Hi chaps, my name is Paul, thought i'd share my project with you, so hopefully some of you will find it informative or even mildly entertaining, we shall see!

I have owned my 944 for several years, she is a basic 2.5 NA and i really enoyed it until this happened.... a bus decided to not want to take a corner properly, locked up and took me clean out.

So she has been off the road for 18 months now while i fight this company to admit wrong doing.

Recently i have had the urge to bring her back to her former glory and beyond, being an engine conversion specialist by trade means i have all the tools and equipment (and a fair whack of knowledge) to make just about any engine

swap a reality, so it made sense to me to put a V8 in.

Now i have spent over a year researching and even parts buying, originally the plan was to use the Audi S8 motor, the AHC variant, in keeping with the Porsche heritage, i bought an engine, a 924 bellhosuing and an Audi V6

spacer plate to go between the 924 and AHC engine. We had even got as far as designing a new lower sump pan.

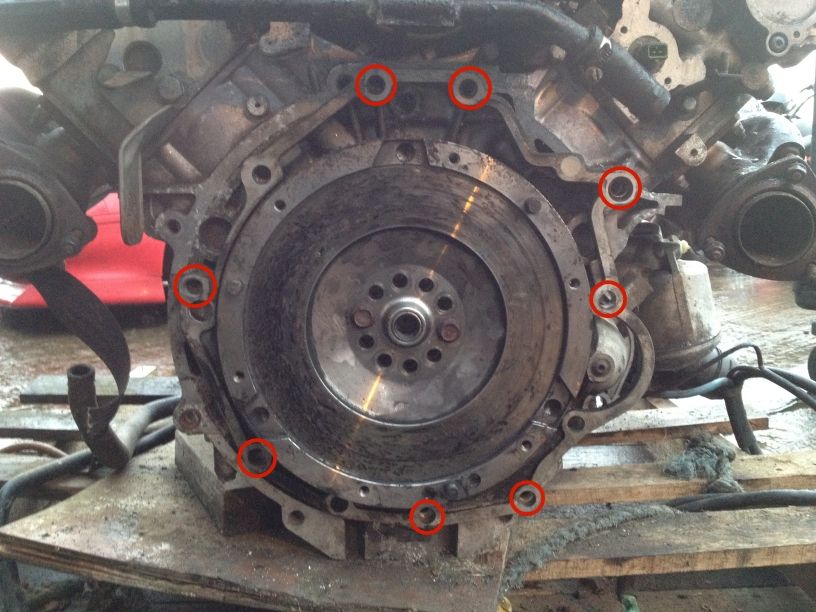

The 924 BH on the AHC, you can see it only picked up on 3 bolt holes...

Using the V6 spacer it gave a lot more attachment points....

Working with a friend of mine in the US we quickly discovered how insanely big the AHC is in the 944 bay....

We did get it sitting pretty....

But with serious sump pan and oil pump clearance issues to the rack....

We did a new oil pan in solidworks....

From there things went downhill, other stuff proved to be so difficult to get around we binned the Audi V8 route. So as you can see we've given this some serious thought.

I found a few threads showing a guy had already put a 1uz into a 944, and began researching that route, the 1uz is a monster and can be tuned to silly levels with bombproof internals.

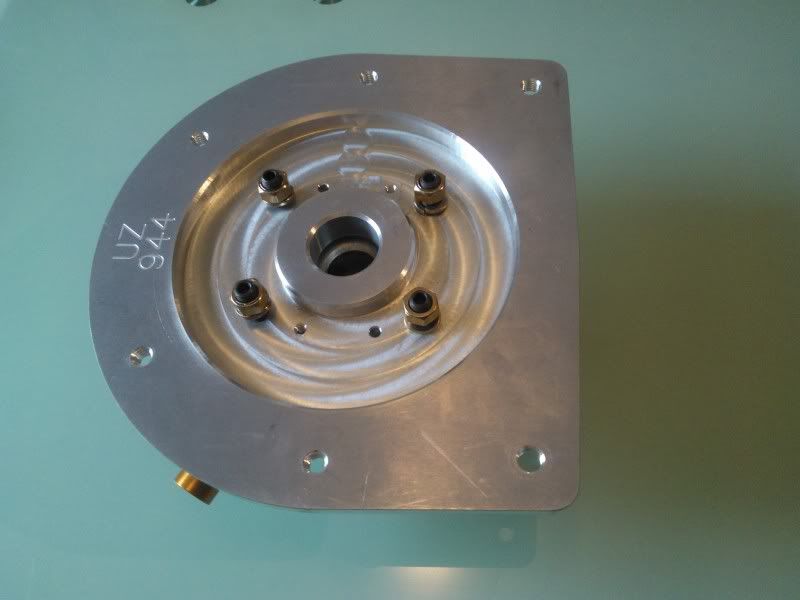

Last week i bought a complete 1uz and an adapter plate from XSchop in the US to mate it all to the 944 torque tube...

This uses the T56 clutch slave....

I will be using a modified Camry Fidanza flywheel with its ring gear reversed and an Mr2 turbo clutch pressure plate, an Audi V6 240mm 23 spline disc completes the drivetrain.

The car itself has had its 2.5 removed, bay gutted, cleaned and ready for hotwork.

Ok so as part of this swap the 944 brake servo gets in the way, and has to go, now some 944 V8 swappers just mount their master cylinder unassisted onto the firewall as a solution, but i want assisted brakes on this thing.

After a few hours research i found i can use the BMW 635 hydroboost system, it basically uses the power steering pump supply to aid braking, quite clever.

I realize putting a J engine into a 944 may not be everyones cup of tea, but i yearn for a V8 944 and for me the 928 engine is just too heavy and expensive, so hopefully i won't curse word too many purists off with my build, thanks for having me.

My Fidanza flywheel arrived so i removed the ring gear by heating it up, flipped it around and refitted it, this ensures the chamfer on the teeth faces the correct way for the Lexus starter motor....

Also my T56 clutch slave arrived, this will need extended pipes making to exit the Lexus bellhousing so that supply and bleed are taken care of, no biggy.

The V8 arrived, a bit manky but hey it's spent its whole life in an unloved LS400 engine bay, i'll make it good as new again.

I got to business and fitted the Fidanza flywheel, i have also removed the sump pan and lower sump casing in preparation for the first dummy fitting this weekend.

Once the dummy fitting and basic fabrication is out of the way this engine will get a complete teardown, overhaul and rebuild with a nice colour scheme to match the car

The adapter plate came from XSchop, and a nicely made item it is too, so i bolted it up to the 944 torque tube and attached my 1uz auto bellhousing, remember this is all just dummy fitting work at the moment, it all needs to come apart again for the final refit, this is just to carry out fabrication work in the engine bay etc.

Now the faint hearted among you may want to look away at this point, graphic 944 grinder action about to happen!

There is an area of bulkhead that fouls the V8, now something has to give, and the engine is not going to move out of the way, so this area of the firewall needs cutting out and remodelling....

This will be built up stronger than before but curved around the head of the V8 for clearance.

With no clutch fitted the engine swung straight into the bay and bolted up in minutes to the bellhousing...... et voila one V8 944....

Of course it isn't that simple, there is still a mountain of work to do, the Soarer sump i bought is not going to work at all, sometimes you have to spend money to find these things out, so i will be making my own sump from scratch. By this weekend the engine will be hanging on its new mounts and some real fabrication can begin, then by next week everything back apart for engine bay painting etc.

Those with a nervous disposition can uncover your eyes now

The engine mounts are now done, these still need final dressing before painting but plenty strong...

The mounts fitted to the engine...

And sitting on the Lexus rubbers which are bolted to the 944 subframe...

The subframe itself has been lowered 3/4" on these, very necessary for clearance....

Here you can see my new mounts, Lexus blocks and lowered subframe in the same shot...

Perfect alignment...

So i made a start on the new sump, i think i'm going to have 20-30 hours in the sump itself, it begins with a basic frame that i have bolted to the original sump pan, all very basic for now, this needs welding, trimming down and shaping before the next stage.

Final sump fabrication will take place on the engine block when it is mounted on the engine stand, but for now i can trial fit this frame between the subframe/rack and engine.

An interesting days fabrication work, i now have a bespoke 1uz/944 sump, it took 15 hours so not as bad as i was expecting.

As above i started with a basic frame mocked up on the original upper 1uz casing, that gave me the bolt hole positions are served as a jig to keep it all straight, avoiding distortion.

I decided to use the Soarer belly pan and incorporate that into the design, effectively making this as close to an original rear mounted sump as possible, so an angle frame was made with captive nuts...

This frame also gives me an extra 15mm of sump height which is about 3/4 ltr extra oil, the reason that is needed is because my "shallow" part of the sump is likely to hold less oil than normal. I then made a 30mm frame to act as the shallow part of the sump and as a structure to weld the belly pan frame to...

I then welded the belly pan tops onto the frame, it had to be done this way or i would not be able to seam weld it with the belly pan in place....

Brace in place preventing warping...

Belly pan section welded to upper part, you will see i also have a notch out of the shallow part for steering rack clearance...

The shallow pan base then added, with a scallop out of it for the rack hump it needs to clear...

Still need to add windage trays and surge channels to the inside.

Quick comparison, LS400 left, Soarer middle, 948 right.

And for good measure, Alfie (Woodsport dog) doing a spot of photobombing.

Still need to add dipstick tube, soda blast the entire thing to get rid of all metal particles before painting.

Level Zen fabrication completed.

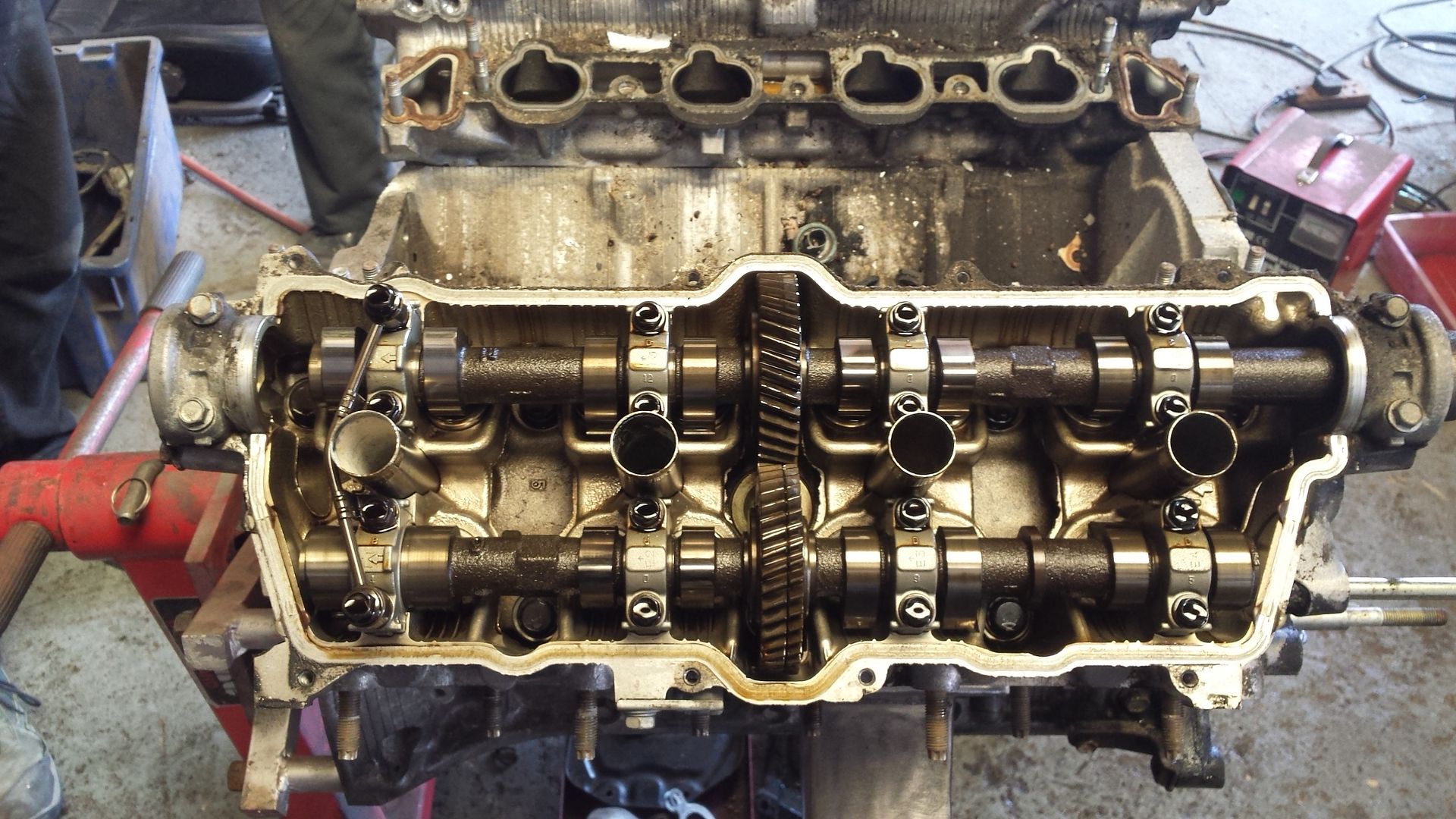

I stripped the V8 down to the bare bones, i have to say for a 1993 engine with over 100k on it i'm amazed by the condition of it all, this has been seriously looked after, perfect bores, you can still see the original honing marks...

The heads are near mint...

Internals are pretty spotless...

I was going to rebuild this engine but on inspection there really is no point, it's as fresh as they come, so it is getting a full degrease, new seals and gaskets, and a full detailing job....

I spent time on the cam covers getting them very clean and finished in Pepper white, a BMW mini shade that i think will look fantastic on the car, a real classic version of Old English white, so the whole car will be painted this colour. The engine will pick up on this colour with as much polished alloy as i can manage to give it that retro classic theme....

Car and engine... the goal is to complete the entire project by next May...

We're pretty busy right now! But held up waiting for parts on customers cars gives me the chance to catch up on my own stuff.

Not a bad finish at all...

Gasket set and head bolts ordered, along with cambelt and new idlers etc, pretty happy i don't have to fully rebuild it.

More hotwork got done in the engine bay, mostly because of the BMW Hydroboost system i am fitting to make sure my brakes work well, this unit sits very compactly compared to a regular servo system, but i did need to make room for it alongside the left strut tower which has been rebuilt with much thicker plate and supports in places you cannot see in these pics, i still have a lot of dressing to do, seam sealing and cosmetics before i can say it is ready for paint but it all fits now.

The brake bar has been extended and a new hanger bracket made for it, 10mm plate used to support the Hydroboost which is braced in several places, believe me there is no such thing as firewall flex now!

The 944 MC fits the BMW hydroboost with a little material removed....

Well outboard of the engine now....

So engine bay fabrication now all done, i had to make a notch in the left chassis rail for the power steering pump, but once done i seam sealed the bay, gave it a fresh primer coat followed by 4 coats of Pepper white, so the bay is now ready to receive the V8 for the final time...

Absolutely love this colour, very classic.

Very time consuming engine rebuilding, all 32 valve stem oil seals replaced, that's a job i never want to repeat... heads torqued down, cams refitted and covers fitted.

Moving on slowly but surely, i fitted the XSchop adapter and 1uz bellhousing today, modified the T56 release bearing pipes and bleed, made a new clutch line that will run from the 944 MC to the T56...

Tomorrow i will bleed the clutch and pressure test the system before my engine goes in, last thing i want is a leak on the pipes as it means the engine has to come back out.

My new aluminium radiator upgrade arrived today, so that got installed...

Also ordered camber adjustable top mounts and a set of Brembos from a Cayman 3.4 , they should stop it pretty well.

Spent today on more engine detailing and building, it's starting to become complete again....

New nuts/bolts used wherever possible....

Oil filter relocation adapter fitted....

Cambelt fitted along with water pump and oil pump...

Distributors/leads fitted...

As it is now...

Also built an awesome shot blasting cabinet from an old Pepsi fridge, this will see a lot of rusty 944 parts.

Today saw the sump finished, i had to make a new pickup pipe and get that routed to the new pan location...

The keener eyed will notice a flange just before the pickup, this was needed for assembly, it was not possible to make this as a one piece pickup.

I made a dipstick boss, drilled the pan, worked out my max/min levels and welded it in...

With the fabrication now finished everything was painted and assembled...

Maybe 45-50 hours work in that sump, madness!

Ok so new crankshaft oil seal fitted, Fidanza flywheel and clutch installed along with BMW spigot bearing (wow! a German part!)

Then with a little wiggling around this happened....

I appear to own a V8 944!

You can see the notch i needed to take out for the PS pump....

And although the BMW Hydroboost/944 brake master isn't cleaned/properly fitted yet you can see the clearance i now have, tight but workable....

Pretty happy to have got this far so quickly, now follows the really hard work.

More 948 nonsense...

The oil filter remote kit and cooler are now fitted, i have mounted the cooler behind the badge panel, and the plan is to vent the panel so that cold air hits directly in this area...

One of these designs will work well, anyone know who sells them? I can make one myself easily though.

Filter relocated here...

Radiator hoses connected....

On with the show, tonight i got the heater lines done, usually on any engine swap they are a simple matter of connecting A to B with rubber hose, but my 944 always suffered badly with faulty heater controls, to the point where i was getting fed up fixing it, you name it my 944 had that heater fault, i even thought about replacing the whole thing and i'm a mechanic!

Anyway as luck would have it i have no space under the bonnet for the stock control valve etc so with my car always blowing hot i can take this opportunity to ditch the Porsche way of controlling the heaters and use my own system, so i've used the complete heater valve and pipework from a Lexus Rx300 here which just happens to marry up very nicely with both the 1uz and 944 heater pipes.... so i'll run a cable from this and mount it under the dash binnacle somewhere.

No more heater problems for me ever again.

I've started mocking up the intake on this, very difficult to find space to route a 3" pipe from the throttle body to a suitable cold air location. One thing that has to go is the factory washer bottle, it just takes up too much vital space for this conversion, so i will fit a much smaller bottle somewhere else.

For now the intake navigates the strut tower, between the inner wing and headlight motor, and it will end up with the filter low down at the front where the washer bottle base used to be, it will need shielding from road curse word down there but it's the best place for it.

Been busy lately but some minor progress, intake now finished and plenum /throttle body detailed...

Ooh, controversial....

Time for an update, exhaust manifolds, we don't have any that work in a 944 with a 1uz fitted, the stock 1uz headers are.......well..... garbage!

So i've seen some attempts on the internet that made me roffle, log style....well logs are only fit for burning in my opinion, so i put a bit of thought into it and measured available space between the engine and chassis rails (it isn't a lot).

So with the brief to get some flow going, make them out of something more robust than tinfoil but ultimately fit in the space i have (flow can go screw itself if it means it not working at all) i set about with a big box of 45* and 90* steam pipe weld els, a 1uz 10mm thick header flange and a 2.5" output flange.....

About 25-30 man hours later we have this....

I'm very pleased with that, they are thick wall tube so will last forever, but i am only 50% of the way there, the amount of fabrication this took was insane.

I bolted the flange to a 3/4" thick plate of steel so that the welding would not pull or distort the flange, and it has ended up very straight.

Sadly none of this work will get seen from the engine bay, they are totally obscured, still i'm happy with that, one of the hardest things i've ever made.

Let us compare mine v the original LS400 one....

One down one to go!