and that loaded wheel goes positive and with squat and roll that loaded wheel goes over 7 degrees positive ! - which is why they wind on so much static. |

| |

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,872

Club RR Member Number: 39

|

|

Jul 10, 2021 14:46:51 GMT

|

And cut the slightly offset ones off   And after fabricating a new pair of bushes - weld them on  Assemble all the odds and ends from around the garage to make sure everything is present and correct  Now to get it boxed up and off back to krissto |

| |

|

|

|

|

|

Jul 19, 2021 11:29:40 GMT

|

Wishbones are looking good dude! What happens in bump is not hugely important as nipping along in a straight line does not usually throw you into a ditch - the key is what happens in roll and roll with squat in bend and powering out. And as expected the slightest bit of body roll and that loaded wheel goes positive and with squat and roll that loaded wheel goes over 7 degrees positive ! - which is why they wind on so much static. It'll be a little worse than that in actuality as well. Basically, the higher your roll centre the more cornering forces are fed directly into the wishbones rather than into the spring (it's actually to do with the slope of the n-lines that go through the tyre contact patches and the instant centres, but for a basic explanation the roll centre height suffices). I haven't quite got in my head where the forces fed into the wishbones actually go (do they just stress the component, causing heat and deflection, or do they push the car upwards). However, I do know that the effect basically reduces the amount of force the spring sees, which in practical terms means the suspension doesn't compress as much as you'd expect in a roll (unless your roll centre is sitting on the floor, and stays on the floor during the corner), meaning you don't get as much camber gain from suspension compression as you'd expect. You don't get as much roll either (as the spring sees less force, so the car doesn't roll as much), but the effect of a high roll centre is generally net-negative for grip. |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,872

Club RR Member Number: 39

|

|

Jul 19, 2021 14:49:49 GMT

|

|

The spring as the upper wishbone really complicates things because as Chris pointed out to me the spring does not act as a straight long lever with fixed inner pivot - it curves in a parabolic arc. The arc is determined by the progressive rate of the spring - the nice thing about leaf springs. So what you effectively have is an upper wishbone with an inner pivot that migrates inwards under load. But even at max bump it is still in essence shorter than it started but only if you have it de-cambered to be flat at static - If you fit a cambered spring and spring raising block the initial load will push positive.

Some fun would be had calculating that.

|

| |

|

|

|

|

|

Jul 19, 2021 15:17:37 GMT

|

The spring as the upper wishbone really complicates things because as Chris pointed out to me the spring does not act as a straight long lever with fixed inner pivot - it curves in a parabolic arc. The arc is determined by the progressive rate of the spring - the nice thing about leaf springs. So what you effectively have is an upper wishbone with an inner pivot that migrates inwards under load. But even at max bump it is still in essence shorter than it started but only if you have it de-cambered to be flat at static - If you fit a cambered spring and spring raising block the initial load will push positive. Some fun would be had calculating that. Now isn't that interesting... I seem to remember reading at some point about the way leaf springs compress and it being a bit counter-intuitive in that they deflect all as one unit rather than progressively, but I'll have to double check that. It would certainly be quite 'interesting' to calculate if they did move progressively, and I'm not sure what that would do to stuff like roll centre heights and whatnot. I do remember playing around with the real life model where I simulated a GT6 spring with layers of plastic oval tubing, cut to size and with cable ties where the shackles are. At full bump of the GT6 shocks the deflection is worth about 1.6mm in the total length of the upper arm. Not a great deal, but useful at any rate. I haven't got comparable data on how much camber that's worth. Need to try a hard link on the real-life model and see what that comes to. |

| |

|

|

|

|

|

Jul 19, 2021 16:08:04 GMT

|

|

I am loosely involved in modeling leaf springs at work, it's a very complex area with several methods available particularly when you include internal damping which means the stiffness becomes a function of the vertical velicity of the wheel as well as the static loads.

|

| |

|

|

|

|

|

Jul 19, 2021 19:30:26 GMT

|

I am loosely involved in modeling leaf springs at work, it's a very complex area with several methods available particularly when you include internal damping which means the stiffness becomes a function of the vertical velicity of the wheel as well as the static loads. Intriguing. Do you know if they deflect in a smooth arc or whether the longest leaf bends more than the others (and so on and so forth)? |

| |

|

|

|

|

|

Jul 29, 2021 20:26:11 GMT

|

biturbo228With respect to your model, may I ask how you arrived at 674mm between wishbone bracket eyes? From Triumph drawings or measurements form a genuine GT6/Vitesse chassis? I ask because something is not right with my own brackets, which were cloned a thousand years ago, from a scrap Vitesse. I fear that they are 1/4" out from standard and would explain the weird excess -ve camber I get when on the deck.

|

| |

|

|

|

|

|

|

|

biturbo228With respect to your model, may I ask how you arrived at 674mm between wishbone bracket eyes? From Triumph drawings or measurements form a genuine GT6/Vitesse chassis? I ask because something is not right with my own brackets, which were cloned a thousand years ago, from a scrap Vitesse. I fear that they are 1/4" out from standard and would explain the weird excess -ve camber I get when on the deck. Bother I think you're right! Way back when I made the first model, I used the chassis diagram on Canley Classics here. However, looking now they point out that the factory dimensions are wrong! From centreline to the roto bracket should be 315.7mm (so 631.4mm between eyes). Nearly a inch different on each side from my model! Will see about amending the model. Need to go and find out which are the dimensions that I've measured in real life, and which ones I've worked out from the model (I suspect it's kingpin angle that I've worked out, so might change). Does that new measurement fit with what you're measuring on your chassis? |

| |

|

|

|

|

|

|

|

Update: The Darkspeed wishbones are back from being painted in Poseidon metallic blue. They are great. ..    Next step is to accurately plot the eye-to-eye distances on graph paper and set the nominal length to be approx 7mm shorter than standard. Why? Because my chassis brackets that I made, so many years ago, appear to be 1/4" further out from the chassis vertical than OE Triumph. I need to post on the various Triumph forums to get the truth on the chassis inner mounting hole offset. The Canley repro items have an offset of just over 1" to hole centre, but my brackets are 1.25" - and I copied them faithfully from a pair of brackets cut from a Mk2 Vitesse. It is all very confusing. Maybe there is someone on the RR forum with a genuine GT6 and/or Vitesse chassis that might take some measurements for me? Thanks to all, Chris |

| |

Last Edit: Aug 6, 2021 19:58:09 GMT by krissto

|

|

|

|

|

|

|

|

|

|

I have a real GT6 Roto chassis and I reckon the back end of it is ok. What measurements do you need? They are awkward to measure iirc, lack of decent datum points. We made a jig to go on the diff and used that to transfer the dimensions to a non-roto chassis .

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

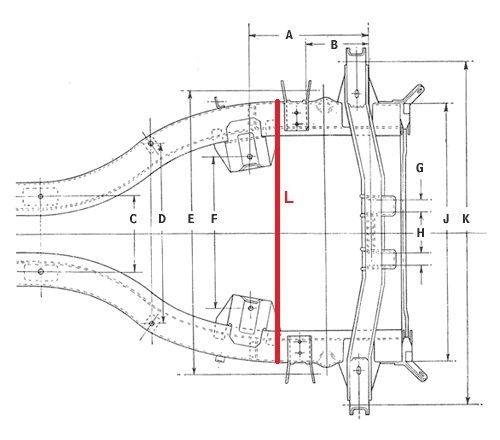

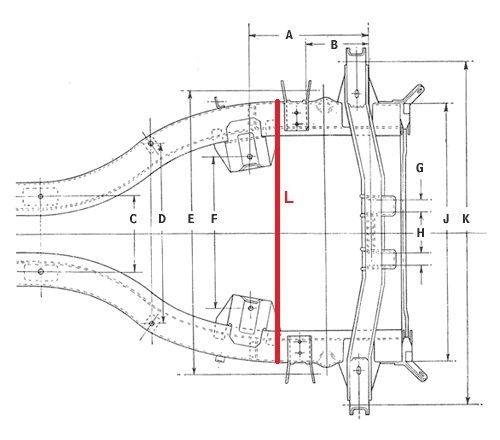

I have a real GT6 Roto chassis and I reckon the back end of it is ok. What measurements do you need? They are awkward to measure iirc, lack of decent datum points. We made a jig to go on the diff and used that to transfer the dimensions to a non-roto chassis . Nick Thanks Nick, Please would you measure dimensions E (should be 24.86") and L (i.e. the total width of the chassis just in front of the wishbone bracket) and also the distance from the chassis vertical outer to the centre of the wishbone pivot hole. It should be about 1", if the aftermarket new brackets on t'Internet are correct. Here is my annotated image from Canley's web site:  ... and the original is here: www.canleyclassics.com/?archive=rotoflex-chassis-dimensionsDo you know anyone with a Vitesse Mk2 chassis, so that I can compare? Thanks, Chris |

| |

|

|

|

|

|

|

|

|

Vitesse Mk2 should be exactly the same….. I have one of those too, but as a complete working car so trickier to measure….

Measuring from our jig (having checked it still fits!)

Measurement between the pivot point centres is 625mm (24.606”)

Width between outer edges of chassis rails at the front edges of the brackets is 574mm (22.60”)

Vertical face of chassis rail to hole centres is between 26 and 26.5mm with the front nearer 26 and the rear nearer 26.5.

Hope this helps

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

|

Hum... I wonder what the factory tolerances were...

The stated rear camber for a GT6 is between 0 and 1 deg positive. That's quite a range!

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,872

Club RR Member Number: 39

|

|

|

|

Hum... I wonder what the factory tolerances were... The stated rear camber for a GT6 is between 0 and 1 deg positive. That's quite a range! All of them or just the MK2 Roto? |

| |

|

|

|

|

|

|

|

Hum... I wonder what the factory tolerances were... The stated rear camber for a GT6 is between 0 and 1 deg positive. That's quite a range! All of them or just the MK2 Roto? Just the Mk2/early Mk3 roto. I think the swing axle/swing spring variants are much more aggressive, although I must admit I haven't paid a great deal of attention to them. |

| |

|

|

|

|

|

|

|

Vitesse Mk2 should be exactly the same….. I have one of those too, but as a complete working car so trickier to measure…. Measuring from our jig (having checked it still fits!) Measurement between the pivot point centres is 625mm (24.606”) Width between outer edges of chassis rails at the front edges of the brackets is 574mm (22.60”) Vertical face of chassis rail to hole centres is between 26 and 26.5mm with the front nearer 26 and the rear nearer 26.5. Hope this helps Nick Thanks Nick, Those dimensions confirm the bad news that my brackets are indeed 1/4" too far out in terms of the pivot offset from the chassis rail. The aftermarket brackets from Canley/Rimmer/Paddock are correct at approx 1" offset, as per your measurements. I cannot understand how I went so wrong with my brackets. I was loaned a set, cut from what I believed to be a genuine Vitesse 2L Mk2 chassis and I copied them onto graph paper before sending them back. This was way back in 1988 and I was only 24 years old. So you might think a youthful mistake, but I was just as fastidious an engineer back then as I am now. All I can think is that the brackets I copied were not truly genuine and/or they had been modified and carefully tidied up so that the car was set to more -ve camber? Anyway, it is too late in the day to weld up and re-drill my brackets as the car is almost complete and the chassis is painted and waxoyled. The extra 1/4" offset would explain the more than normal -ve camber when using the standard hole height and also why it goes bonkers -ve if I use the 44mm lower Eickoff hole. I now have adjustable wishbones, so I can compensate for the mistake in the offset by shortening the wishbone from standard. Not ideal because the GT6 rear suspension is already compromised by having shorter lower arms than the upper 'arms' (spring). The opposite of good practice for roll characteristics. This year I want to get the car on the road and drive the flippin' thing, albeit in primer, so that I can check all systems are good. Next year, the tub will come off the chassis for a paint job. I may then take the opportunity to re-position the wishbone bracket holes , or maybe not... Cheers, Chris |

| |

|

|

|

|

|

|

|

|

If it helps the shortness of the lower wishbones (or rather their angle) is part of the compensation for the length of the upper ones. You still get a good camber curve despite the arm lengths being the wrong way round, at the expense of a higher roll centre and more jacking forces.

You aren't going to solve the roll centre height without de-angling the lower wishbones and losing some of that curve (or, like you've done, decambering the spring). To an extent it's a trade off with the GT6 setup between good camber curves and a low roll centre. Can't get one without the other unless you do away with the leaf spring as the upper link (making it the lower link is a consideration I've had recently, but like you I'm too far along the road to be making drastic changes)

|

| |

|

|

|

|

|

|

|

|

FWIW, my Vitesse, which is standard Triumph geometry-wise, other than a tired spring and telescopic dampers, is a sweet handling car even on the limit, without the traditionally claimed murderous tendencies. Most of the effort there has been put in up front to try and get it to turn in.

My GT6 has not been nearly so extensively tested, but seems ok so far. Having considerably less weight up front, as you do, should definitely make it easier to get it to turn in!

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

FWIW, my Vitesse, which is standard Triumph geometry-wise, other than a tired spring and telescopic dampers, is a sweet handling car even on the limit, without the traditionally claimed murderous tendencies. Most of the effort there has been put in up front to try and get it to turn in. My GT6 has not been nearly so extensively tested, but seems ok so far. Having considerably less weight up front, as you do, should definitely make it easier to get it to turn in! Nick Ah, yes, it's worth mentioning that these are mainly motorsport considerations, and why you don't tend to see lots of GT6s at the pointy end of grids with all the Elans and Minis and Imps. Perfectly good for a road setup  perfectly good for a motorsport setup too, just has some limitations other setups don't. |

| |

|

|

|

|

here you go

here you go