|

|

|

|

|

John Cross with his VR6 turbo powered Super Retro Rally Cross Stratos has similar roof mount Intercooler RS200 As I will only have low boost I will go Water/Air intercooler as theses are more efficient / smaller so I can be more flexible as to where I mount the radiator for the intercooler, probably up front of the main radiator? Body work will be taking inspiration from there Lancia Grp 4/5 sports Prototype before they went longer wheelbase / long tail Grp5 silhouette I.e as I posted pictures before   |

| |

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,884

Club RR Member Number: 39

|

|

|

|

There is quite a bit of space in the back of the standard bodywork if you go light and exclude the internal structure for the boot - and then ventilate it.  Just me doing this then  And maybe my mate CJ |

| |

|

|

|

|

|

|

|

|

X-sport doesn’t have any boot area, it’s all open

|

| |

|

|

|

|

|

|

|

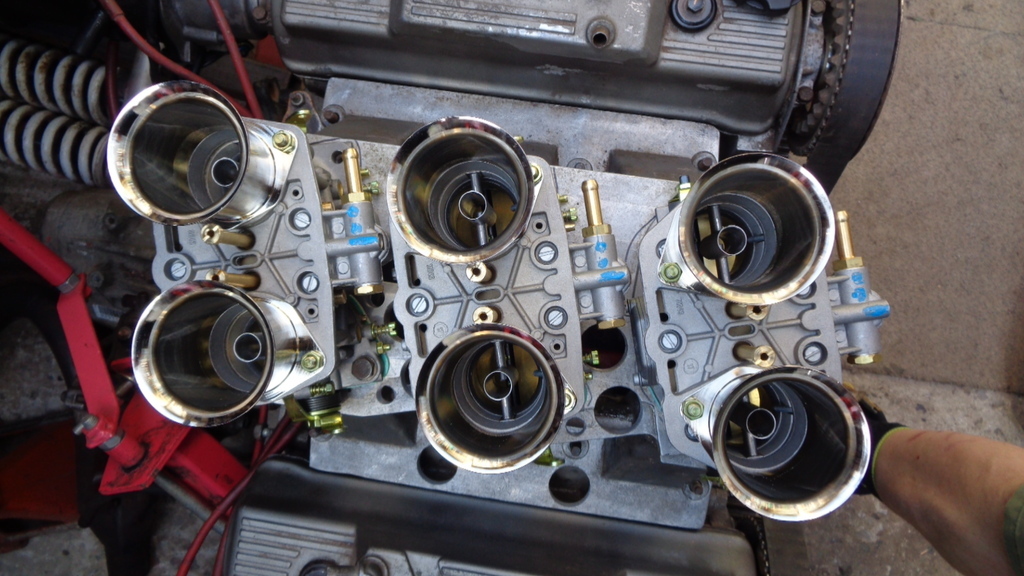

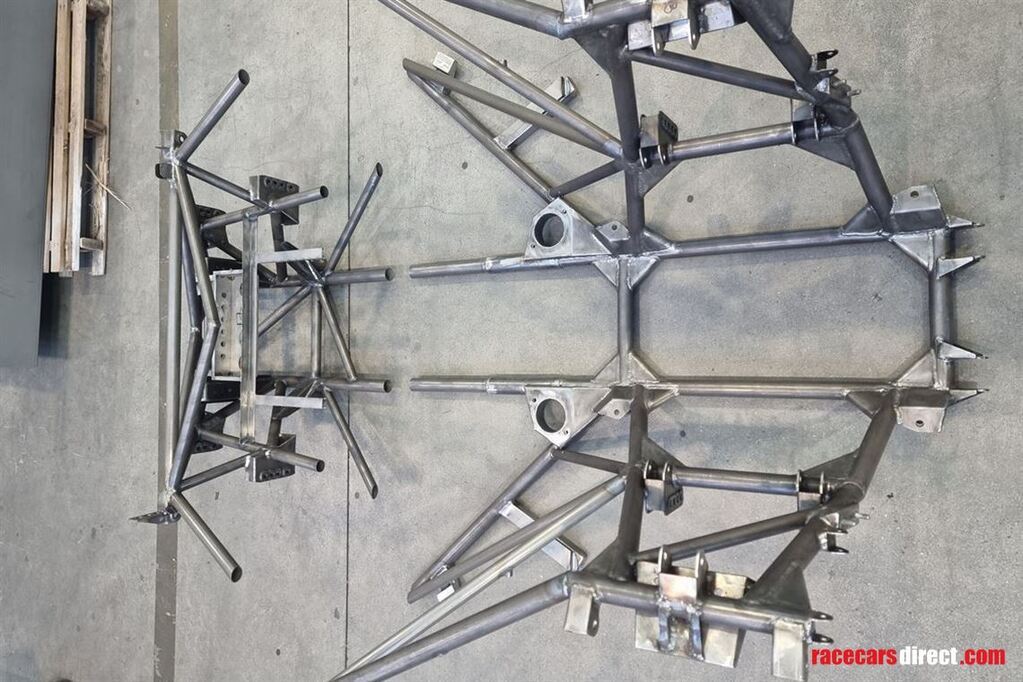

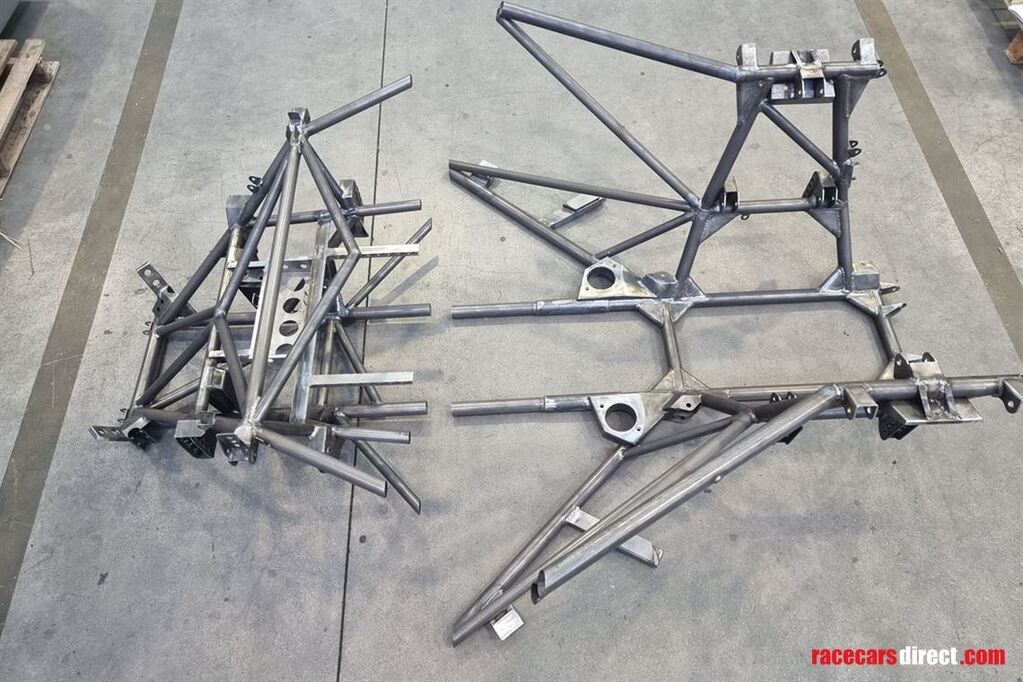

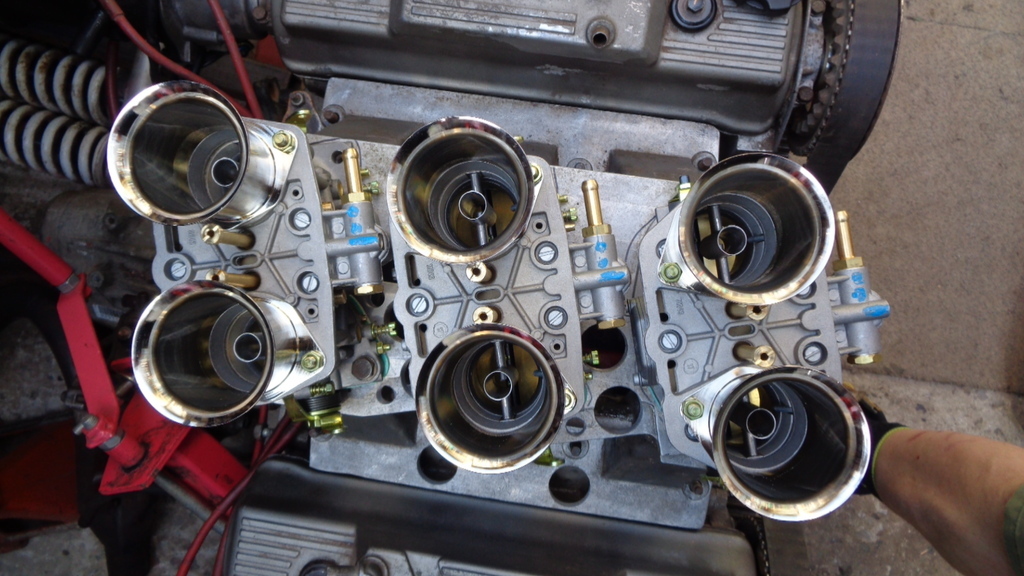

So spent a lot of mental thought and double triple measurements, quite exhausting At this point to fit correct length A-arms and mimic the rear suspension geometry of a 037 I will shift engine over to the Left 80mm and the CV flange centerline forward of the wheel center by minimum 40mm possibly 50 ? 60mm is 2degree away from maximum articulation, so 50 should be safe as that angle plain will not change except chassis engine flex which should be minimal I am rotating the front of engine up to bring the cam covers somewhat level, so I can go IDA Webers This also gives plenty room to have front track bar of rear lower A-arm to mount forward of and possibly a bit under the front right of oil pan, which will be cut short as the engine will be dry sump At this position the theoretical center of the engine cyl’s 2-5 will only be 35mm to the right of centerline Carbs should look pukka I have cut some box section to be my engine set up jig stand, I will join parts together to eliminate risk of engine toppling off them 😀 I have come with another ignition option of this Turbo blow thru IDF’s as I really want an analog car not a EFi Digital Racing HEI Buick V6 distributor (even fire version) they are self contained, coil in cap only need power wire, cut down housing weld on a machined bearing housing and take drive off front intake cam sprocket ie like the Dino, and yes has correct rotation too !!!    |

| |

|

|

sonus

Europe

Posts: 1,392

|

|

|

|

|

|

| |

Current

1968 TVR VIXEN S1 V8 Prototype

2004 TVR T350C

2017 BMW 340i

Previous

BMW 325d E91LCI - sold

Alfa Romeo GTV - sold

Citroen AX GT - at the breakers

Ford Puma 1.7 - sold

Volvo V50 2.0d - sold

MGB GT - wrecked by fire

MG ZT 1.8T - sold

VW E-golf Electric - sold

Mini Countryman 1.6D -sold

Land Rover Discovery TD5 - sold

|

|

|

|

|

|

|

I have seen that company once before X-Sport racing who I am getting my body from also have full molds for RS200 6R4 |

| |

|

|

|

|

|

|

|

Engine in set up position, only 12 degree CV inclination with Engine 60mm forward of wheel centerline Leaves enough room for 037 type suspension Going raise rear chassis frame up 50mm from center roll hope so I can fit rear diffuser, probably vent turbo outlet into the diffuser    |

| |

|

|

|

|

|

|

|

|

I have been analyzing the last 6 days exactly where but the engine, the actual balance point is somewhere close to center of last 4 cylinders

60mm Left offset visually looks good but it will be heavily weighted Left I don’t believe I could compensate with enough parts placement on right to correct it.

I will probably end up with just 25mm Left offset ?visually not as good but will be much closer to equal weight balance

I have moved the engine forward another 10mm so now it’s 70mm total forward of wheel centerline

Still safe CV angle 15 degrees

|

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,884

Club RR Member Number: 39

|

|

Mar 11, 2023 10:57:16 GMT

|

|

|

| |

|

|

|

|

|

Mar 11, 2023 12:40:21 GMT

|

Thanks, yes I think I have, I have see a few different, I follow 037 FB resource group, there’s lots of info I have obtained from them. I will not have 037 narrow rear frame width very long A arms on the rear, I can obtain the same static geometry with a little bit shorter arms, however I can use less off set wheels to gain some A arm length over normal Stratos 037 had a narrower rear Track Width v Grp4 Stratos so theirs a bit of give and take |

| |

|

|

|

|

|

|

|

Mar 11, 2023 21:08:54 GMT

|

I have been analyzing the last 6 days exactly where but the engine, the actual balance point is somewhere close to center of last 4 cylinders 60mm Left offset visually looks good but it will be heavily weighted Left I don’t believe I could compensate with enough parts placement on right to correct it. I will probably end up with just 25mm Left offset ?visually not as good but will be much closer to equal weight balance I have moved the engine forward another 10mm so now it’s 70mm total forward of wheel centerline Still safe CV angle 15 degrees I'm sure you've already considered this, but have you taken into account the weight of the driver in the finished car; would that not help with the weight balance? Of course this only works if the car is going to be RHD; LHD only exacerbates the issue. |

| |

|

|

|

|

|

|

|

I have been analyzing the last 6 days exactly where but the engine, the actual balance point is somewhere close to center of last 4 cylinders 60mm Left offset visually looks good but it will be heavily weighted Left I don’t believe I could compensate with enough parts placement on right to correct it. I will probably end up with just 25mm Left offset ?visually not as good but will be much closer to equal weight balance I have moved the engine forward another 10mm so now it’s 70mm total forward of wheel centerline Still safe CV angle 15 degrees I'm sure you've already considered this, but have you taken into account the weight of the driver in the finished car; would that not help with the weight balance? Of course this only works if the car is going to be RHD; LHD only exacerbates the issue. Yes I have because it’s LHD it makes it worse, I am a flyweight but still I will need everything I can mount to be on the RH side hence screw looks engine has to go as far right as possible I believe engine is balanced LH RH if CV flanges are centered but that is a little too far RH so probably 30-35mm LH will be fine so I’m mainly counter balancing my weight |

| |

|

|

|

|

|

Mar 12, 2023 10:04:07 GMT

|

|

With the flanges they made the driveshafts equal length to limit torquesteer. Interesting if alfa indeed also balanced the weight lh-rh that way.🤔

|

| |

|

|

|

|

|

Mar 15, 2023 14:33:09 GMT

|

While I wait on Roof Roll bar from bender, I sent off the Alfa CF2 3-1 headers off to media blaster, they are a stainless look good enough for Turbo manifold, though I might change collector to merge type ? Onwards with something else “IDF Intake Manifold” Lots of measuring later I cam up with this skewed/ angle carb design  50x3 wall aluminum tube bore = 44mm for 44 IDF carbs, because of the tight 1 x D diameter radius, the bend will be created with “pie cut” tube Sections 2 x 15 degree segments / intake runner      Cyl intake flanges out be being water jet cut, gave the company 1 port of intake gasket as template which I have to pay CAD DFX file set cost + the flanges in 8mm thick 6082 T6 The injector cut out is eliminated on the flanges, the intake port opening will need profile grinding from flattish oval opening to just off round. Weber carb IDF flanges are available from Danst Eng’ already ordered |

| |

|

|

|

|

|

Mar 15, 2023 19:22:28 GMT

|

|

Would it make sense to make one flat plate to weld all the tubes to? Because that way the spacing is locked in and so is the level of the carbs. You could cut it into separate manifolds afterwards. Or I suppose bolt the flanges you're having cut to a similar plate.

|

| |

|

|

|

|

|

|

|

Would it make sense to make one flat plate to weld all the tubes to? Because that way the spacing is locked in and so is the level of the carbs. You could cut it into separate manifolds afterwards. Or I suppose bolt the flanges you're having cut to a similar plate. The carb flanges will be mounted to steel plate I will used the engine for alignment Intake will be matched to port using close fitting bolt holes so they line up with minimal wiggle room As the carb flange goes on last it will all be perfect Yes you could have 1 piece / cyl head however you have to also consider access to welding everything 3 manifolds makes everything easier access |

| |

|

|

|

|

|

Mar 17, 2023 10:31:47 GMT

|

Segments welded, waiting on flanges    Used 4 stage dry sump pump arrived Turned out to be a reverse/cam drive type So I have flipped pump segments so I can run normal direction via Gilmer belt drive, however I will need remote oil pressure regulators as not possible to flip end cap on the pump Still saved big chuck of cash with this used unit  |

| |

|

|

|

|

|

Mar 19, 2023 10:43:10 GMT

|

Removed engine, cut hole in jig for Differential clearance do can set engine at its final level and lowered position 35mm offset to Left = balance point at centerline Drive flanges 70mm forward of wheel = 15 degree CV shaft angle    |

| |

|

|

|

|

|

Mar 20, 2023 10:49:32 GMT

|

Back to the intake manifold 6082 T6 oval hammer form tool  Gently gently squeeze the lower tube oval. Same amount on all  Used form tool to flatten the lower edge It actually becomes D port shape which is an efficient port flow configuration   Then free hand used 1/2 round file to take off the mismatch edges for the welded sections Finished off with rotary sanding roll Leave the uniform sanding marks reduces laminar flow helps avoid fuel droplets sticking to port wall  Now back to waiting on flanges 🫴 |

| |

|

|

|

|

|

Mar 23, 2023 15:48:17 GMT

|

Peripheral Roof Bar installed today, not as tight to the roof as I was hoping but it will be ok X cross brace will go on later Now I can measure the bends for the connecting A Pillars   |

| |

|

|

|

|