|

|

|

Feb 20, 2013 12:46:23 GMT

|

Darrylwebb - You've been very busy, so its taken you only 8 months to get that far? Hat off to you mate..... looks great. Are you going to use megasquirt ecu or some other after market? Erm.....1 year and 8 months. Progress is slow. Every item is getting attention.  I'm staying with the standard injection system. I'm not throwing out a working system I got for free, to fit something else entirely. I'm using the entire Omega loom (not just engine loom) so it makes sense to stay standard. Well done on being man enough to do upholstery. I remember going to sign up for upholstery classes so I could do the sort of work you're doing. 'cos I'm a bloke they thought I was taking the p*ss. And nice work. |

| |

|

|

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

Feb 20, 2013 14:50:07 GMT

|

|

Ha, I know what you mean. Beer drinking whilst sowing balances it out right? Thing is I'm too tight to pay 2.5k for someone else to do it, next step Knitted seat covers!!!!!

|

| |

|

|

|

|

|

Feb 20, 2013 18:29:29 GMT

|

Thing is I'm too tight to pay 2.5k for someone else to do it I'm right with you on that. Why pay someone else to do a job if you have, or can attain, the skills yourself!? |

| |

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

Feb 26, 2013 23:05:14 GMT

|

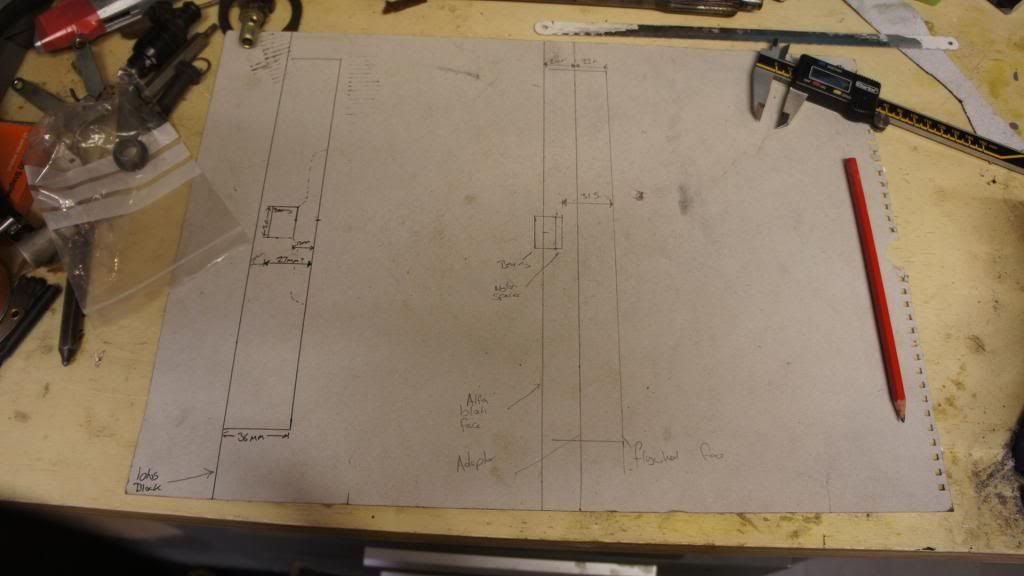

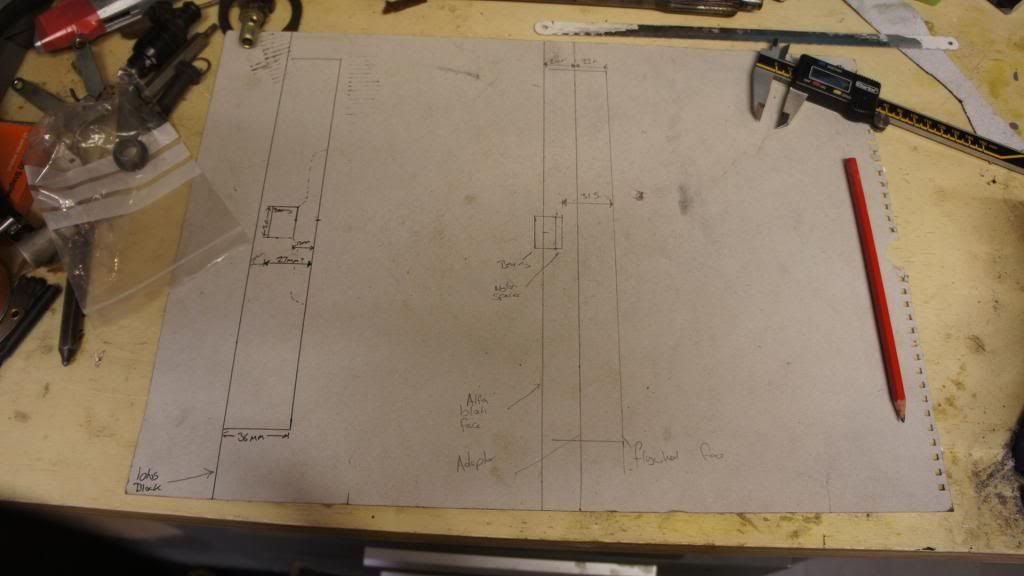

Most of the weekend was spent ordering bits and bobs such as the correct ally for the inlet runners, extra throttle bodies and material for extending the input shaft. Oh and more material, I think I may run out. First job of tonight's jobs the ITB position. I'm using Triumph daytona 959 with alloy fuel rail which are 43mm ID or maybe just a little less. This wouldnt be ideal if you were looking for increasing performance. I just want reliability, I should still get the 220bhp standard with these, maybe more. This obviously was the first ideal, issues with throttle linkage and the base of the bodies was very tight to the heads so the inlet manifold would be difficult to fabricate.  This way seems to work so much better. All I need is another fuel rail and re thread the ends. All throttle pivots running the same way so only a nice neat linkage rod on the outside.  I quite like how the bodies lean towards the back on the engine it makes for good view when stood at the rear of the car so that's staying.  Picked up the adapter tonight after work. Nice work but I begrudge handing over that sort of money, when you research the price of ally and what they actually quote you it doesn't seem correct. I suppose its time taken to position and cut from a template. Next time the jigsaw is coming out.  Marked up the holes from my template ready for drilling on the pillar drill when I do eventually spend a morning at the depot  Lastly, I got hold of an off cut on en8 bright ready for extending the input shaft then hardening.  |

| |

|

|

sonus

Europe

Posts: 1,392

|

|

Feb 27, 2013 12:44:30 GMT

|

The Alfa V6 is a thing of beauty as is the Esprit. In my opinion you are making something way greater than the sum of it's parts! I'd love a Alfa V6 powered Esprit and I think a lot of others would to if they had a way of doing it easily  |

| |

Current

1968 TVR VIXEN S1 V8 Prototype

2004 TVR T350C

2017 BMW 340i

Previous

BMW 325d E91LCI - sold

Alfa Romeo GTV - sold

Citroen AX GT - at the breakers

Ford Puma 1.7 - sold

Volvo V50 2.0d - sold

MGB GT - wrecked by fire

MG ZT 1.8T - sold

VW E-golf Electric - sold

Mini Countryman 1.6D -sold

Land Rover Discovery TD5 - sold

|

|

|

|

|

Feb 27, 2013 12:45:30 GMT

|

|

Looking very clever.

|

| |

|

|

|

|

|

Feb 27, 2013 13:32:12 GMT

|

Hey, impressed by the re-upholstering work and the engine - this the V6 will give the Esprit the noise it deserves... I have an Esprit S3 1981 and humbly suggest the following as possible ideas? 1. I think you could get away with 220 bhp with exising gearbox if you get a LSD and get some parts cryogencially treated (!) - there a guy in France www.ds-vitesse.com/ who specilizes in these boxes - you would then not have to change the hubs, drive shafts, brakes which you would need with the UN1 gearbox... might work out cheaper? 2. the tanks should not have GRP on them - they should just be metal with a rather crappy black paint (which will have rusted by now) - this is also because the foam they used to go under the tanks absorbs water and rusts the bottoms out - mine has stainless tanks now with yoga mat as the foam (I think!)... So think they have been repaired in the past? 3. when you do the interior, you could add back lighting for the window switches (the headlight switch has this so you can see how it is wired) the rest of the dash switches are the rubbish fibre optic system - similar to an early jag XJS) - I think this would look cool against the new diamond stiching. Oh you could also put in relays for the electric windows as this would improve performance (there is a guide I think on www.thelotusforums.com/forums) and mean you don't melt a switch! 4. If you are doing the seats, I would put in heated seat elements - I think you can them relatively easily and it would make a good difference in winter (if you are heater is as useless as mine!) - I would have put these on my seats but they were re-done before I got the car. You get some retro looking switches and mount them on the side of the transmission tunnel (similar to an XJS) |

| |

|

|

|

|

|

Feb 27, 2013 18:44:24 GMT

|

|

Excellent project...way to go!... i assume you've seen thishttp://www.motorgeek.com/viewtopic.php?t=9648

|

| |

I would be rich if i had not spent so much money on Cars and fast women...oh, i did waste some of it as well!

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

Feb 27, 2013 20:08:54 GMT

|

skiing - Yes I researched last year, found Harry to be very helpful. Parts are not cheap but he does have everything I need including used items  I seem to remember reading up on 220bhp is the limit for the box. For the time being I will carry out a partial strip to check and run the box as it is, oil was clean and almost no filings either. Do you think the LSD will help, I could understand if I was going to track day it but on the roads? Great tip about the switch lights mate. I was wondering what to do with the mickey mouse optics. The bins the best place for it! The seats will be going to an upholsters as I want the denser foam in the side sections. @ maybachman- its a great write up, lots involved with it. One of the reasons for keeping the original transaxle. Does anyone know a great upholsterer in the west midlands area?

|

| |

Last Edit: Feb 27, 2013 20:44:35 GMT by deanchad

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

|

|

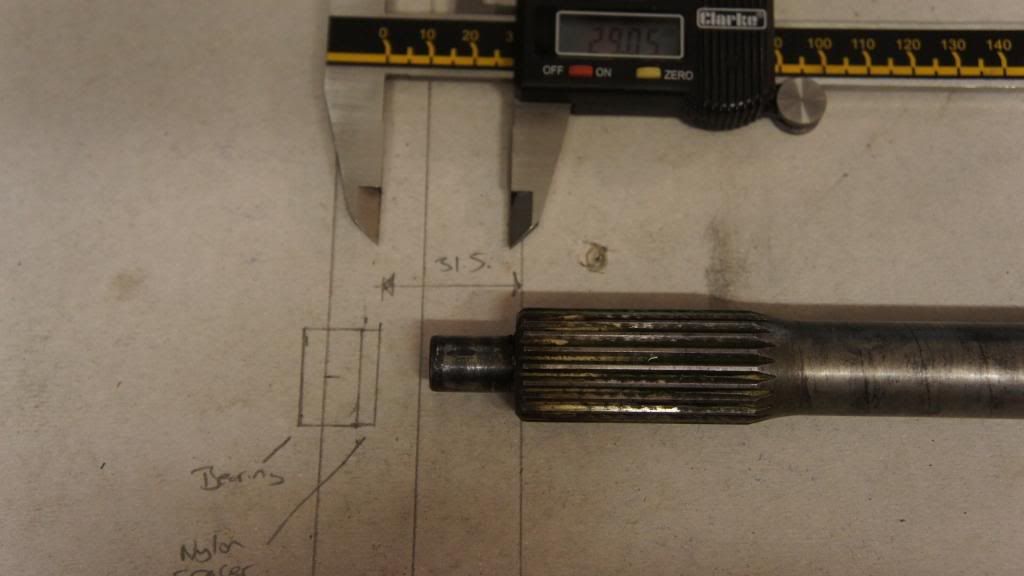

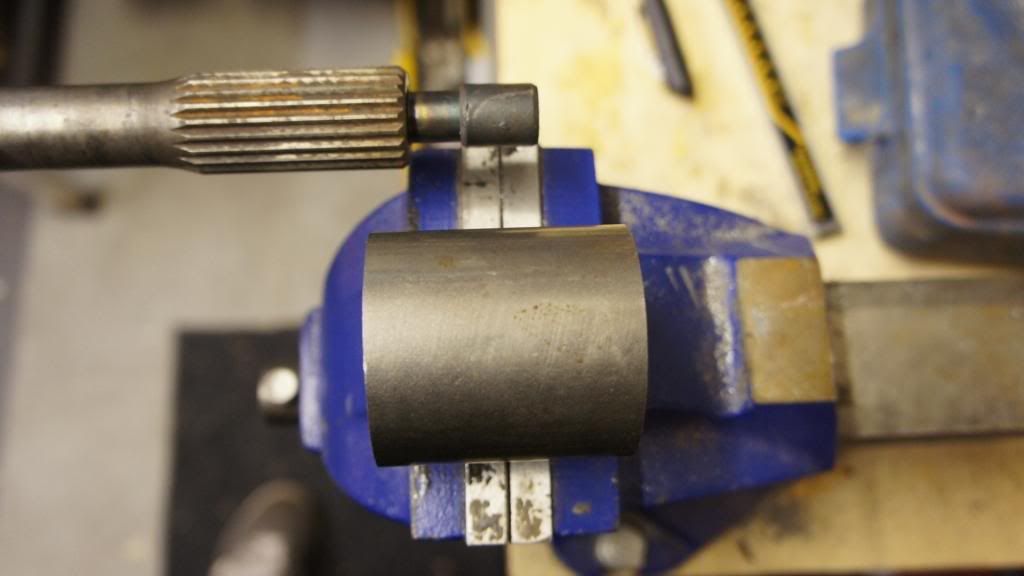

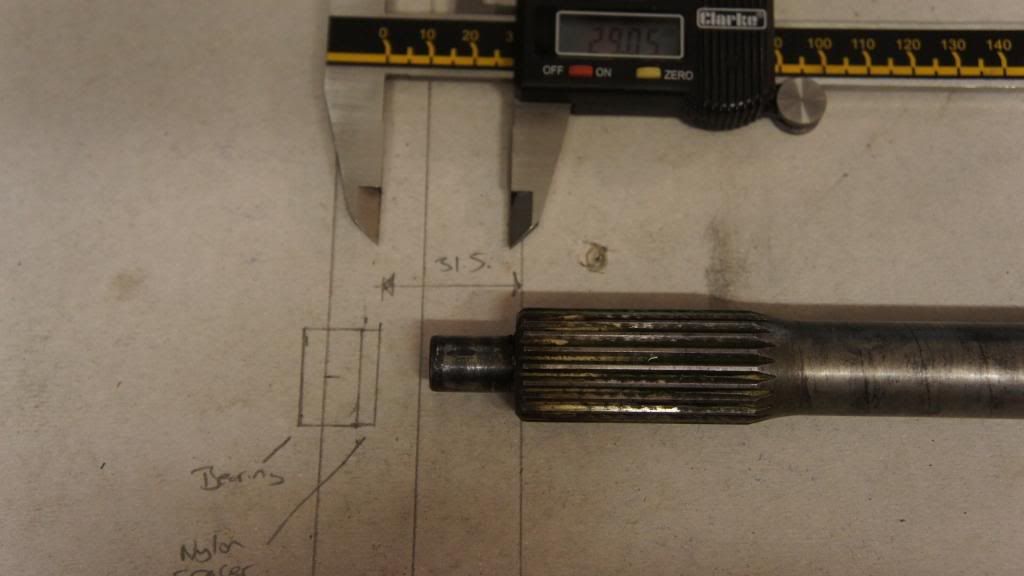

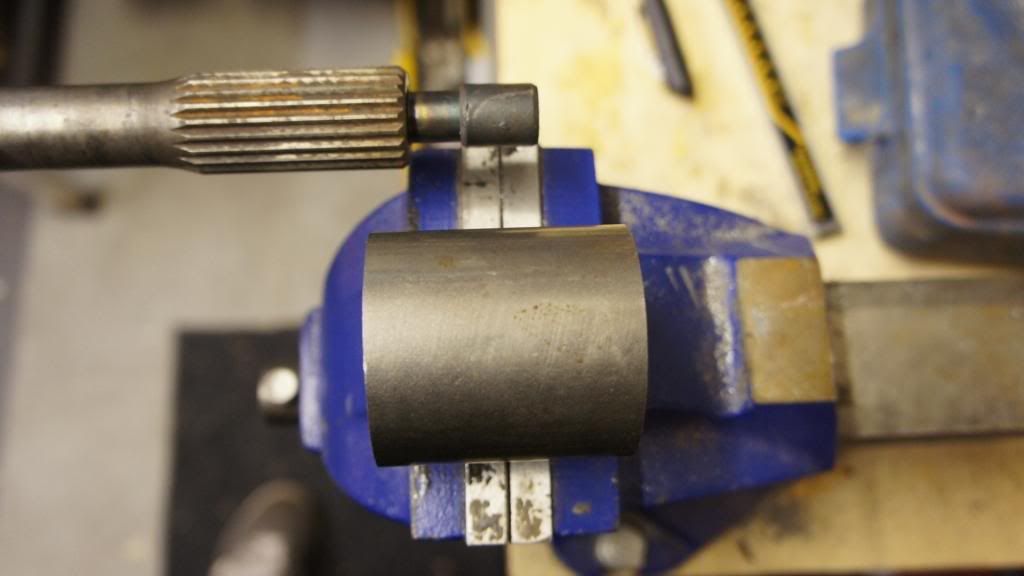

This week I'm in the workshop so in breaks, before and after work should see some bits coming together. Trying to remember which bit needed cutting and to what size had been woring around in my head. It was starting to annoy me having to go back to the engine, measure think about it then 5 minutes later totally forgetting what I had done. Needless to say, I should have done this in the first place! This shows just how much the shaft position or spigot bearing between the lotus block and alfa block differ  The extension needs to be 29mm so input shaft connects to the primary and the friction plate fits on the splines. No need to have a new shaft made   Parts needed for the extended shaft. Not cheap but available next day.  Check this out, the bearing is an exact fit in the crank shaft. Even the shoulder is perfect for the spigot to sit against. No need to make a bush for it to sit in... Thanks Alfa!  I turned down the 51mm piece of en8, bought a 6mm centering drill to start the internal collar, then used various bits up to 12mm for an interference fit, I will be using some loctite 638 to hold it tight    This weeks job. Transmission/engine strip on a 90tonne wheel loader   POOOOWWWWEEEEEEEERRRRR! 900hp, trillions of torgues! Hopefully the input shaft will be finished by Friday, then I can move on to finishing the adapter plate. more soon |

| |

|

|

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

|

|

Today has been a really good day. Not only have I been in the workshop all dry, the 3.5 tonne engine from the loader has been removed AND I finished the input shaft. Tit end extension finished with bearing surface installed. The section was hardened before pressing onto the input shaft. I forgot to a photo of the second parts of the hardening process but here is the first part anyway.   old friction plate and lotus pressure plate. These have been sold with the lotus engine so a new helix clutch cover is on its way and possibly a Renault 21 turbo friction plate will be used (235mm and 24/21t spline)  Tomorrow will be drilling more holes and ordering countersunk bolts for the gearbox adapter |

| |

|

|

|

|

|

|

|

|

Love this thread.

Id love a slammed S2 on period wheels, i can now (somehow) insure one of these, so could be a goer within the next few years.

|

| |

|

|

niwid

Posted a lot

Posts: 1,754

|

|

May 29, 2013 10:32:31 GMT

|

|

This is gonna be fantastic when it come together. Rekon it's gonna be at the Gathering again this year?

|

| |

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

|

|

|

I am hoping to get there this year, engine will be in but i'm sure the interior wont be quite finished................ updates very soon

|

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,062  Club RR Member Number: 77

Club RR Member Number: 77

|

|

|

|

We are happy for any updates with the Lotus  And i'm sure the interior will look awesome if the centre console is any thing to go by  |

| |

|

|

PhoenixCapri

West Midlands

Posts: 2,685

Club RR Member Number: 91

|

|

|

|

|

As ever this is looking great, good to see someone brave enough to extend an input shaft, most would have run away from that challenge!

|

| |

|

|

|

|

|

|

|

|

Simply awesome work. If I had a hat, it would be doffing right now

|

| |

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

|

|

PROGRESSSSSSSSS...... Things are getting done however most is unfinished! Anyway, cast your minds back ermmm a few months, I was having problems finding a larger friction plate. Well, Turns out the renault turbo plate, although the right spline and diameter, didn't quite fit?! After a few days of searching, I realise the maserati merak had the same transaxle and turns out, just the right diametre plate. A few emails to Harry at dt-vitesse and a new one was on its was, just got to say how helpful Harry is, lots of knowledge and an even larger amount of new and used parts. New friction plate installed, looking swish. The adapter plate had been countersunk to accept the c/s bolts to give a flush surface for the gearbox to butt up to.

What does this say, any translators in?!  Sourced a push type clutch cover from LUK that suited. The locater holes needed drilling 0.5mm but thats it.I ordered a round type release bearing from sjs parts ready for the install.  |

| |

|

|

deanchad

Part of things

http://retrorides.proboards.com/thread/131936

http://retrorides.proboards.com/thread/131936

Posts: 142

|

|

|

|

So whilst the box and engine were apart I thought it was a good time to check the inner parts of the trans axle, no signs of fatigue, although the selector linkage had a little play. This play seemed small but resulted in much larger loose movement on the gear stick. small wear  gas welded and filed until tight in mechanism  .....  linkage finished off and tight.  Next, box partial strip  Intersting how this little channel feed the speedo gear and rear bearing and the peg holds the gear in position. Without it, the gear would fall off and cheer the box up!  ...  The Thermostat housing on the engine conversion needed to be moved from gearbox side to cam belt side, partly because the gearbox adaptor and partly for aesthetics. The only one I could find was damaged, so a repair was in order. rough old part and broken bolt/housing  Heated area and use Durafix to build up housing  installed bold and left to cool. Sanded and cleaned face and built up.  sorted   A little more modding needed to clear cam belt bearing later. |

| |

|

|

IDY

Part of things

Posts: 893

|

|

|

|

What does this say, any translators in?!  Asked the other half who complained bitterly about it being written in technical german - she thinks its warning you, due to the risk of damage in transit and storage, to check that it still with 0.5mm of true before fitting. |

| |

I will get round to finishing it at some point

|

|

|

|

I seem to remember reading up on 220bhp is the limit for the box. For the time being I will carry out a partial strip to check and run the box as it is, oil was clean and almost no filings either. Do you think the LSD will help, I could understand if I was going to track day it but on the roads?

I seem to remember reading up on 220bhp is the limit for the box. For the time being I will carry out a partial strip to check and run the box as it is, oil was clean and almost no filings either. Do you think the LSD will help, I could understand if I was going to track day it but on the roads?