|

|

|

|

|

|

Not much progress last few days as I have been getting on with building up an engine for a customer, also waiting for all the parts I ordered to arrive. Just before close of play today I decided to change the rumbling front wheel bearing. Always a horrible job as the strut seems to be designed so it is impossible to support it and press the old bearing out.

This one wasn't too bad: I used the old trick of running a bead of weld round the inside of the outer race. The weld shrinks as it cools, so the race comes out with minimal effort. I then cut a slot in the race, used it to press the new bearing into its housing, popped in the circlip and placed the drive flange on the hydraulic press, face down, so I could press the inner bearing race onto it.

And that is how I discovered that Saxo VTR struts have two alternate internal diameters of front wheel bearings: 35mm and 37mm. This alone tells you that the Saxo is a French car: no-one else does stuff like this. Correct size wheel bearing now on order: at least the one that is in there should come out easily.

|

| |

|

|

|

|

|

|

|

|

|

The Thing is now back on four wheels and I spent last Saturday welding new metal into the offside front corner of the passenger compartment. Amazed just how much seam sealant Citroen had to use on these: very similar to my old Land Rover Discovery with ill-fitting panels tacked together and a big dollop of sealant to stop the water getting in. The rot had eaten a fair way into the floorpan and there was some nastiness in the lower outer corner of the footwell which I found by accident. All nice and strong now, but it shows just how far rust can spread underneath factory underseal without being visible until the whole thing falls to bits. Drivers side strut went together with the new bearing, AX GTi spring and Bilstein shock insert. It seems quite stiff compared to the old strut but I'll wait till the engine and gearbox are back in before I start worrying about ride height. Unfortunately no photos of the AX right now as I ran over my phone yesterday with a Land Rover (left it on the front bumper while doing brake tests in the yard) and it went off like a small bomb. I'm now even more unconvinced about battery powered cars than I was before.  |

| |

|

|

|

|

|

Feb 13, 2022 11:08:47 GMT

|

Another day, another parts purchasing fail. Who knew there were two different clutches for the Saxo VTR, with different bolt and dowel spacings? Certainly not the online retailers who are selling clutches as "ffits all Saxo VTR 1997-2004". A bit of research comes up with Jan 2001 as the change point. So my plan to fit the engine and gearbox this morning lies in ruins. What chance that the place I bought the clutch from will take it back? I'm not holding my breath especially as I couldn't find the Stanley knife so I opened the box with my bare hands. Grrr. If anyone wants a Valeo 821341 clutch cheap, message me. Anyway, here are a few photos showing my pitiful progress on a project I was hoping to have drivable two weeks ago...    Now off to overhaul the front calipers. I wonder if the seal kit is the correct one? If I have one piece of advice for anyone else doing this conversion, it is this: source all your bits from a single donor vehicle for which you have the reg and VIN number. I've been around French cars long enough to know that PSA alter part dimensions randomly just for fun. |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Member is Online

Club RR Member Number: 77

Member is Online

|

1996 Citroen AX VTRmk2cossie

@mk2cossie

Club Retro Rides Member 77

|

Feb 13, 2022 11:35:44 GMT

|

I think it depends which way the wind was blowing at the factories as to what parts they fit to PSA stuff  I spent 7 years at a Peugeot dealership, and it was a nightmare with brake parts on vehicles less than a year old  |

| |

|

|

|

|

|

Feb 13, 2022 13:35:06 GMT

|

|

Front brake pads that I bought, listed as Saxo VTR all years: right or wrong part? I think you can guess. In a rare piece of good luck the VTR calipers had brand new pads in them anyway. In an even rarer piece of good luck the seal kit is the correct one so my AX now has front brakes. Hoses seem a bit short on full lock but there is no engine or gearbox in at the moment so the struts are at full travel. TBH if you find yourself airborne on full lock, stretched brake hoses are the least of your worries.

I almost rolled a Toyota Cressida doing just that. I was 15, my Dad was teaching me to drive on a gravel road, and the car was the property of a Middle Eastern government. I came over a crest much too fast, got airborne, saw a sharp right hand bend immediately ahead, and started turning the steering wheel before the front wheels came back down to earth. How it didn't roll I know not, but that was my last driving lesson for a while.

|

| |

|

|

|

|

|

Feb 19, 2022 13:24:23 GMT

|

I have engine and gearbox!  Went in with no bother at all, I have hooked up the throttle cable, clutch and gear linkages so I can now sit in the vehicle and make "brum brum" noises while pretending to drive round the Nurburgring. At least I could if it had any seats. Throttle cable is far too long, need to see if the Saxo cable has the same fitting as the AX at the pedal end. Of course fitting the engine has thrown up a couple of issues, the main one is that there isn't any room for a radiator. My Saxo engine has the late "close coupled" cat, big dustbin shaped thing exactly where the filler is on my new AX GTi rad. Due to the age of the vehicle I need a cat of some kind, the obvious answer is a 4-1 stainless manifold and a Mk1 Saxo cat underneath (if it fits). Question - are the stainless manifolds being sold on Ebay for £140 any good? Things are usually cheap for a reason and I wouldn't fancy trying to make something like that for £140. The Piper one is somewhere north of £500. Next job is to look at the driveshafts and ARB, see if I can get all the big bits of metal at the front end in place this afternoon. What will go wrong next? I should have known that all the Internet experts who say the VTR engine "just drops straight in" are basically lying. Same thing in the Land Rover world with 200/300TDi conversions. It's not that simple. |

| |

|

|

|

|

|

Feb 19, 2022 22:10:02 GMT

|

|

Can’t speak for the Citroen manifolds specifically, but we recently bought one for a Suzuki Swift for about the same money from an eBay seller and it is a really nice bit of work. No idea how they did it for the money.

Nick

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

More progress of sorts. The Saxo VTR driveshafts went in easily enough, once I had worked out that the bearing carrier on the offside has to be separated from the driveshaft and bolted to the block before the driveshaft goes on. I then spent far too long trying to wrestle the anti roll bar into place: it takes a really awkward path over the top of the wishbones and there appears to be only one exact way to get it in. No excuses for what happened next other than poor lighting as I was in a dark corner of the workshop: I fitted one of the end clamps upside-down, and when I torqued down the bolts it fractured.  By this time I was already in trouble. I suspect the VTR outer CV joints are a larger diameter than the lesser cars: the gaiter rubs against the clamp bolts on full lock and will very quickly wear through it. The Saxo VTR appears to have had a different ARB design with drop links attached to the struts. That should cure the clearance issue on the CV boot: what worries me a little is that the VTR also had a different design of lower wishbone (steel tube rather than cast) and I don't know why. Clearance for the ARB? Only one way to find out... Getting to the stage now where I need to make a trip to a breakers yard, I still need a 4 stud drum braked back axle, preferably one with shot bearings for little money, and now an ARB as well. |

| |

|

|

|

|

|

Feb 23, 2022 20:05:20 GMT

|

Shiny new manifold arrived very quickly and I had an hour spare at the end of today so...  It fits! Clearance on the radiator is a bit tight, might need a bit of reflective foil to protect the plastic. I had to cut the dipstick tube in half and sleeve it with fuel hose, couldn't see any way to fit it in one piece. Manifold looks a nice tidy piece of work. I'll need a slimline fan as the old AX one fouls the thermostat cover, Saxo housing looks to be a slightly different design to the AX.  Bullet dodged. When I took the heatshield off the old manifold it had a large crack in it.  The old cat has O2 sensors both ends of it (presumably to monitor for cat failure by comparing the two), the manifold has two bosses so I will end up with both sensors upstream of the cat. Can't see this being a problem in practice although Greta wouldn't approve. I can at last start to think about getting the thing running before the end of the month. |

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

1996 Citroen AX VTR75swb

@75swb

Club Retro Rides Member 181

|

|

|

|

Manifold looks nice. How's the quality?

|

| |

|

|

|

|

|

|

|

Feb 25, 2022 19:43:47 GMT

|

Manifold looks nice. How's the quality? It looks really nice, very good clean welding and fitted perfectly. I'll wait and see if it cracks when it gets hot, but so far it looks incredible value. Did a couple more little bits this afternoon, got the starter motor and cables in and plumbed up the cooling system. My new AX GTi bottom rad hose didn't fit (of course) so I made up a hose using part of the AX hose and part of the one that came with the Saxo engine. The Saxo top hose and AX heater hoses needed a bit of alteration but everything is now connected and looks fine. Fuel system next. |

| |

|

|

|

|

|

|

|

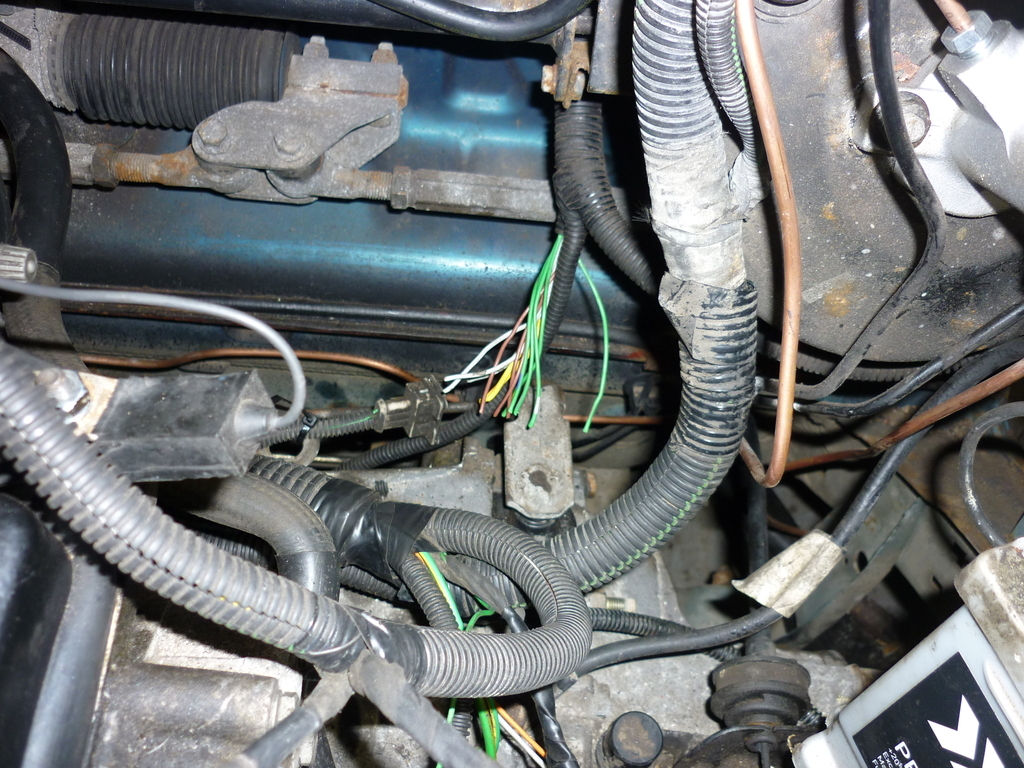

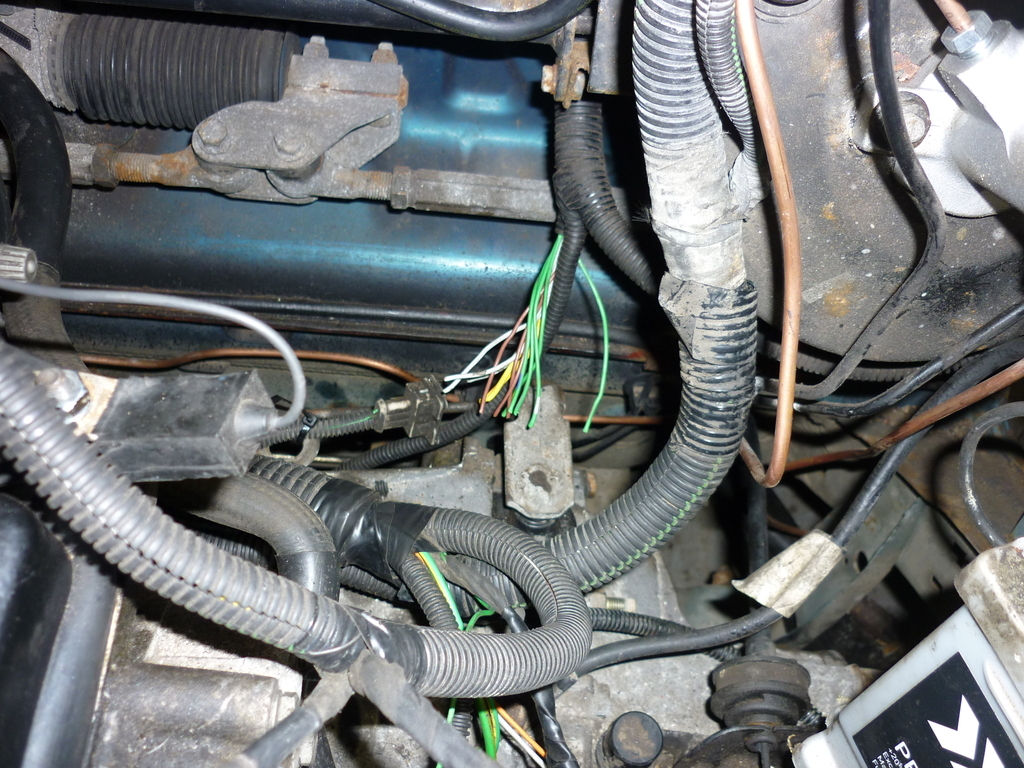

This project is now getting into the danger zone. The bit where you have about 10,000 issues to solve, struggling to find time to work on it, and then you lose interest and stick it in a corner for five years before selling it. Last couple of days I have been tackling the fuel system and trying to make sense of the engine bay wiring. Fuel first: I got the fuel tank back in but can't remember exactly where the breather and vapour lines sit. There is a plastic canister in the filler neck with some sort of plastic clip which doesn't marry up to anything. At the front of the wheelarch are two pipes (one to the tank, the other running up to the filler neck) and a T connector. The third "leg" of the connector waas blocked with mud: should it be open, or am I missing a bit of pipe? Also the pipe from the tank seems far too long given where the T connector sits. Grrr. Other fuel issues: the filler neck has a steel ring for the cap, which has rotted. I hope I can get a new one.  According to the Haynes book of words and pictures, later VTR engines like mine don't have a fuel return line which explains why I could only find one port on the fuel rail. Fine, but it turns out these engines don't have a pressure regulator on the fuel rail either. It's on top of the tank, where there isn't any space in an AX. So I need an in-line regulator in the engine bay. Hopefully once I have that sorted everything will fall into place, but I might replace all the rubber fuel hoses as they will be upstream of the regulator. Wiring: I went through the Saxo engine loom and taped up the scruffy bits (except one which I missed, spot the blue tape). It all went back on fine, with a few P-clips to stop it flapping around. ECU plate fits snugly onto the AX inner wing with very slight modification.  Now to connect it all up. Err... To start with, I'm pretty good on British vehicle electrics, but the wiring diagrams in the Haynes manual make no sense to me at all. They don't actually show the connectors, which are kind of important when you are trying to splice together loom sections for two different vehicles. I found online a connector diagram for a 106 GTi which may or may not be useful. I can't find the Haynes AX manual that I was sure I had. That shouldn't matter as I found a list of pinouts for the AX main loom to engine connector, but by that time I had already cut off the connector to make it easier to decipher the wire colours. AX wires are all solid coloured with a small stripe at each end for the secondary colour. And they use black for power feeds.  So I have a lot of work to do before I can start it up. Looks like the AX10 cat and exhaust will bolt straight up to my stainless manifold for first test run: I'm not spending money on a decent exhaust until I have heard this thing run. Oh, and I found some more rust when I removed the plastic mudshield on the offside chassis leg. Nothing disastrous but I thought I was done with welding.  In other news, I emailed three PSA axle rebuilders about having my AX axle overhauled and fitted with longer stub axles, and none of them bothered to reply. Same with the breakers I contacted about a Saxo / 106 drum rear axle to give me the brakes and stub axles I need. I'll get there in the end but this little car is fighting me. I honestly thought this conversion would be a lot easier than it is turning out to be: massive respect to all the people on here who are working on serious projects, not just fitting a slightly bigger engine from the same family. |

| |

|

|

|

|

|

|

|

|

Good effort fella - great little cars - with all the foibles one would expect of a French motor!!

Don't give in to despair - it'll be worth it in the end when you get to rag it about.

Plus it's making for an entertaining read,and there is curse word all else to do with the weather being so wibblepoo, so it'd be really selfish of yiu to give up now & not let us see the finished article.

|

| |

|

|

|

|

|

|

|

|

|

| |

Sometimes, others may not understand why you like a car so much. Sometimes, you may not even understand why you like a car so much. But none of that matters; all that matters is that you like the car, and having it makes you happy.

|

|

|

|

|

|

|

Similar but not quite the same, looks like this one sticks out a bit, the AX ring is flush with the surround. Thanks for posting though. I might end up having to repair the one I have, I reckon I can cut off the rusted outer portion and maybe braze on a new one. |

| |

|

|

|

|

|

|

|

|

Starting to make a little bit of progress today. I have identified and traced about half the wires on the AX main body loom where it connects to the engine loom. At least a couple of the ones left I suspect are for the immobiliser and one will be for the "check engine" light, which just leaves the fuel pump feed to puzzle over.

I had a lucky break when I found a diagram for the engine harness to body connector pins which matched up to the connector I have (late 3 plug ECU, 36 pin connector). That has saved me a huge amount of time: I had downloaded the factory wiring diagrams for the Saxo, but without the Citroen reference number it is almost impossible to find the correct diagram. Haynes manuals are near enough useless for my purposes: for a Saxo you need the schematic and loom diagrams, and the Haynes AX manual doesn't cover cars as late as mine.

A couple more hours detective work and I should have a dash that lights up and hopefully a fuel pump as well. Getting there slowly...

|

| |

|

|

steveg

Posted a lot

Posts: 1,586

|

|

|

|

|

I've messed with AX rear beams in the past and found it's possible to knock the stub axles out of the arms so you can swap them over. What I haven't worked out is why I had to do it ! I think it was so I could go from a 4 stud drum to the AX 3 stud one as I bought a replacement rear beam from a breakers so I could rebuild it. I thought the arms were the same and it was just the drums or disc and hub that made the difference. Rebuilding the axle once you have all the parts wasn't too bad the problem you can get is if the main pivot pin is damaged as you then have to get a replacement centre section.

I spotted the picture of the broken ARB clamp, I did the same on Friday fitting new arms on our Saxo. I'd already broken the bolt and thought a little tap would get it off ! Forgot they were alloy but had a spare in a box of bit's fortunately.

|

| |

|

|

|

|

|

|

|

But I now need to decide what to do with the load sensing bias valve on the back axle. It looks like it has been leaking brake fluid. I know what it is supposed to do, but do I need one? The AX axle doesn't have one, not sure whether this is just some piece of safety legislation that came in between the AX and Saxo, or because the Saxo has discs all round. Anyone know for sure whether I need it? I'd say that if this going to be a road car, then you ought do fit one. While it is true to say that it compensates for weight in the rear of the car in a static way, it also does a job dynamically when braking. As weight shifts forward, it reduces brake pressure at the rear to try and stop the wheels locking. You can of course do some test stops and fit a proportioning valve, but that will not provide optimum braking in all conditions as obviously it's fixed, not dynamic. |

| |

|

|

|

|

|

Mar 10, 2022 10:23:24 GMT

|

Does anyone know if a Mk1 VTR fuel rail and injectors will fit a Mk2 engine? Fuel pressure regulator is turning out to be a nightmare: the one I bought is designed to fit in the return line and maintain a constant pressure in the fuel rail regardless of manifold pressure/vacuum. Problem with that is that the Mk2 VTR doesn't have a return line. The Mk1 has the FPR built into the fuel rail. I can't even find a photo of the tank-mounted Mk2 FPR, never mind anyone who has one for sale. I can't find an aftermarket FPR designed to regulate fuel pressure on the inlet side of the fuel rail as the original Citroen one does. Any suggestions anyone? I've seen a few posts from people struggling with overfuelling on VTR conversions and I suspect the FPR (or lack of it) might be the common factor. It's an easy thing to overlook if you have just been told that the VTR lump "drops straight in". On the positive side I've found the body loom connector for the fuel pump and check engine light feeds. Next to the offside headlamp of course, opposite corner of the engine bay from the main body loom connector.. How silly of me not to have looked there first  French cars are special. |

| |

|

|

|

|

|

Mar 10, 2022 12:48:58 GMT

|

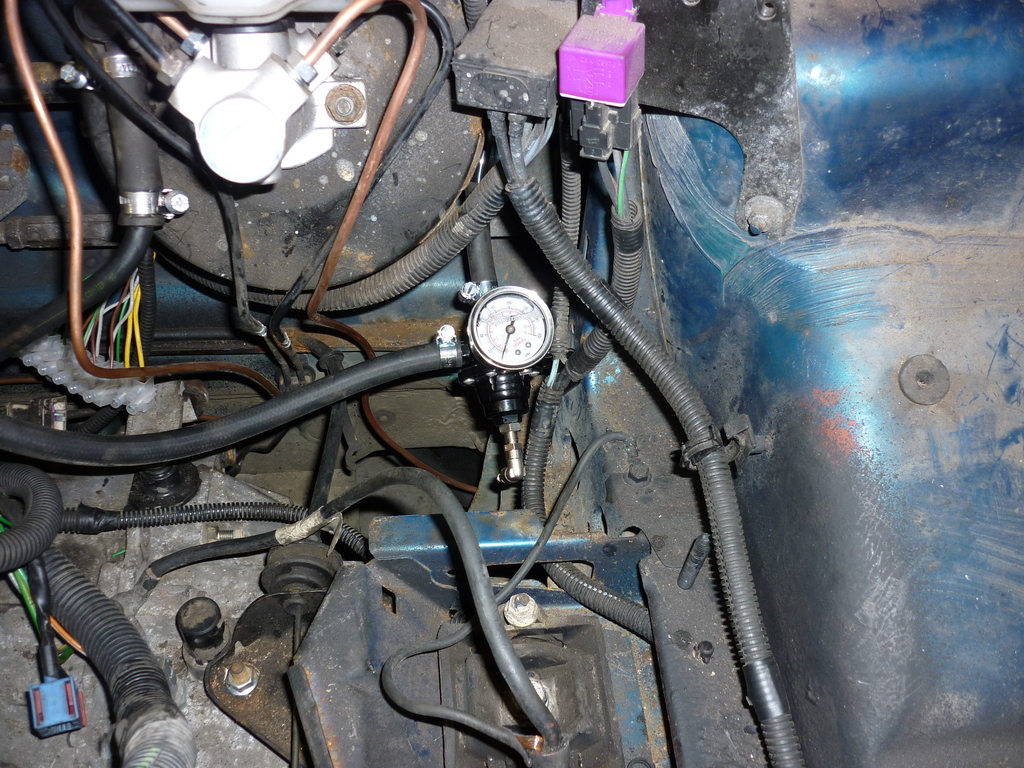

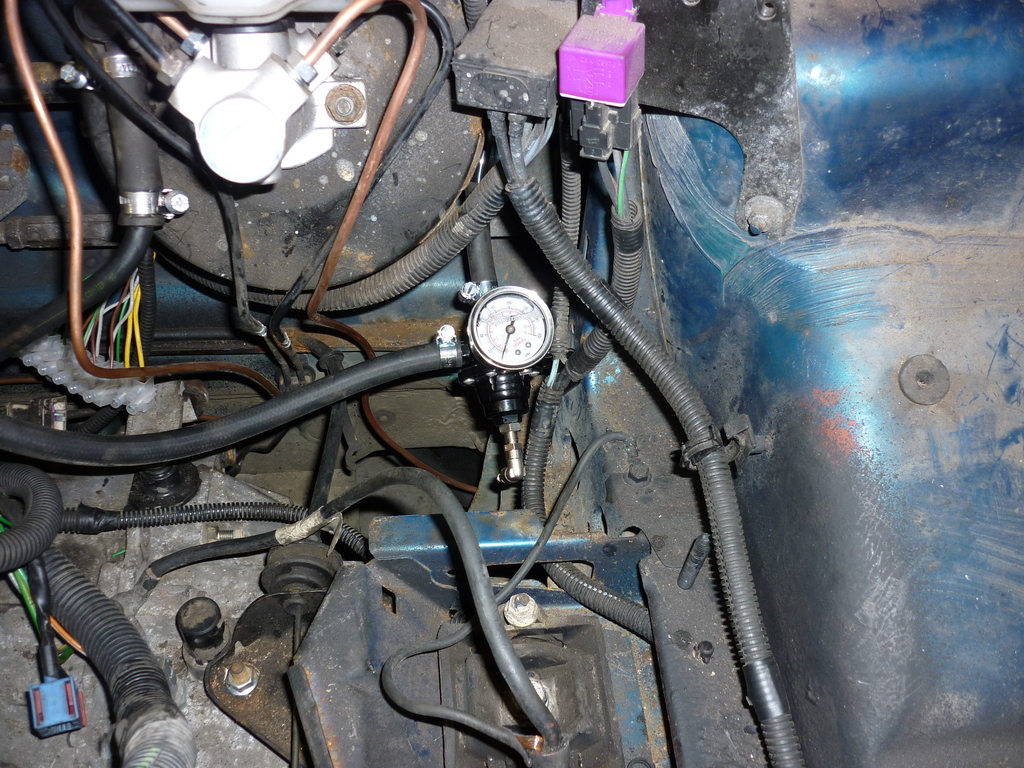

I might have found an answer. On the end of the Mk2 fuel rail, where the FPR would sit on a Mk1, is a Schrader valve which I think is for connecting a fuel pressure test gauge. I unscrewed the core from it and now I have a fuel return.  The Ebay FPR (which claims to be Italian, but I know Chinese packaging when I see it) Tucks away nicely under the brake servo, close to where the fuel lines come through the bulkhead.  I just have to replace one elderly fuel hose length at the back of the vehicle, then I can tip in a couple of gallons, power the fuel pump and see what happens. Outside I think, with a fuel extinguisher and fire blanket handy. Far too many videos floating around of this kind of test going wrong. I'm not happy with the way the fuel feed hose connects to the fuel rail atm: it's just a smooth 8mm pipe stub intended for some kind of modern push on connector. I'v used a hose and Jubilee clip which I'm sure will hold for testing, but I really need something that is guaranteed not to come off at 2.5 bar. It would be a shame if my AX caught fire after all we have been through together. |

| |

|

|

|

|

French cars are special.

French cars are special.