Okay, fixed the computer, time for an update.

Headed down early. There was a light smattering of rain en route, but that ceased by the time I got to the car.

Swept up the work area as it was full of gravel, dirt, cigarette ends, grass cuttings etc. that had blown in.

Parked the car up in the now nice clean, grit-free(ish) carport.

Important part of the tool arsenal: Big Fan.

Slackened off the lug nuts as the car's been sat up a while. It sits on studs, hubcentric, so cracking them off with the wheel on the ground is easier than fighting with it.

Grab the axle stands and jack, and jack the car up on the frame rail.

Grab a flashlight and give up inside the wheelarch an inspection. See nothing.

Grab the Raid and give it a good squirt inside for good measure anyway.

Grab the largest socket I own for the car to undo the driveshaft spindle nut.

Like a complete plank, I've forgotten to slacken the nut off. Put the wheel back on, lower it down and crack the nut off.

As if by magic the photo progression shows the car jacked up again with the spindle nut off.

Reach around the back and undo the bolts that hold the brake calipers on.

Ziptie the caliper out of the way for now, as my main focus is the suspension.

the driver's side brake disc was rusted on quite firmly. Reached around the back and using the handle of the lump hammer, gave it a few clouts to free it off. Give it a wiggle and it comes off:

That's when

the spider was discovered, mere inches from where I'd been raching in. Black widows are aggressive and will often jump and bite anything they think is too close.

Gave it a prod with a long screwdriver, it flailed a little, got a neat douse of the nearest thing to hand (carb cleaner). It fell to the floor and was promptly stamped on:

With the big nastie out of the way I turned my attention to the plan du jour: Replacing the knackered bits:

Crack out the Sykes-Pickavant spring compressors I dragged across here a while ago and wind them in at the best location on the spring available:

With the tension off the bolts, I undo the two nuts that hold the bottom of the strut to the hub:

That allowed me to pop the hub out.

Give it a wiggle and the thing comes off- no point undoing the steering joint. Those are a bit fusty but otherwise ok, no point in disturbing them. they are on the to-do list though.

The first shiny new thing! Lower balljoint. Genuine Renault part- hopefully it should last.

Clean up the hole and push it into position, locking it in with a new bolt. Considerable improvement over the old one.

Next up on the list- anti-roll bar bushes on the outer edges. These were squeak-clunk-thump before. I can see why.

I've seen worse, but it's definitely seen better days. It's in an exposed location too, so best to change it out:

The reinforcement plate was at one point cadmium-coated (that funny yellow/purple coating) but that had long since gone through and become rusty. Gave it a rub down and applied a coat of rust-killing paint. I need to buy something that's not yellow though...

Cleaned many years of

merde off the wishbone.

Three minutes later, the paint is dry enough to handle (yup, warm weather) and put in place. Tasteful...

Bolt the anti-roll-bar back in, which was a bit of a fight.

Reassemble the hub onto the wishbone, fight to get the bolts in as the strut has expanded under its internal pressure off the spring dish. Torque the new bolts up:

Give the hub face a rub down with some 800-grit to clear the rust:

A light wipe of a greasy finger should help prevent it from sticking so badly in the future:

Put the disc back on, and feel that it sits true. No discernable movement, which is nice. Put the washer back on after a clean and a new Nyloc spindle nut:

Undo the caliper and give it a brief inspection, and try figure out how it comes apart.

After finding that the slider pins undo to break the caliper apart, remove all the old nasty rubber bits:

The piston looking good, moving freely too.

Stick the new dust boot on:

And the new rubber bushings and nylon anti-friction pieces:

Give the pins a wipe over with petrol and all the old gunge comes off:

All torqued up and back on the hub.

Grubby hands! Sign that good things are happening.

Bring the wheel down into light contact with the ground and tighten up the spindle nut to correctly load the bearing:

Dump it onto the floor and spin it round to start the other side.

Chocks, axle stands and jack. Trying to keep a safe working environment.

The passenger side is much of the same, just repeated. Took it all to bits:

Spring compressors on again to take the load off the hub bolts:

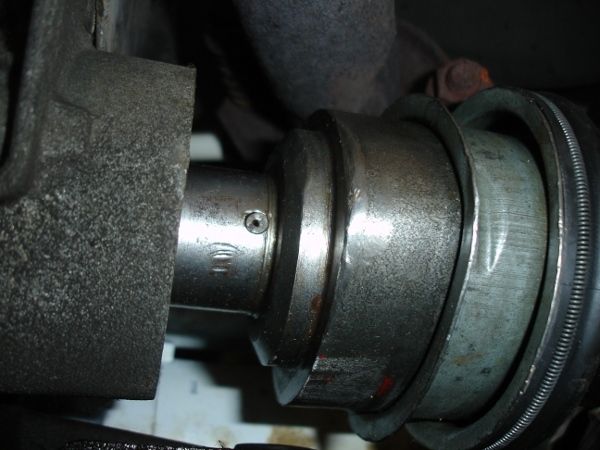

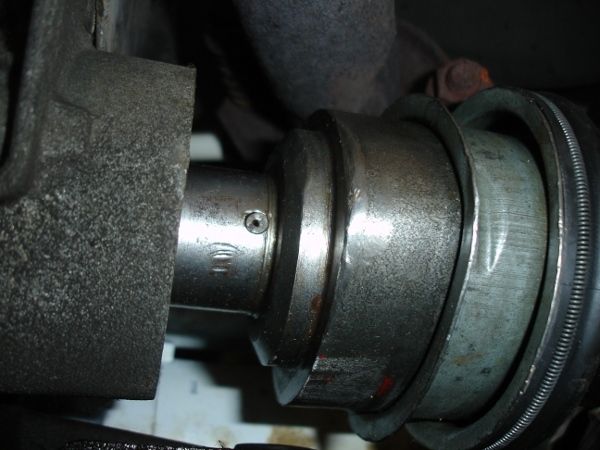

Lift the hub off. This side's a little different:

One generally knackered driveshaft:

It all looks pretty good back up under there. The wet on the back of the block is Raid bug spray

Spiders get everywhere. This anti-roll bar bush was covered in lots of little ones. They were evicted and the bush replaced.

Shiny new bits again! Rebuilt drive shaft. Not all clunks and slop, unlike the old one.

Awesome photography skills, laying under the car in the dark and cobwebs, but you can see light through the pin holes. these are (don't know why) drilled offset, so one way it fits, the other way not quite, by a fraction.

After ten minutes panicked rummaging, I found the roll pin for it:

Out came the punch and hammer, and it was driven snugly into place:

Which meant the rest of it could be assembled with new bits. Et voila! Forty minutes compressed into a very small time frame

Back down on all four wheels, with some 'interesting' negative camber, due to being brought down off the jack. this cleared once the car moved six inches.

With the day drawing to a successful close, I decided on a small job- fit the temperature switch for the radiator fan (shiny bit with the red wire)

Idled the car up to temperature- the thermostat was a bit sticky to begin with, but I hit this hot, watching the engine like a concerned father:

CLIK, WHUUUUUUUUUUU

I can feel the blast of hot air from here.

30 seconds later, the temperature's here and the fan cuts out again:

Satisfied with that, I gave it a quick test run down the street slowly. It runs and rides like a dream. the speed hump is taken with smooth grace and it has a fair bit of torque- 4th at 20 kind of torque that it just burbles along with no hint of distress. the brakes, once I'd run down the street with one foot on the brake and one on the gas are very, VERY sharp. Impressive, as they appear to be Espace in size- the anti-squeal springs in the Bendix rebuild kit were too small, and they were listed for Renault 19 16V...

Happy, I tucked it away for the night:

Headed home, happy that I'm that much further along with it now.

Rear brakes to look at soon, a couple other bits- the clip that holds the speedo cable in (gotta find it), a pipe clip or two here and there, some consumables (wiper blades etc) and it'll be ready for inspection. the gearshift needs new bushes, they look specialist, so I'm probably going to have to order those in from overseas.

Excited

--Phil